Novel tubular-structure electric unmanned helicopter

An unmanned helicopter and tube-type technology, which is applied to the fuselage, rotorcraft, motor vehicles, etc., can solve the problems of prolonging the sailing time of new energy batteries, and achieve the effects of saving production materials, prolonging sailing time, and simplifying the main structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The specific implementation manners, structures, features and functions provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

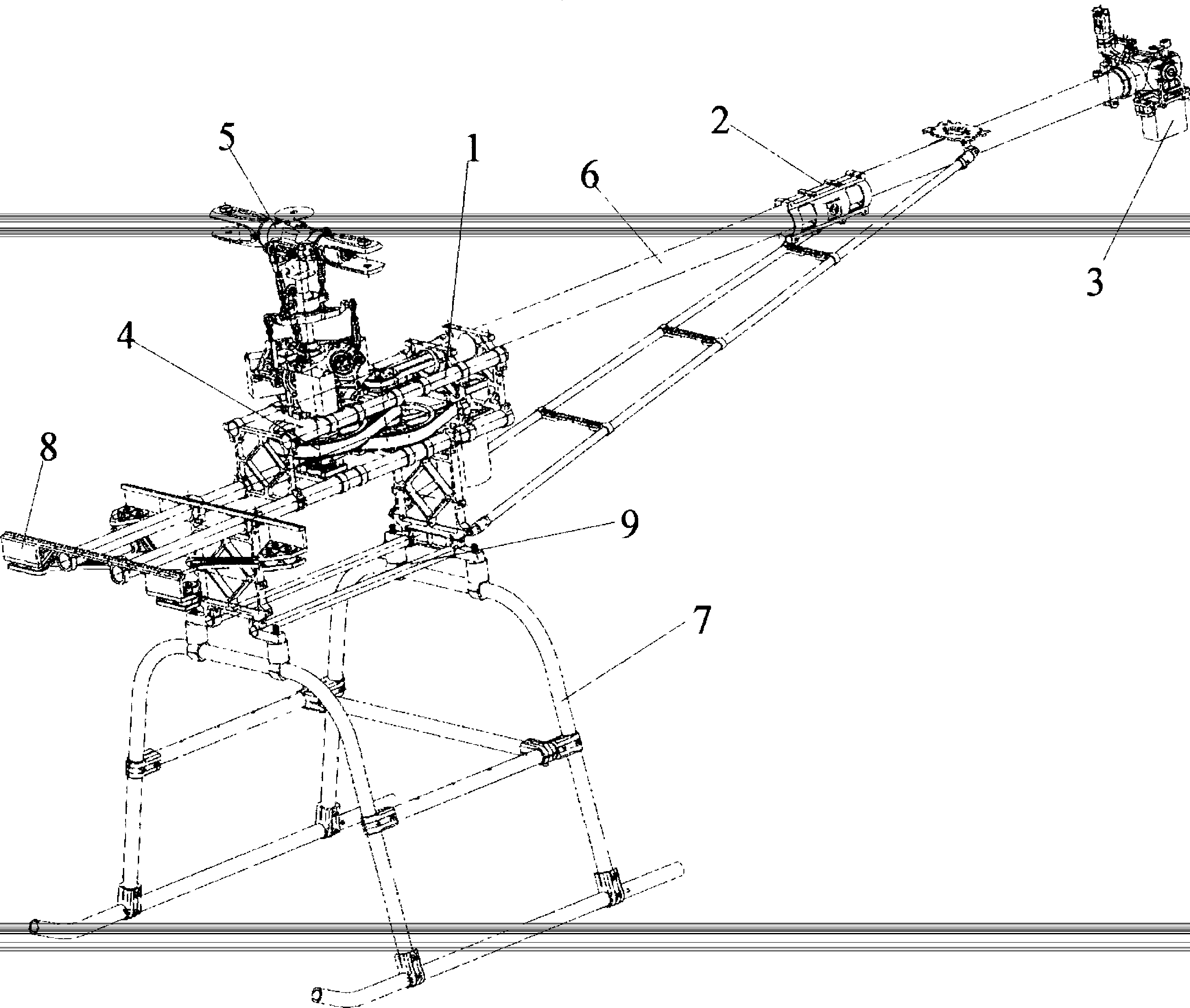

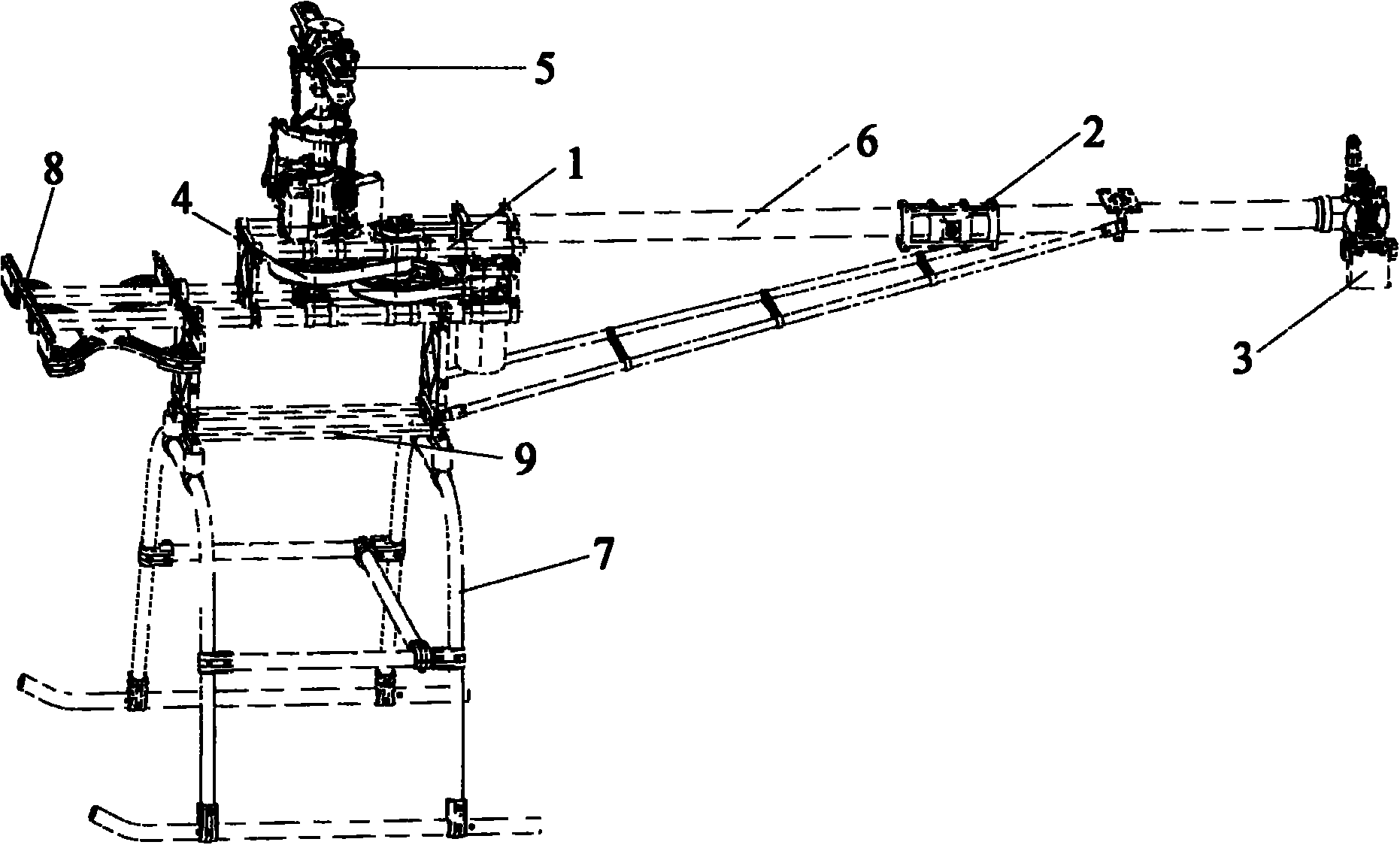

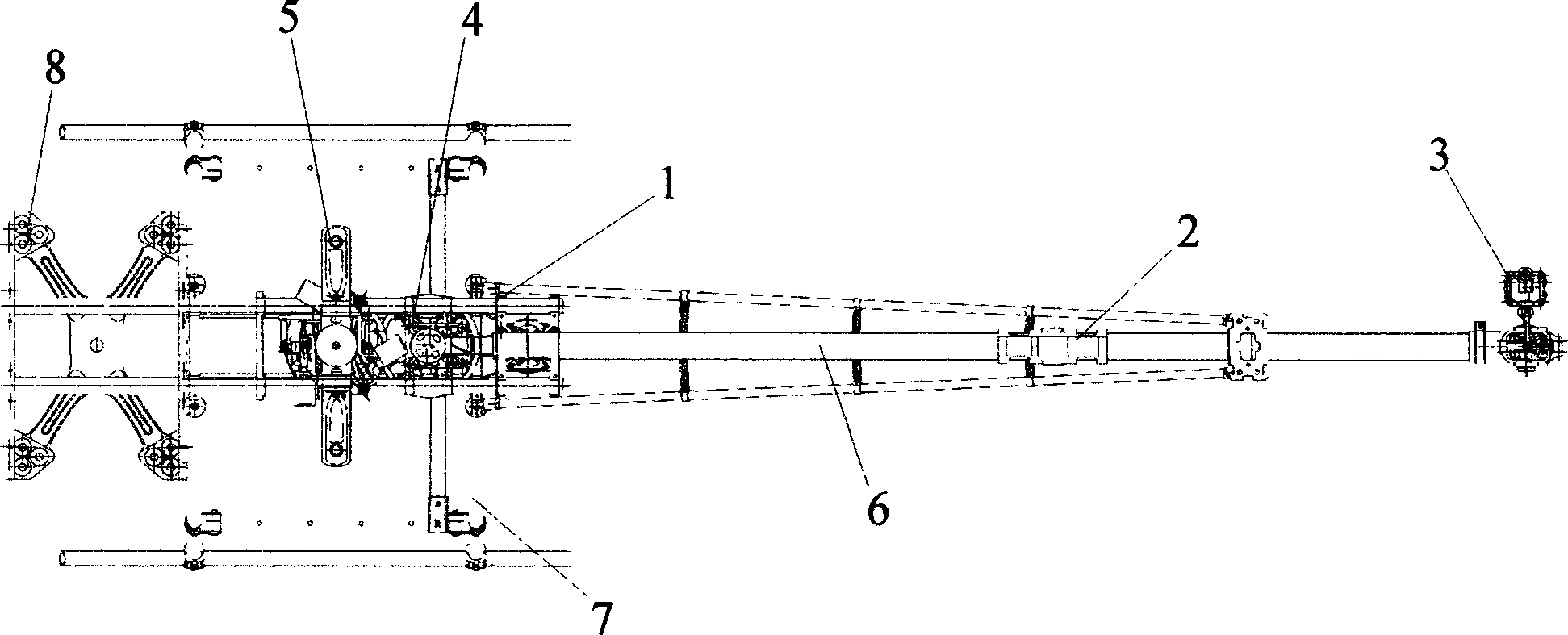

[0051] Example: such as Figure 1-3 As shown, an electric unmanned helicopter using new materials, low-cost, high-safety, and capable of carrying different equipment for operations with four-tube structure design; through the design of high transmission ratio and load ratio (4), plus The lithium polymer battery prolongs the sailing time of the new energy battery and can carry heavier operating equipment; the detachable device for the tail pipe (2), the shock absorption system for the tail servo (3), and the aileronless structure (5 ), all ensure the stability and safety of unmanned helicopter flight; the gimbal stabilization technology (8) ensures the shooting angle, and when shooting at high altitude, it can minimize the picture shake; realize the true sense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com