Reaction device and method for hydrogen production through photocatalytic water splitting

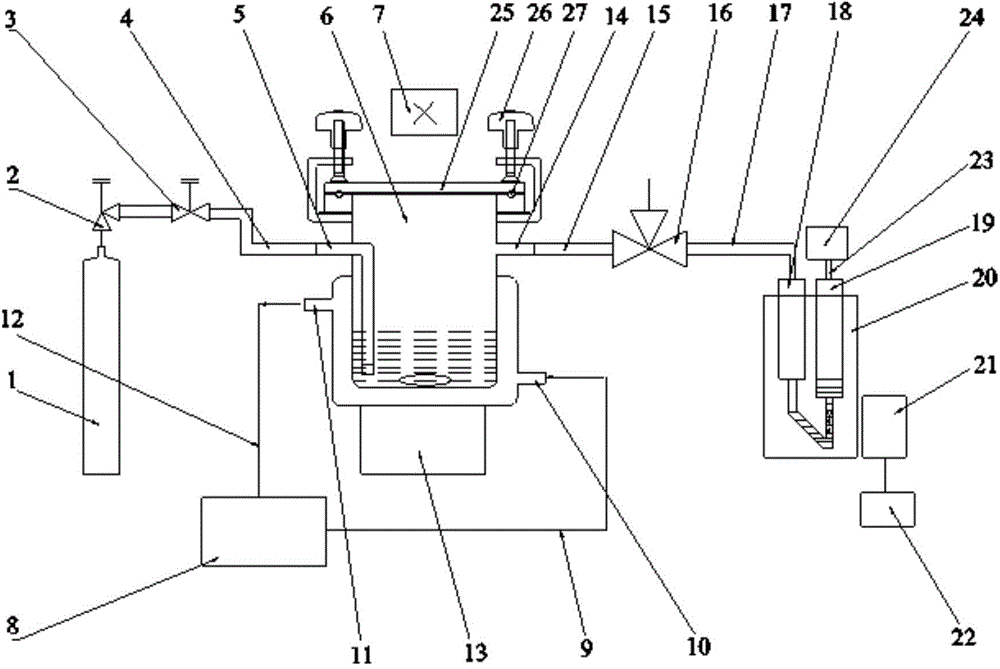

A technology of photo-splitting water for hydrogen production and reaction device, applied in hydrogen production and other directions, can solve the problems of poor gas circulation, high linear correlation requirements, low degree of automation, etc., and meet the requirements of convenient operation and maintenance, and air tightness. Low, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Step 1, in the reaction vessel of 400mL, add the Sr of 0.5g doping 1.6% (mass fraction) Cu 3 Ti 2 o 7 Catalyst (the catalyst is a titanium oxide catalyst), 92mL of distilled water and 10g of glycerol (the sacrificial agent is an organic alcohol sacrificial agent), and the total volume of the reaction liquid in the reaction vessel accounts for 1 / 4 of the volume of the reaction vessel;

[0049] Step 2, use an ultrasonic cleaner to perform ultrasonication for 1min, with an ultrasonic power of 80W, to disperse the catalyst;

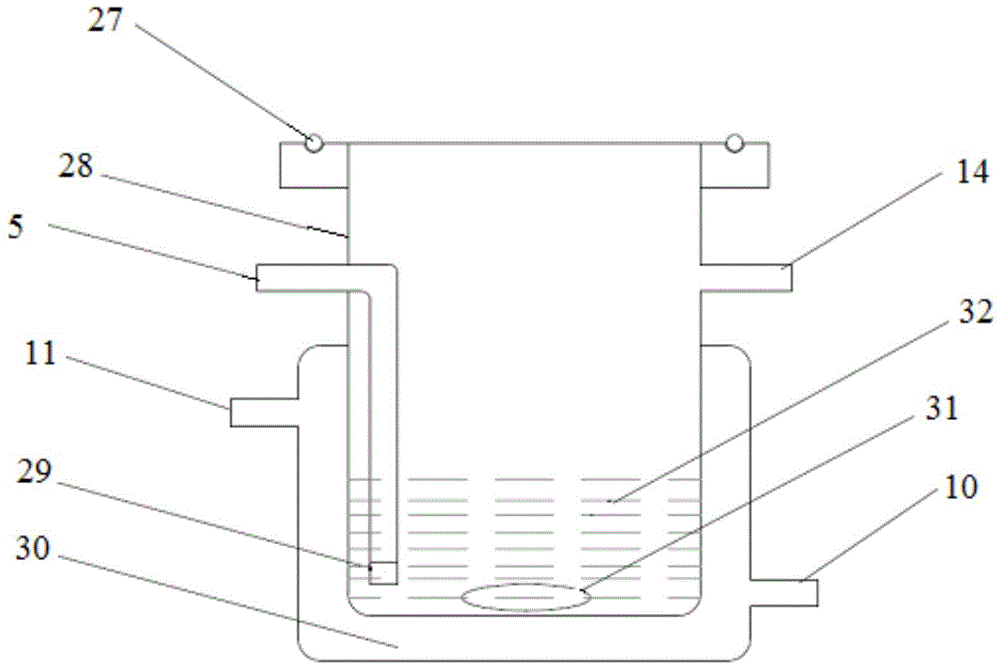

[0050] Step 3. Cover the quartz glass plate, clamp the reaction vessel, O-ring and quartz glass plate with 3 clamps on the side, and add cooling medium to the low temperature / constant temperature cooling circulating water machine to circulate the cooling medium into the jacket , the control temperature range is 20°C;

[0051] Step 4, select the light source as a high-pressure mercury lamp light source (300W), and adjust the distance between the ligh...

Embodiment 2

[0057] Step 1. Add 0.1g Pt / TiO to a 400mL reaction vessel 2 Catalyst (the catalyst is a titanium oxide catalyst), 100mL of water and 2g of formic acid sacrificial agent (the sacrificial agent is an organic acid sacrificial agent), and the total volume of the reaction liquid in the reaction vessel accounts for 1 / 4 of the volume of the reaction vessel;

[0058] Step 2, use an ultrasonic cleaner to perform ultrasonication for 2 minutes, with an ultrasonic power of 80W, to disperse the catalyst;

[0059] Step 3. Cover the quartz glass plate, clamp the reaction vessel, O-ring and quartz glass plate with 3 clamps on the side, add cooling medium to the low-temperature / constant-temperature cooling circulating water machine, and circulate the cooling medium into the jacket , the control temperature range is 25°C;

[0060] Step 4, select the light source as a xenon lamp light source (300W), and adjust the distance between the light source and the illuminated surface of the liquid in th...

Embodiment 3

[0066] Step 1, in the reaction vessel of 500mL, add 0.1g doping 1.8% (mol fraction) Cu, In-ZnSeS catalyst (catalyst is zinc sulfide catalyst), 150mL distilled water and 0.09mol triethylamine sacrifice agent (sacrifice agent is Organic amine sacrificial agent), the total volume of the reaction liquid in the reaction vessel accounts for 1 / 3 of the reaction vessel volume;

[0067] Step 2, use an ultrasonic cleaner to perform ultrasonication for 2 minutes, with an ultrasonic power of 80W, to disperse the catalyst;

[0068] Step 3. Cover the quartz glass plate, clamp the reaction vessel, O-ring and quartz glass plate with 4 clamps on the side, add cooling medium to the low temperature / constant temperature cooling circulating water machine, so that the cooling medium flows into the jacket , the control temperature range is 25°C;

[0069] Step 4, select the light source as a high-pressure mercury lamp light source (300W), and adjust the distance between the light source and the illu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com