Method for preparing pholiota nameko cultivation material through utilization of pecan production and processing waste

A technology for the cultivation of oyster mushrooms and pecans, which is applied in the preparation of organic fertilizers, the treatment and application of bio-organic parts, and can solve the problems of polluting the environment, difficult recycling of fruit shells, and increasing production costs, and achieve good growth and water retention. strong, growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

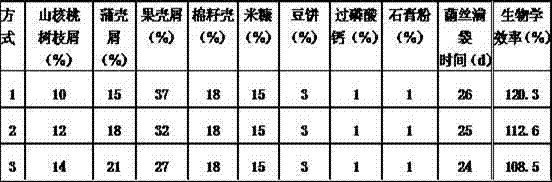

[0029] Mode 1: In this embodiment, the cultivation material of Pleurotus ostreatus includes the following components and mass ratio: 10% of hickory tree branch chips, 15% of cattail shell chips, 37% of fruit shell chips, 18% of cottonseed shells, 15% of rice bran, and 3% of bean cakes %, 1% superphosphate, and 1% gypsum powder, all of which are the quality of dry matter, and the sum of the ratios is 100%.

[0030] Production Method:

[0031] ①Sunning: Expose the raw materials to the sun for 2 days before mixing, use ultraviolet light to kill some bacteria in the raw materials, and at the same time decompose and volatilize the antibacterial substances;

[0032] ②Pre-wet: First, mix the hickory branch chips, cattail shell chips, and fruit shell chips evenly in a dry state, and then pre-wet with water (fully soaked);

[0033] ③ Stacking fermentation: Pile the wet material into a trapezoidal pile with a height of 1.2 m, a width of 3 m, and a length of 5 m. At the bottom of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com