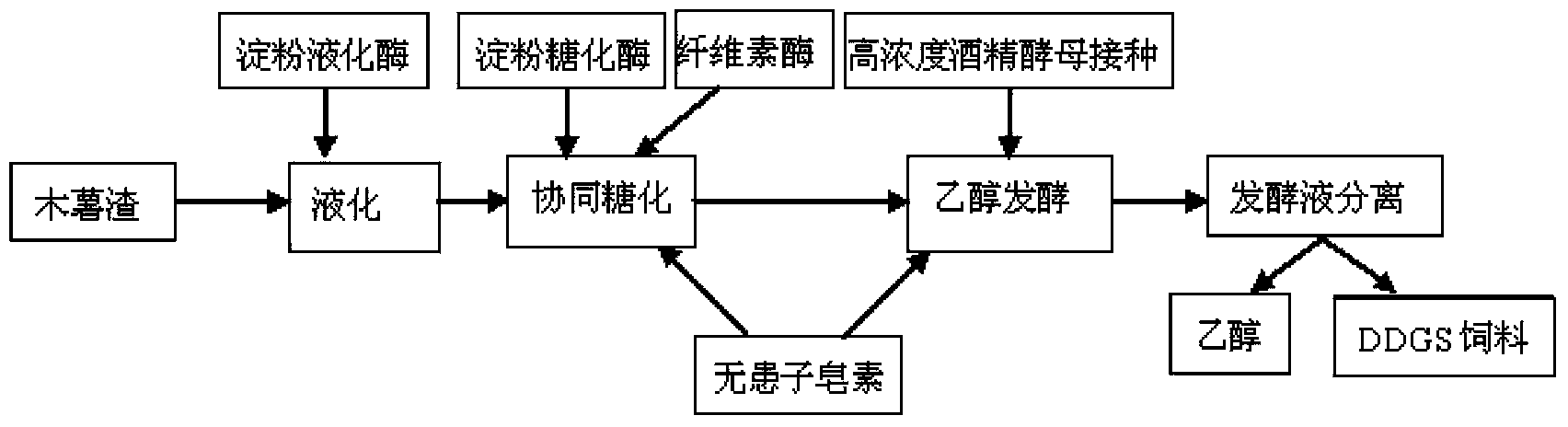

Method for preparing ethanol with manioc wastes as raw materials through synergic saccharification fermentation

A technology for saccharification fermentation and cassava residues, applied in biochemical equipment and methods, microorganism-based methods, fermentation and other directions, can solve the problems of high energy input and high cost of separation and purification, and achieve improved saccharification effect, hydrolysis efficiency and price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Add 1 kg of cassava dregs to 50°C water, keep it warm for 30 minutes, then add starch liquefying enzyme, and liquefy at 90°C for 2 hours under stirring conditions to obtain cassava dregs starch liquid; the weight volume percentage of cassava dregs and water is 15w / v %; The amount of starch liquefaction enzyme added is 8U / gram of cassava residue;

[0029] 2) Use 10% dilute sulfuric acid to adjust the pH value of the above tapioca dregs starch solution to 4.5, add starch glucoamylase, cellulase, and sapindus saponin, and saccharify at 48°C for 12 hours to obtain a saccharification solution; the amount of starch glucoamylase added is 60U / gram of cassava residue; the amount of cellulase added is 3.0FPU / gram of cassava residue; the weight volume percentage of sapinberry saponin and cassava residue starch liquid is 0.08w / v%;

[0030] 3) After adjusting the pH value of the cassava dregs saccharification solution to 6.0 with 10% sodium hydroxide, fill the saccharification so...

Embodiment 2

[0040] Ethanol was prepared by fermentation according to the method of Example 1. Among them, 1 kg of cassava residues is used as raw material, and the weight volume percentage of cassava residues and water is 23w / v%; the amount of starch liquefaction enzyme added is 10U / gram of cassava residues; the amount of starch glucoamylase added is 70U / grams of cassava residues; fiber The amount of suzyme added is 4.0 FPU / gram of cassava dregs; the weight volume percentage of sapinberry saponin and tapioca dregs starch liquid is 0.12w / v%; w / v%; Alcoholic yeast is a high-temperature resistant type of alcoholic yeast, and the inoculum concentration is 7.5g / L.

Embodiment 3

[0049] Ethanol was prepared by fermentation according to the method of Example 1. Among them, 1 kg of cassava residues is used as raw material, and the weight volume percentage of cassava residues and water is 20w / v%; the addition amount of starch liquefying enzyme is 6U / per gram of cassava residues; the addition amount of starch glucoamylase is 50U / per gram of cassava residues; The amount of suzyme added is 1.0 FPU / gram of cassava dregs; the weight volume percentage of sapinberry saponin and tapioca dregs starch liquid is 0.01w / v%; w / v%; Alcoholic yeast is a high-temperature resistant type of alcoholic yeast, and the inoculum concentration is 5.5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com