Foam products, floating structures and their construction materials

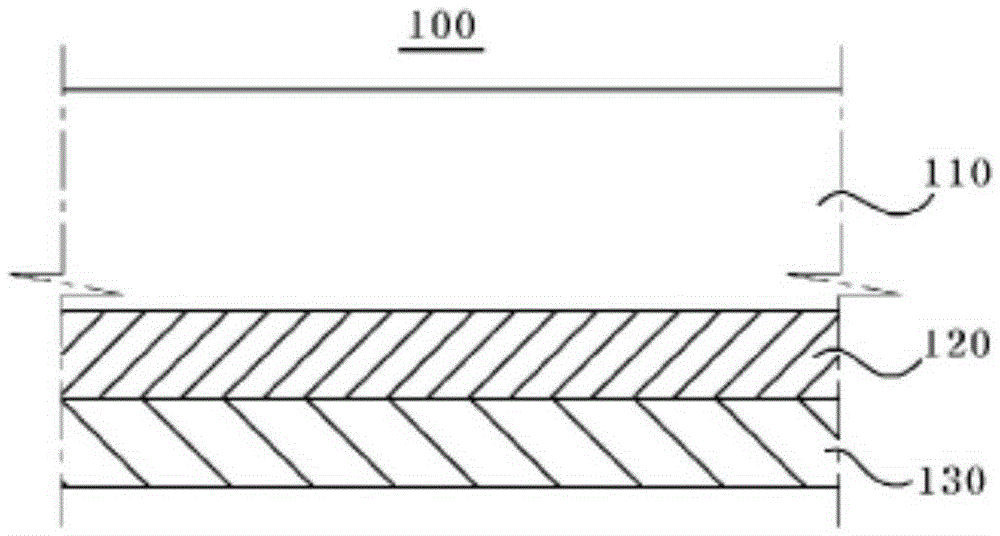

A product, foam technology, applied in the field of floating structures and construction materials, can solve the problems of frequent collapse accidents of retaining walls and stone structures, difficulty in obtaining natural aggregates, a lot of cost and time, etc., to improve floatability and recovery. force, bulletproof explosion-proof weight, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0139] The present invention can be more fully understood by reference to the following exemplary embodiments. The following exemplary embodiments are provided for exemplary purposes of the present invention. The present invention should not be construed as being limited to the scope of protection defined by the claims set forth in this specification.

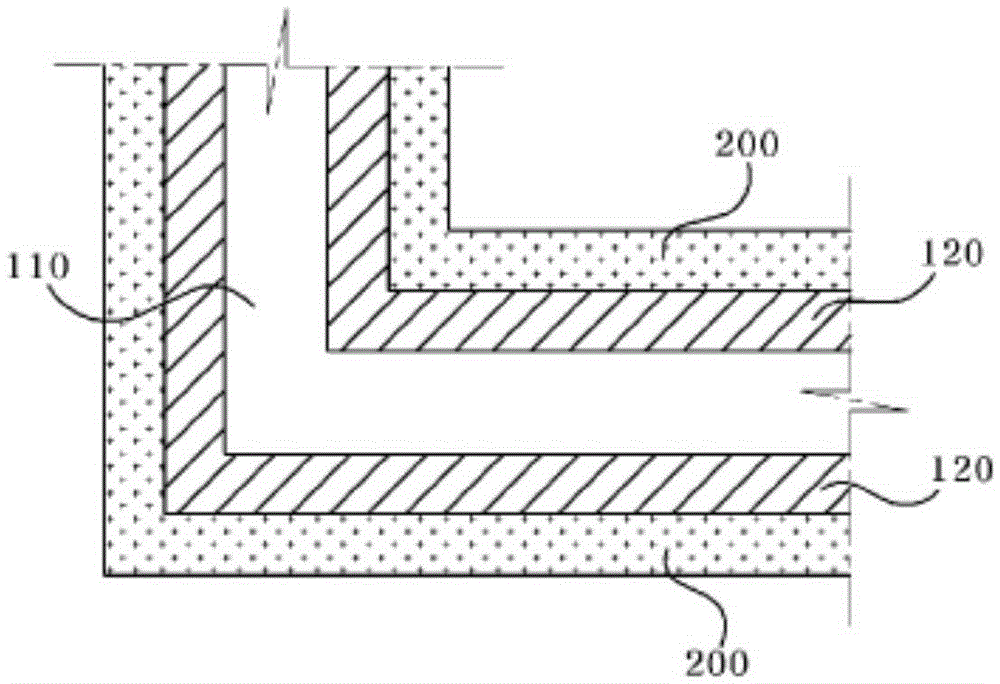

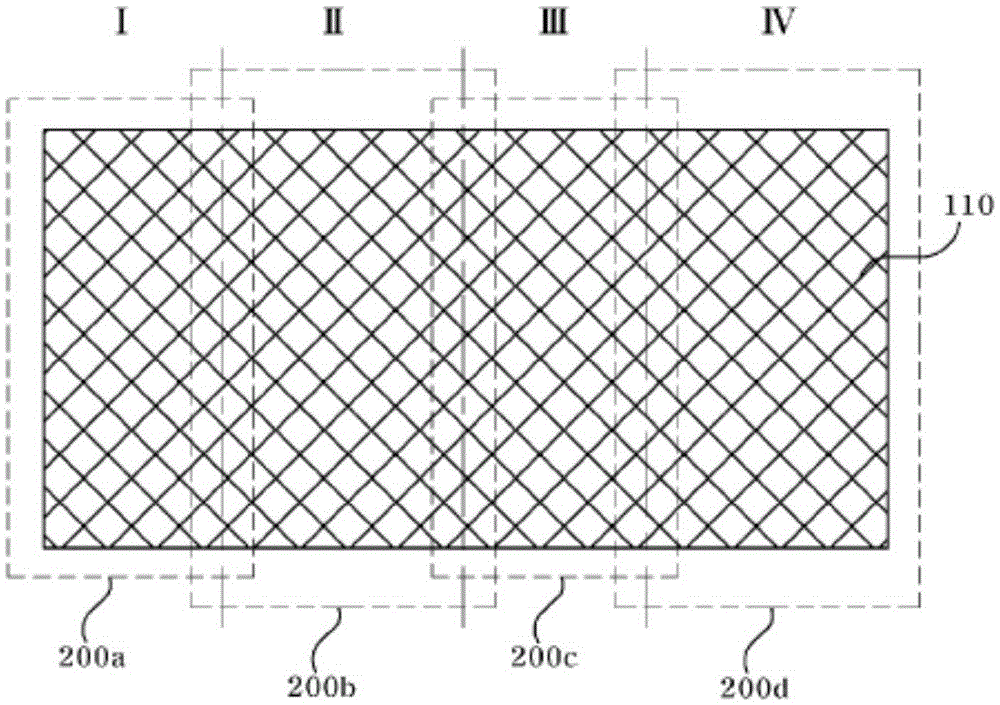

[0140] Polyurea is coated on the surface of the foam, wherein polyurea is also used as a raw material for the adhesive due to its strong consistency. Specifically, the polyurea contains the same components (for example, isocyanate) as polyurethane so that physical and chemical continuity is excellent. Thereby, the polyurea of the present invention is superior in cohesive force (adhesion energy), mechanical strength, tensile strength, elasticity, impact resistance and UV resistance with respect to the coating of polyurea on other usual materials. Coating can be greatly improved. Polystyrene also exhibits excellent consisten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com