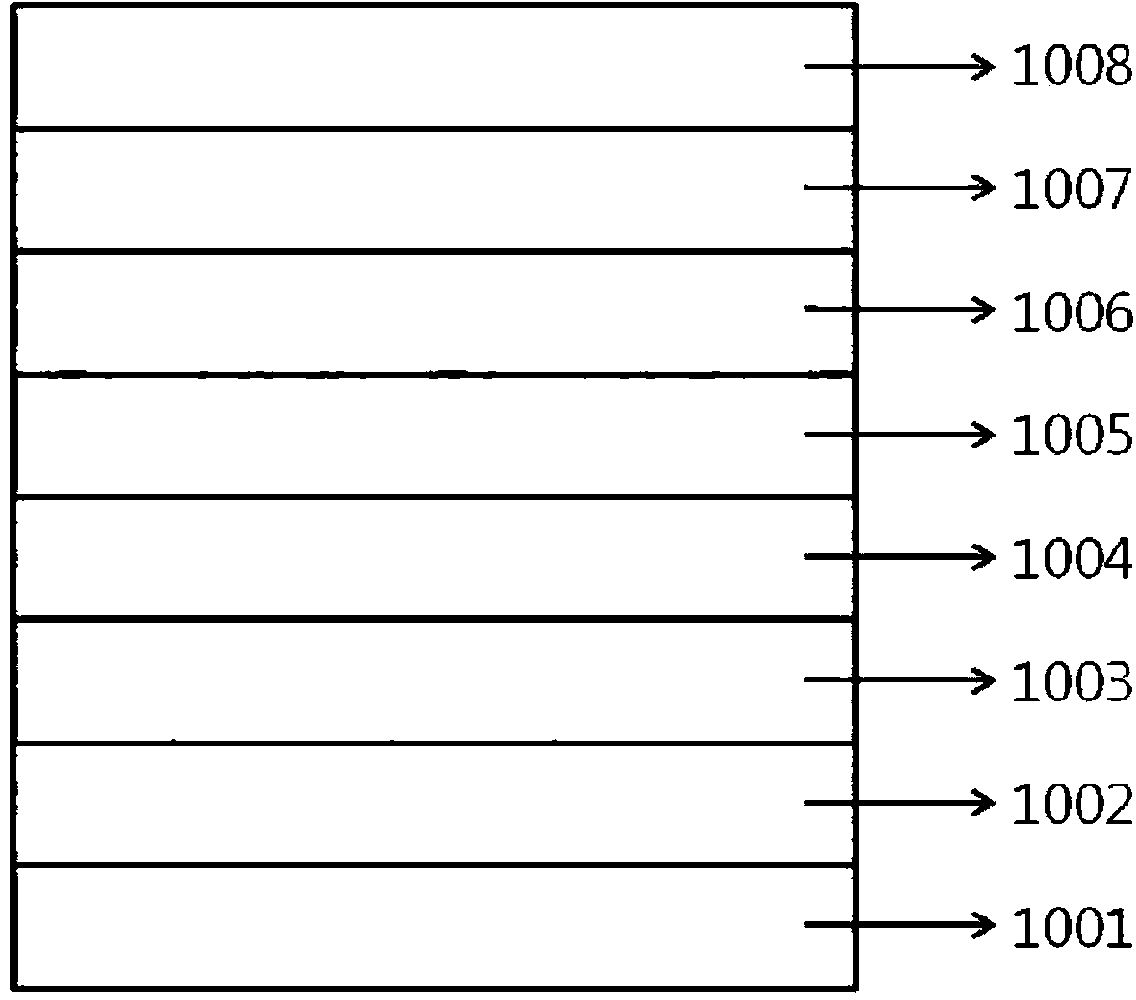

Metal oxide semiconductor electrode having porous thin film, dye-sensitized solar cell using same, and method for manufacturing same

An oxide semiconductor and solar cell technology, applied in semiconductor devices, electrolytic capacitors, final product manufacturing, etc., can solve the problems of inability to generate photoelectrons, control photoelectron recombination reactions, and reduce DSSC efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

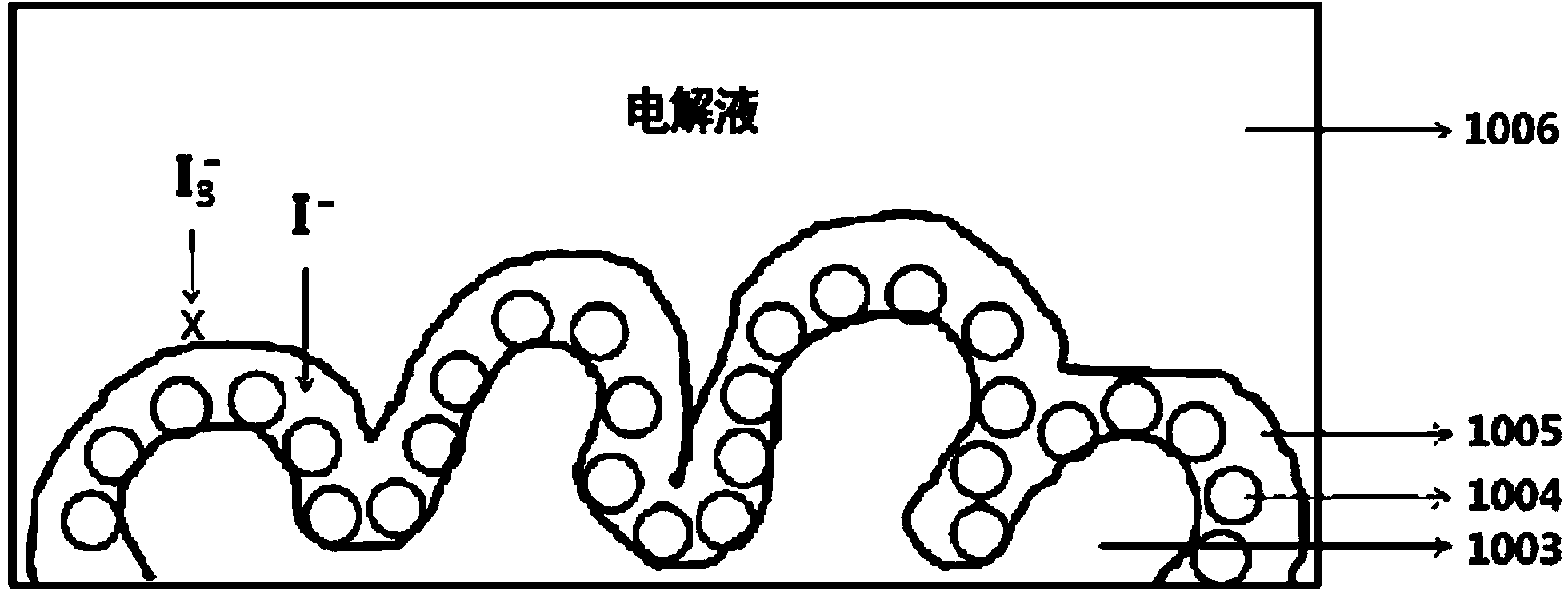

[0067] The titanium dioxide (dye) porous film-forming composition was coated on a transparent glass substrate coated with fluorine-doped indium tin oxide with a substrate resistance of 15Ω / □ by doctor blade film-forming method. After drying, heat treatment was performed at 500° C. for 30 minutes to form a porous film made of titanium dioxide. The thickness of the porous membrane prepared at this time was about 6 μm. Afterwards, the first electrode forming the porous membrane was soaked in acetocyanide and tert-butanol (1:1 volume ratio) as a solvent, and 0.30 mM ruthenium (4,4-dicarboxy-2,2' -dipyridine) 2 (NCS) As a dye, 0.30 mM methacryloyl-4-aminobutyric acid (methacryloyl-4-aminobutyric acid) was soaked in a solution as a co-adsorbent for 18 hours to adsorb the dye on the porous membrane. Afterwards, a solution is coated on the first electrode on which the dye and the co-adsorbent are adsorbed on the porous membrane. solution, followed by crosslinking at 80 °C for 30 mi...

Embodiment 2

[0071] In addition to dissolving 0.8M 1-butyl-3-methylimidazolium iodine and 0.03M concentration of iodine and 0.2M 4-tert-butylpyridine in the solvent of methoxypropionitrile, the remaining steps All the same as in Example 1.

Embodiment 3

[0073] Except for using a mixed solution of methyl methacrylate and 1,6-hexanediol diacrylate at a ratio of 4 as the electrolyte, and re-crosslinking the electrolyte to prepare a quasi-solid-state dye-sensitized solar cell, the rest of the steps were performed uniformly Example 2 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com