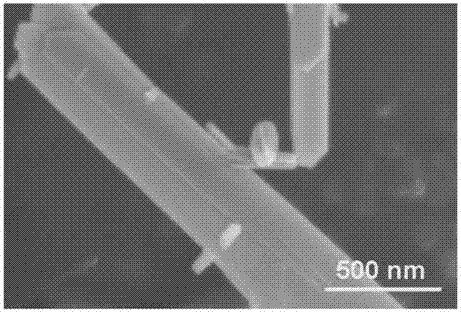

Controllable preparation method for high-power ultrasound-assisted nanoscale plate-shaped Fe3O4

An ultrasonic-assisted, nano-scale technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of uncontrollable nucleation and growth, narrow particle size distribution, etc. Controllable growth process, high crystallinity of particles, and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) FeCl 2 and NaOH were dissolved in distilled water respectively to form FeCl with a concentration of 0.50mol / L after dissolution 2 Solution and concentration are the NaOH solution of 15.60mol / L;

[0032] 2) The FeCl configured in step 1) 2 The solution is slowly dropped into the NaOH solution prepared in step 1), FeCl 2 The volume ratio of solution to NaOH solution is 2:5, and the titration rate is controlled at 0.5mL / min. During the dropping process, the NaOH solution was magnetically stirred, and the speed of the magnetic stirrer was controlled at 1200r / min to fully dissolve it;

[0033] 3) The mixed solution obtained in step 2) is assisted by high-power ultrasonic treatment, the ultrasonic power is 160W, the ultrasonic frequency is 32KHz, and the ultrasonic time is 30min, until the mixed solution is light green;

[0034] 4) Transfer the solution obtained in step 3) into a Teflon hydrothermal kettle with a filling ratio of 90%, and keep it warm for 9 hours at a ...

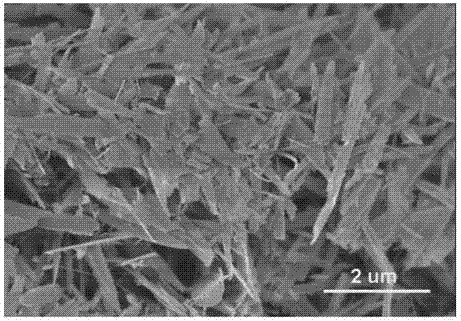

Embodiment 2

[0039] 1) FeCl 2 and NaOH are dissolved in distilled water respectively to form FeCl with a concentration of 0.2mol / L after dissolution 2 Solution and concentration are the NaOH solution of 12.60mol / L;

[0040] 2) The FeCl configured in step 1) 2 The solution is slowly dropped into the NaOH solution prepared in step 1), FeCl 2 The volume ratio of solution to NaOH solution is 2:5, and the titration rate is controlled at 1mL / min. During the dropping process, the NaOH solution was magnetically stirred, and the speed of the magnetic stirrer was controlled at 600r / min to fully dissolve it;

[0041] 3) The mixed solution obtained in step 2) is assisted by high-power ultrasonic treatment, the ultrasonic power is 100W, the ultrasonic frequency is 20KHz, and the ultrasonic time is 25min, until the mixed solution is light green;

[0042] 4) Transfer the solution obtained in step 3) into a Teflon hydrothermal kettle with a filling ratio of 80%, and keep it warm for 12 hours at 200°C;...

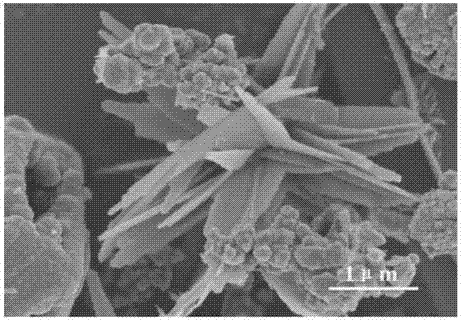

Embodiment 3

[0047] 1) FeCl 2 and NaOH were dissolved in distilled water respectively to form FeCl with a concentration of 2.00mol / L after dissolution 2 Solution and concentration are the NaOH solution of 15.80mol / L;

[0048] 2) The FeCl configured in step 1) 2 The solution is slowly dropped into the NaOH solution prepared in step 1), FeCl 2 The volume ratio of solution to NaOH solution is 2:5, and the titration rate is controlled at 2.0mL / min. During the dropping process, the NaOH solution was magnetically stirred, and the speed of the magnetic stirrer was controlled at 1000r / min to fully dissolve it;

[0049] 3) The mixed solution obtained in step 2) is assisted by high-power ultrasonic treatment, the ultrasonic power is 150W, the ultrasonic frequency is 30KHz, and the ultrasonic time is 20min, until the mixed solution is light green;

[0050] 4) Transfer the solution obtained in step 3) into a Teflon hydrothermal kettle with a filling ratio of 70%, and keep it warm for 20 hours at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com