A low-cost denitration catalyst and its manufacturing process

A denitration catalyst and manufacturing process technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as limited profit margins, high catalyst prices, and manufacturing cost constraints, and improve denitration performance. , the effect of increasing the specific surface area and improving the wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

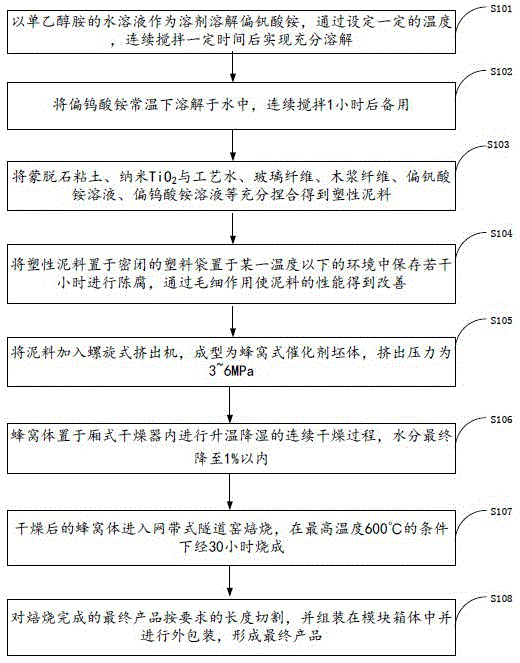

Image

Examples

specific Embodiment 1

[0028] Nano-TiO 2 Powder: 75%

[0029] Montmorillonite: 10%

[0030] Ammonium metatungstate: 6%

[0031] Ammonium metavanadate: 1%

[0032] Chopped glass fiber: 5%

[0033] Hardwood pulp fiber: 2%

[0034] Carboxymethylcellulose: 1.8%

[0035] Polyethylene oxide: 2%

[0036] Stearic acid: 1%

specific Embodiment 2

[0038] Nano-TiO 2 Powder: 70%

[0039] Montmorillonite: 15%

[0040] Ammonium metatungstate: 6%

[0041] Ammonium metavanadate: 1%

[0042] Chopped glass fiber: 4%

[0043] Hardwood pulp fiber: 2%

[0044] Carboxymethylcellulose: 1.5%

[0045] Polyethylene oxide: 1.6%

[0046] Stearic acid: 1%

specific Embodiment 3

[0048] Nano-TiO 2 Powder: 65%

[0049] Montmorillonite: 20%

[0050] Ammonium metatungstate: 6%

[0051] Ammonium metavanadate: 1%

[0052] Chopped glass fiber: 4.5%

[0053] Hardwood pulp fiber: 2%

[0054] Carboxymethylcellulose: 1.2%

[0055] Polyethylene oxide: 1.3%

[0056] Stearic acid: 1.2%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com