Natural gas compression energy saving technology of CNG (compressed natural gas) station

A gas filling station, natural gas technology, applied in gas fuel, petroleum industry, gas/liquid distribution and storage, etc., can solve problems such as increasing operating costs, increasing cooling water flow resistance, and deteriorating cooling water quality, reducing operation and Effectiveness of managing costs, increasing effective inhalation, avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

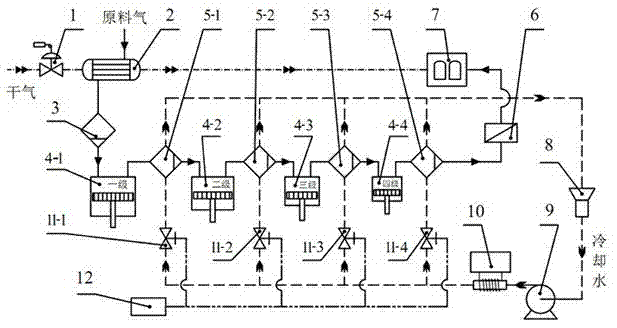

[0015] In order to further illustrate the process of the present invention, it will be described below in conjunction with the accompanying drawings and examples.

[0016] The design output of CNG filling station is 1.2×10 4 N m 3 / d, the inlet pressure of raw material gas is 0.35MPa; two L-type four-stage compressors are used, the power of each compressor is 132KW, the design suction pressure is 0.5MPa, the inlet temperature is 0-35℃, the gas supply volume 650Nm 3 / h; the frequency conversion motor is equipped with a power of 132KW; the cooling water volume of the cooling water tower is 23.4m 3 / h; The configuration power of the electromagnetic descaling instrument is 8W.

[0017] The raw material gas with a pressure of 0.35MPa is firstly input into the shell side of the heat exchanger 2 for pre-cooling, the temperature is cooled to -10°C, and then input into the separator 3 to remove free water and condensate impurities, and the shallow dehydration of the raw material gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com