Production method of low-temperature defatted peanut protein gel food

A low-temperature degreasing, peanut protein technology, applied in the direction of plant protein processing, etc., can solve the problems of loss of use value, waste of protein resources, use as feed or fertilizer, etc., to protect edible value, improve enterprise economic benefits, and save production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The method for producing low-temperature defatted peanut protein gel food in this embodiment includes the following steps:

[0031] (1) Pour the low-temperature defatted peanut meal powder and 35°C warm water into the hot and cold cylinder together, and start stirring at 125r / min for 20 minutes to make the mixing uniform; the weight ratio of the peanut meal powder to warm water is 1:10;

[0032] (2) Separate the resulting mixing liquid in a slurry centrifuge, the centrifuge drum speed is 1450r / min, the drum screen is 120 mesh, the obtained slurry is ready for use, the obtained slag is ground and then recycled in step (1) twice use;

[0033] (3) Heat the slurry obtained by centrifugation, the heating temperature is 100°C, and the time is 20 minutes;

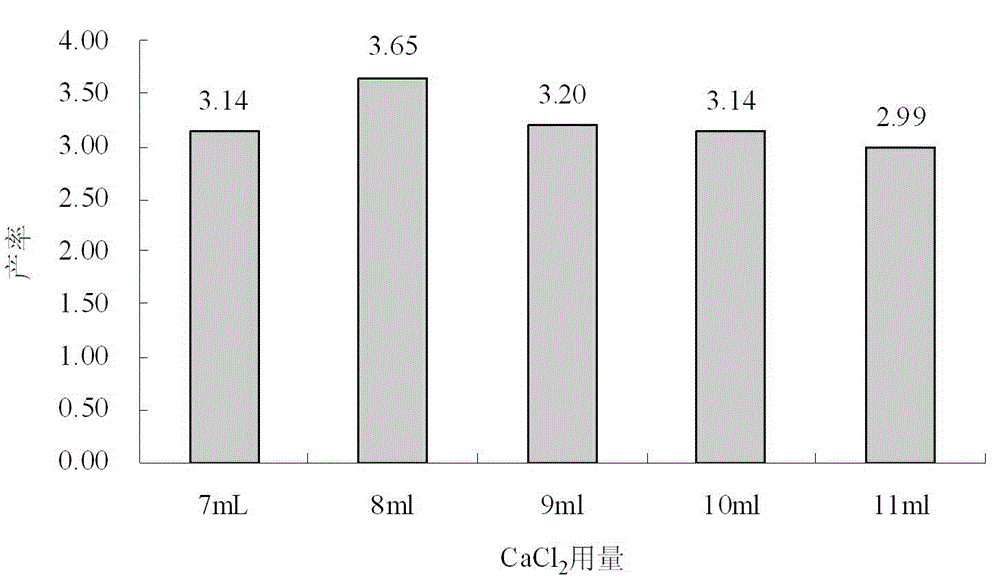

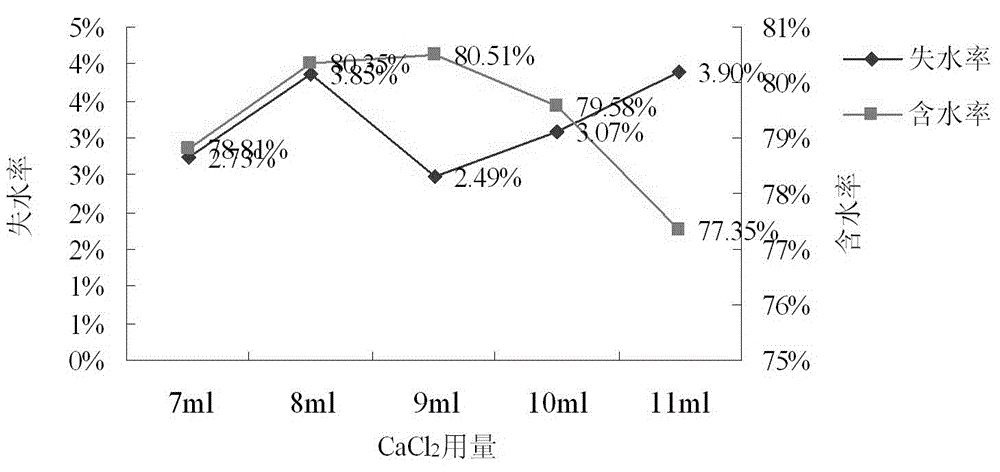

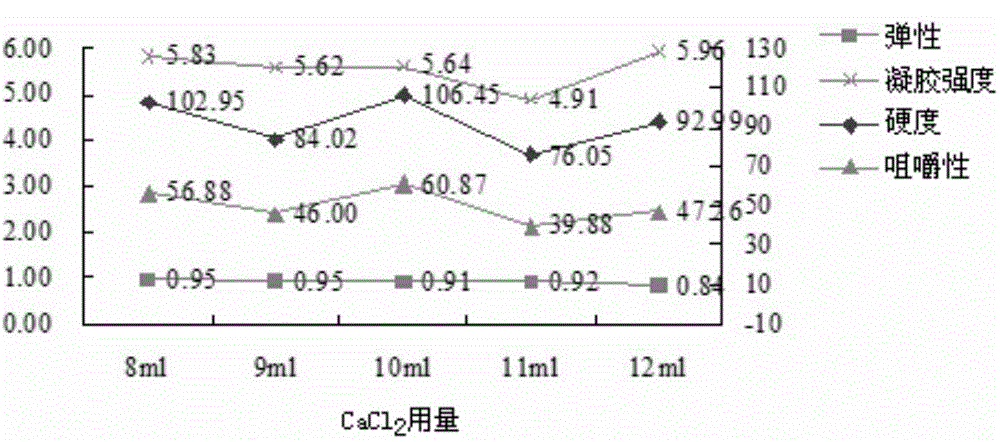

[0034] (4) When the slurry is cooled to 85°C, do spotting, and add 9mL CaCl according to the amount of 1000L slurry 2 Solution, and stirring at the same time, rotating speed 60r / min, make the slurry and CaCl 2 Mix well, stop stirri...

Embodiment 2

[0043] The method for producing low-temperature defatted peanut protein gel food in this embodiment includes the following steps:

[0044] (1) Pour the low-temperature defatted peanut meal powder and 32°C warm water into the hot and cold cylinder together, and start stirring at 120r / min for 15min to make the mixing uniform; the weight ratio of the peanut meal powder to warm water is 1:8;

[0045] (2) Separate the obtained mixing liquid in a slurry centrifuge, the centrifuge drum speed is 1400r / min, drum screen 115 mesh, the obtained slurry is ready for use, the obtained slag material is ground and then recycled in step (1) twice use;

[0046] (3) Heat the slurry obtained by centrifugation, the heating temperature is 95℃, and the time is 15min;

[0047] (4) When the slurry is cooled to 80°C, do spotting, and add 8mL CaCl according to the amount of 1000L slurry 2 Solution, and stirring at the same time, rotating speed 50r / min, make the slurry and CaCl 2 Mix well, stop stirring when a br...

Embodiment 3

[0052] The method for producing low-temperature defatted peanut protein gel food in this embodiment includes the following steps:

[0053] (1) Pour the low-temperature defatted peanut meal powder and 38°C warm water into the hot and cold cylinder together, and start stirring at 130r / min for 20min to make the mixing uniform; the weight ratio of the peanut meal powder to warm water is 1:12;

[0054] (2) Separate the obtained mixing liquid in a slurry centrifuge, the centrifuge drum speed is 1500r / min, the drum screen is 125 mesh, the obtained slurry is ready for use, the obtained slag material is ground and then recycled in step (1) twice use;

[0055] (3) Heat the slurry obtained by centrifugation, the heating temperature is 100°C, and the time is 20 minutes;

[0056] (4) When the slurry is cooled to 90℃, do the spotting, and add 10mL CaCl according to the amount of 1000L slurry 2 Solution, and stirring at the same time, rotating speed 80r / min, make the slurry and CaCl 2 Mix well, stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com