A kind of silver nanoparticle composite bulk bismuthate glass material and preparation method thereof

A silver nanoparticle and bulk bismuthate technology, which is applied in the field of silver nanoparticle composite bulk bismuthate glass material and its preparation, can solve the problems of unanalyzed composite bulk material nonlinear effect and weak surface plasmon effect , to achieve the effect of wide infrared transmission range, excellent optical performance and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0018] The preparation method of the silver nanoparticle composite block bismuthate glass material of each embodiment comprises the following steps:

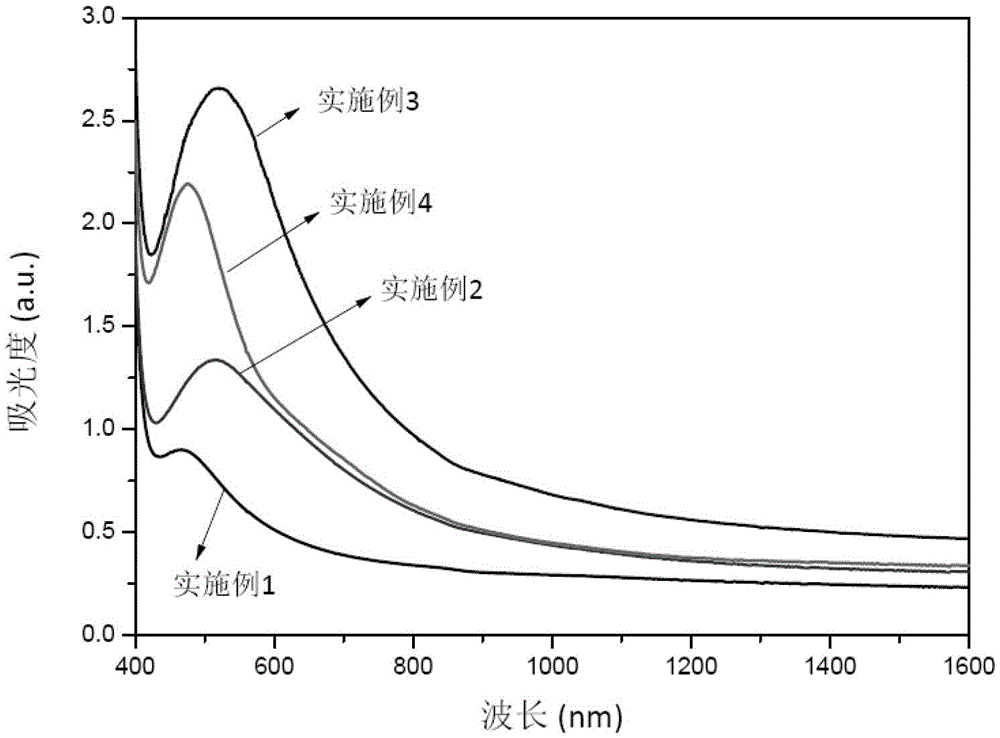

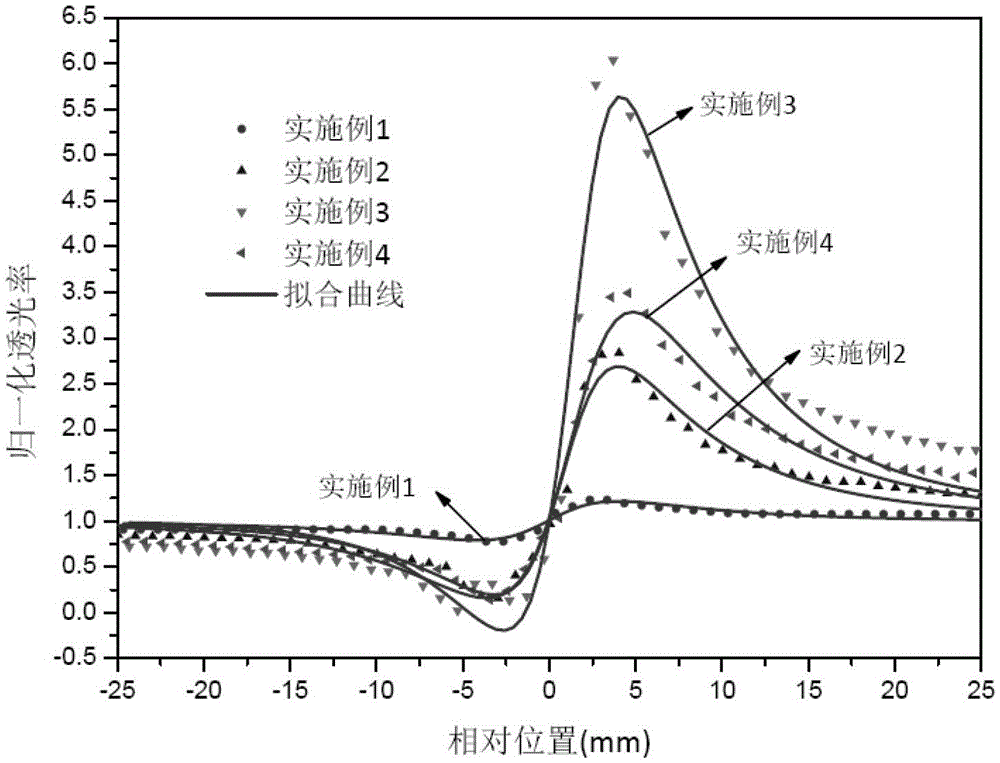

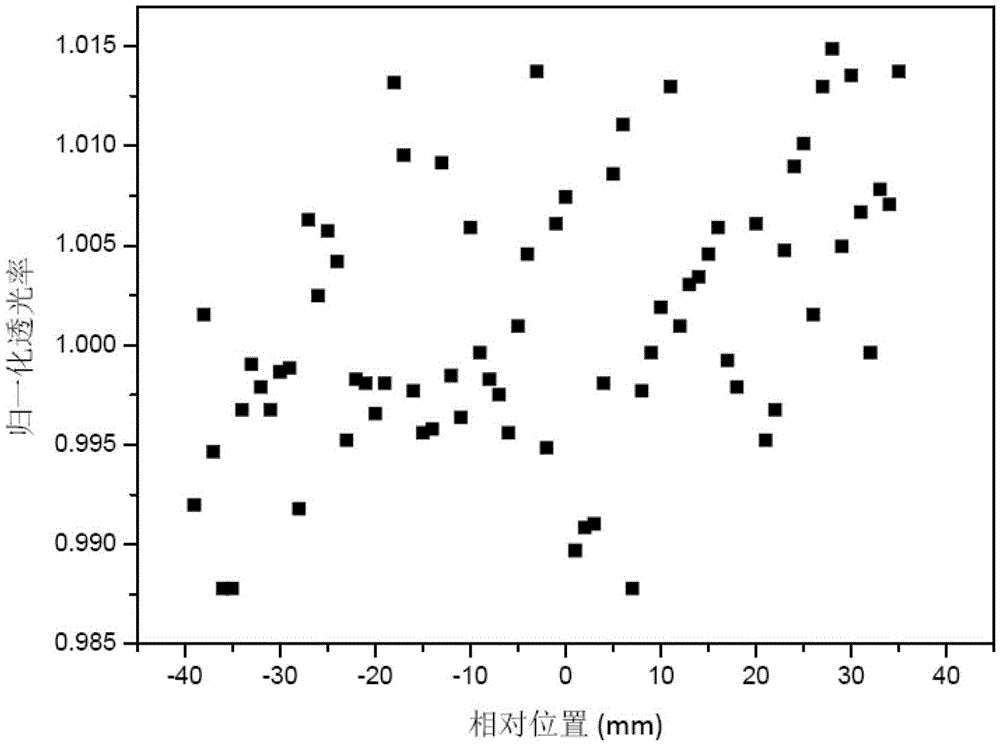

[0019] 1) Preparation of raw materials: Prepare various raw materials according to the ratio of raw materials and mix them evenly, among which, B 2 o 3 with H 3 BO 3 The form of introduction, the raw material and proportioning of embodiment 1~4 after conversion are shown in Table 1;

[0020] 2) Melting, quenching and annealing: Melt and stir the uniformly mixed raw materials at high temperature, the melting temperature is 1150-1200°C, and the melting time is 40-50 minutes, then pour the molten material into the preheated 150-250 ℃ to complete the quenching process, then put the mold into an annealing furnace to anneal the melt, the annealing temperature is 380-400 ℃, and the annealing time i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com