Waste gas washing treatment method and device in polycrystalline silicon industry

A water washing treatment, polysilicon technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of difficult removal of silicon dioxide solids, environmental pollution, and difficulty in sewage treatment, reducing the escape of hydrogen chloride and solving the danger. and hazard, the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

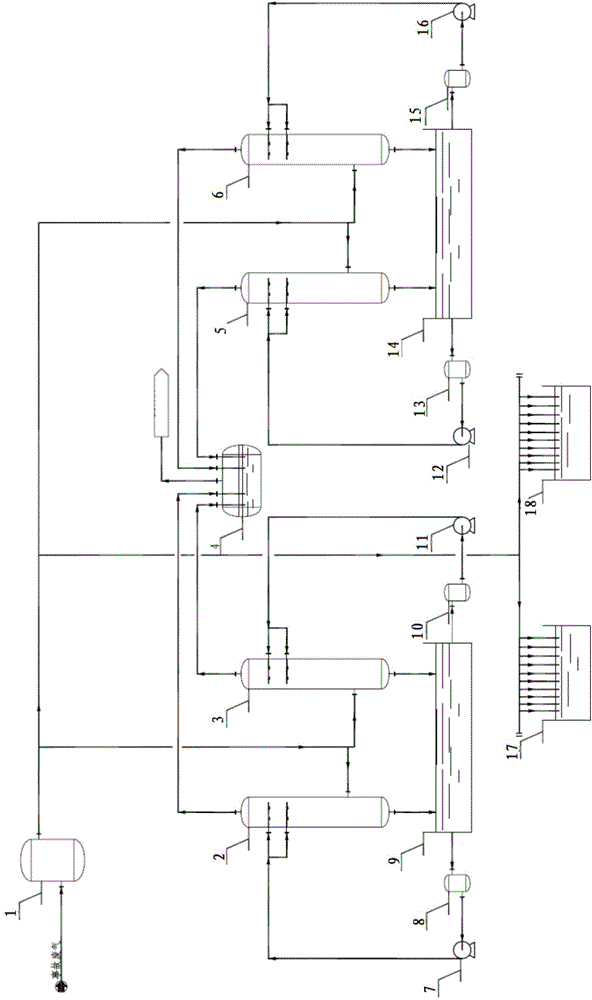

[0027] like figure 1 As shown, a method and device for washing waste gas in the polysilicon industry according to the present invention includes a waste gas buffer tank 1, a chlorosilane waste gas supply pipeline connected to the inlet of the waste gas buffer tank 1, and an outlet of the waste gas buffer tank 1 Connected normal exhaust gas spraying system, accident exhaust gas spraying system and emergency water washing system;

[0028] The normal exhaust gas spraying system includes normal exhaust gas spraying tower one 2 and normal exhaust gas spraying tower two 6, siphon tank one 8 and siphon tank two 15, normal exhaust gas spray circulation pump one 7 and normal exhaust gas spray tower circulation Pump two 16, lye pool one 9 and lye pool two 14; Wherein, the outlet of waste gas buffer tank 1 links to each other with the entrance of normal waste gas spray forest tower one 2, and the outlet of normal waste gas spray forest tower one 2 is connected with lye pool one The inle...

Embodiment 2

[0038] A method for washing waste gas from the polysilicon industry, comprising the following steps:

[0039] (a) The waste gas containing chlorosilane is transported to the waste gas buffer tank 1 through the waste gas supply pipeline containing chlorosilane, and then the waste gas is transported to the normal waste gas spraying tower 1 through the waste gas supply pipeline, and the waste gas runs in the tower from bottom to top Deposit 10~30% lye in the lye pool-9, and lye is sent to the top of the normal waste gas spray forest tower-2 tower by the normal exhaust gas spraying circulation pump-7 through the siphon tank-8 as spray liquid, sprays The liquid is in countercurrent contact with the waste gas from top to bottom, and the treated gas is discharged into the atmosphere through the water-sealed tank 4 on the top of the normal waste gas spraying tower-2;

[0040] The chlorosilane waste gas is transported to the waste gas buffer tank 1 through the chlorosilane waste gas su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com