A kind of preparation method of double anti-pollution ultrafiltration membrane

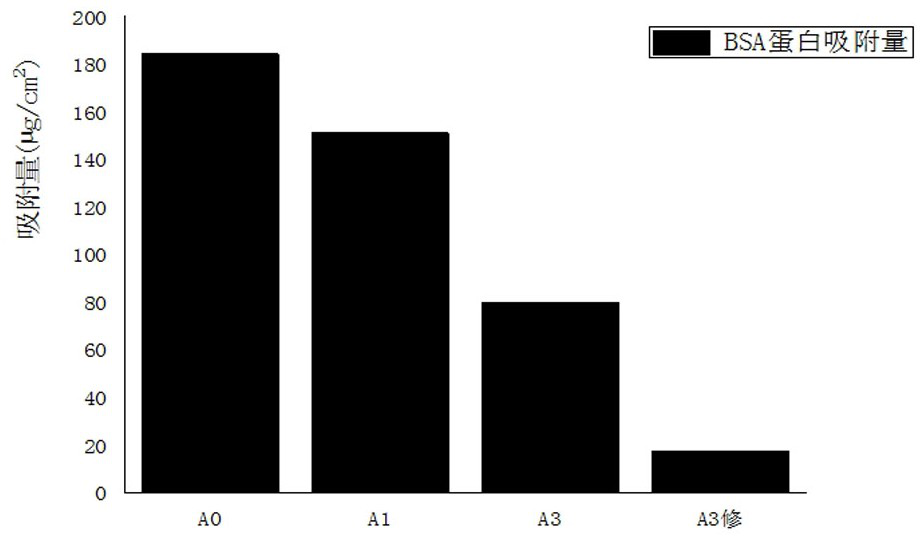

An anti-pollution, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve the problem of limited doping amount of hydrophilic polymers, difficult modification of polysulfone molecules, and decreased membrane stability. problems, to achieve the effect of improving anti-pollution performance, controllable reactivity, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

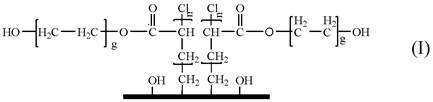

[0041] Embodiment 1: Preparation of chloromethylated polysulfone

[0042] Weigh 14.88 g polysulfone and dissolve in 750 mL CHCl 3 10 g paraformaldehyde, 395 µL SnCl 4 , and then dropwise added 45 mL of trimethylchlorosilane to a 1000 mL three-neck round bottom flask. After the dropwise addition, put the mixed solution on the oil pan for reaction, set the temperature at 65 °C, react for 72 h, and put on the reflux device. After the reaction was completed, the solution was poured into a beaker, then cooled to room temperature, precipitated with methanol, and dried by suction filtration. The dried solid was dissolved in chloroform, ultrasonically dissolved, reprecipitated, washed three times with methanol, placed in a vacuum oven at 50°C for 24 hours to obtain purified chloromethylated polysulfone.

Embodiment 2

[0043] Embodiment 2: preparation polyethylene glycol acrylate

[0044] Put 80 g of dry polyethylene glycol-400 and 30 mL of triethylamine in 300 mL of dry dichloromethane, cool in an ice-water bath, and dissolve in 130 mL of dry dichloromethane drop by drop under nitrogen atmosphere acryloyl chloride (12.2 mL). After mechanical stirring at room temperature for 24 hours, the reaction mixture was cooled at 273 K and the salts were filtered off using a Buchner funnel.

[0045] Wash with 200 mL HCl (2 M) at the end of the reaction, and wash with 200 mL HCl 2 O and NaHCO 3 (1M), and 200 mL of NaCl were dried over magnesium sulfate and the solvent was evaporated in vacuo. The crude product (30 g) was dissolved in 100 mL of distilled water and extracted twice with diethyl ether (2×50 mL), keeping the aqueous phase. Extract the aqueous phase stepwise with a 3:1 mixture of dichloromethane / n-hexane (40 mL×2), add magnesium sulfate to the organic phase to dry, pass through degreased ...

Embodiment 3

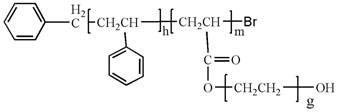

[0046] Embodiment 3: prepare polystyrene

[0047] Add 38 mL of styrene, 430 µL of benzyl bromide, and 1.686 g of bipyridine into a 100 mL three-necked flask, directly quench with liquid nitrogen, add liquid nitrogen to the cold hydrazine, open the air in the pumping line, and then At room temperature, turn on the oil pump to evacuate (10-15 min), open the nitrogen valve, and first pass in N 2 , and then thawed with warm water, repeat 2 times. When thawing for the second time, weigh 0.516 g CuBr, put it into a three-necked flask after it is completely thawed, quench it with liquid nitrogen, pump it with an oil pump at room temperature (10-15 min), and first pass N 2 , and then thawed with warm water, repeat 2 times. After the solution was thawed, put the oil pan on the shelf, set the temperature to 110 °C, react for 12 h, and stir with magnetic force. After the reaction was completed, it was diluted with THF and filtered with a Buchner funnel to remove CuBr which was not rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com