Device and method for extracting V<E> (vitamin E) in enhanced manner by means of ultrasonically pre-treating deodorized and distilled products of plant oil

A technology of deodorizing distillate and ultrasonic pretreatment, applied in the fields of biofuel, organic chemistry, petroleum industry, etc., can solve the problem of long extraction time, and achieve the effect of shortening extraction time, continuous production and improving preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

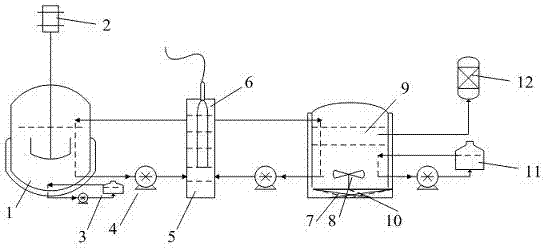

[0025] Enhanced extraction of soybean oil deodorized distillate by ultrasonic pretreatment V E . exist figure 1 In transesterification reaction tank 1, KOH 1% (accounting for the amount of distillate) under alkali catalysis conditions, 35 ° C, alcohol-oil ratio (V / W) 8:1, stirring device 2 stirring 150 rpm, soybean oil deodorization distillate in 1 reaction in the transesterification reaction tank, the reaction mixture is pumped into the external circulation reactor 5 through the circulation pump 4, is ultrasonically strengthened and then continuously circulated and pumped into the transesterification reaction tank 1, the ultrasonic power is 300 W, and the ultrasonic frequency is 28 kHz. Pump at 4 speeds, and maintain sonication for 10 min. The soybean oil deodorized distillate through transesterification, after being further ultrasonically treated in the external ultrasonic reactor 5, is continuously pumped into the cold crystallization reaction tank 7 through the circulati...

Embodiment 2

[0027] Extraction of rapeseed oil deodorization distillate by ultrasonic pretreatment E ,Such as figure 1 As shown in the device, the conversion of deodorized distillate and ethanol to biodiesel under the condition of lipase catalysis was compared with that of ordinary non-ultrasonic enzymatic method. The reaction temperature of the deodorized distillate in the transesterification tank 1 is 60°C, the ratio of alcohol to oil (V / W) is 1:1, the amount of enzyme added is 10%, the stirrer device 2 is stirred at 150 rpm, and the reaction mixture in the transesterification tank 1 passes through The circulating pump 4 is pumped into the external circulating ultrasonic reactor 5 to be ultrasonically strengthened, and then pumped into the transesterification reaction tank 1 through the pump 4 to complete the transesterification reaction, and the ultrasonic reaction time is 180 min. The ultrasonic power is 300 W, and the ultrasonic frequency is 28 kHz. The rapeseed oil deodorization di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com