Weld joint force applying device and method using same for improving form and performance of weld joint

A force-applying device and form technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of a lot of time and labor costs, difficulty in selecting welding process parameters, harsh grinding conditions, etc., to eliminate Defects, improved impact energy, uniform and dense effect inside the weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

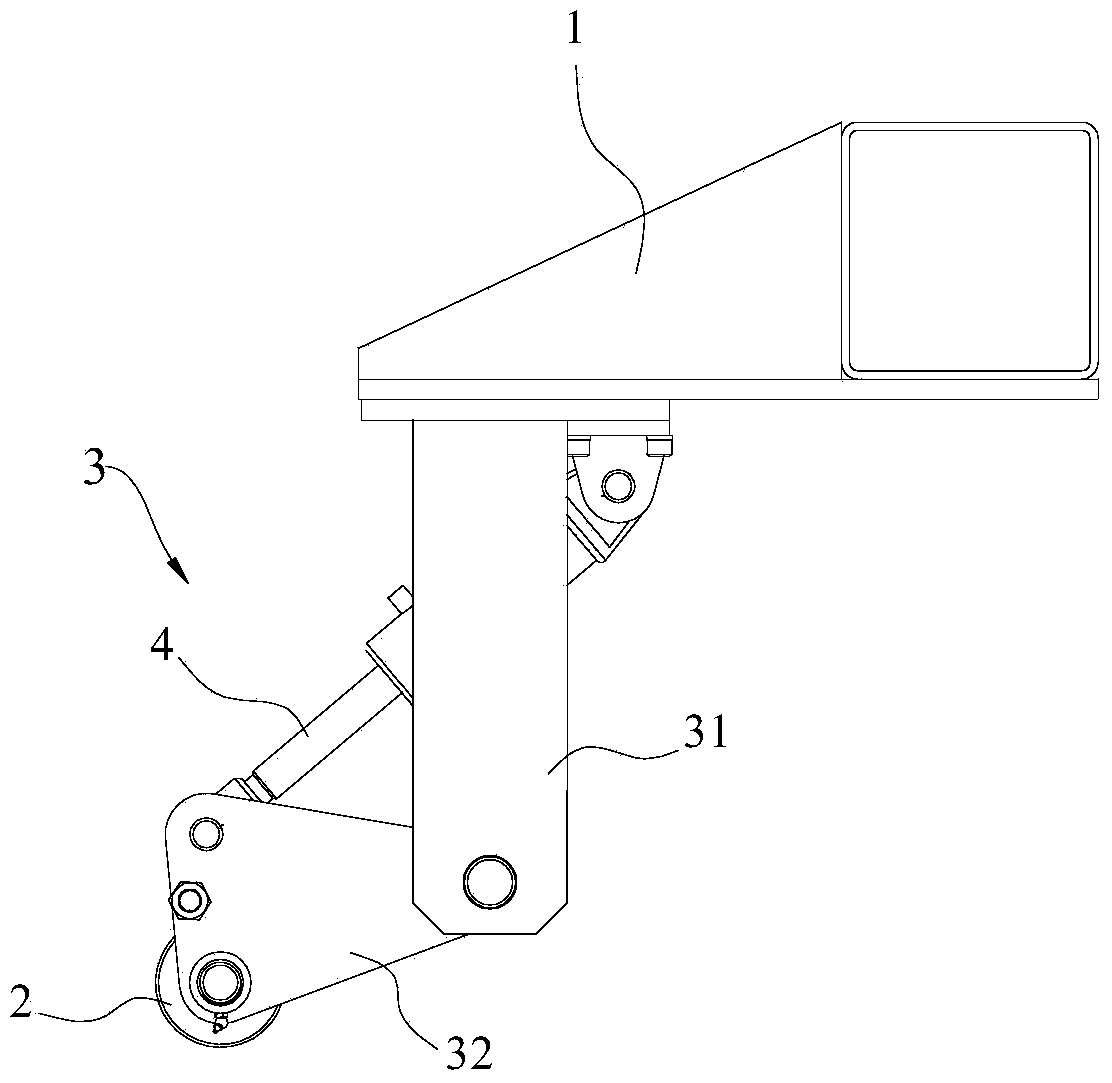

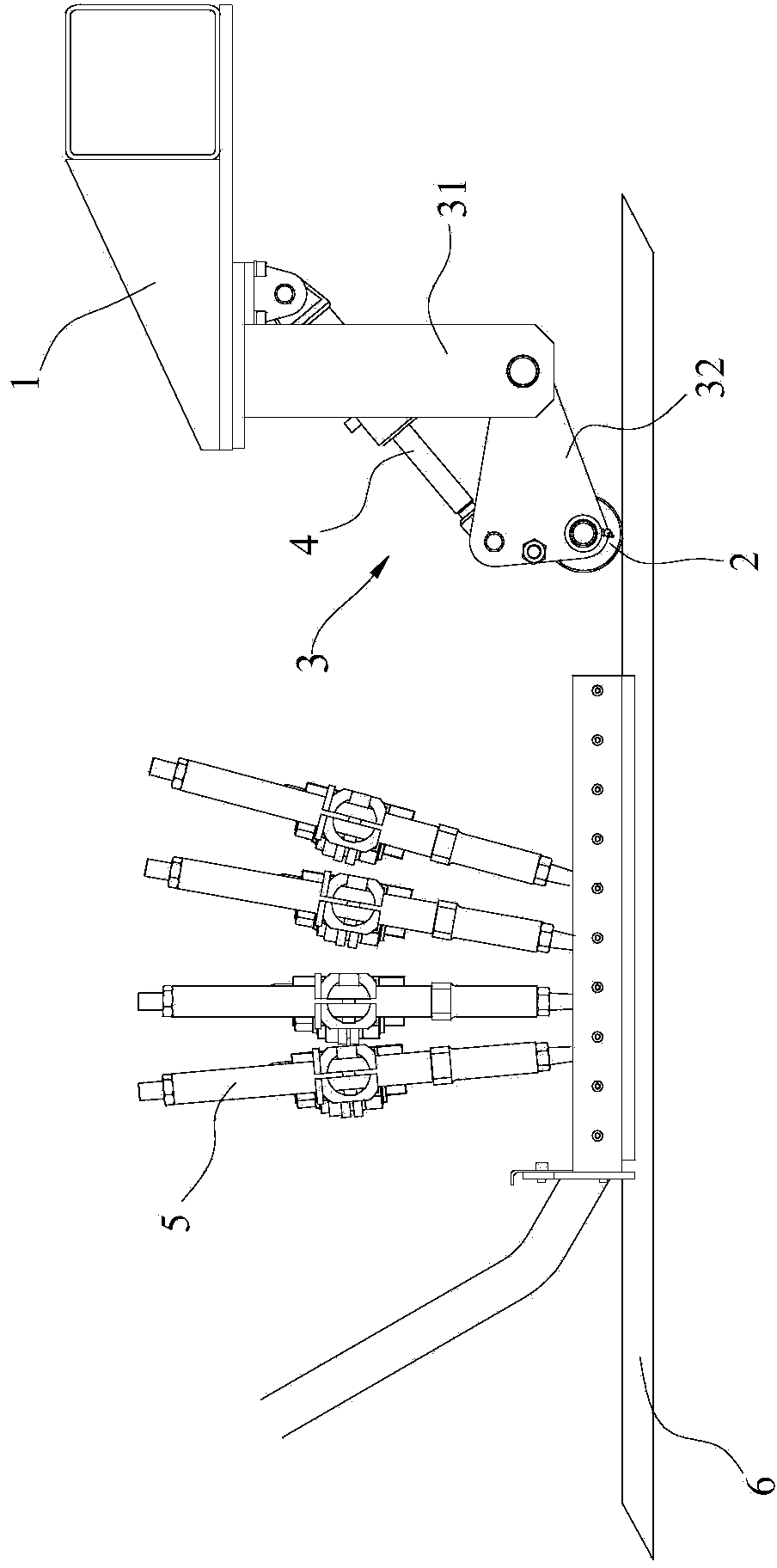

[0020] refer to figure 1 , figure 2 , The present invention provides a welding seam force application device, comprising a support arm 1 and a force application block 2 located below the support arm 1 , and a force application mechanism 3 for pressing the force application block 2 downward is provided on the support arm 1 .

[0021] As a preferred embodiment of the present invention, the force application block 2 is preferably a rolling wheel (of course, the force application block 2 can also be in the form of a compact), during the welding process of the internal and external welding of the submerged arc welded pipe 6, in the weld force application device The rolling wheel exerts pressure on the weld that is still in the liquid or semi-solid stage, so that the liquid or semi-solid weld is plastically deformed according to the surface shape of the rolling wheel, resulting in a liquid forging effect. After forging, the inside of the weld is uniform and dense. Eliminate possib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com