Fireproof heat-retaining plate for outer walls and production method thereof

A technology for a fireproof insulation board and a production method is applied in the field of external insulation and fireproof materials for external walls, and achieves the effects of simple production process, reduced loss and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

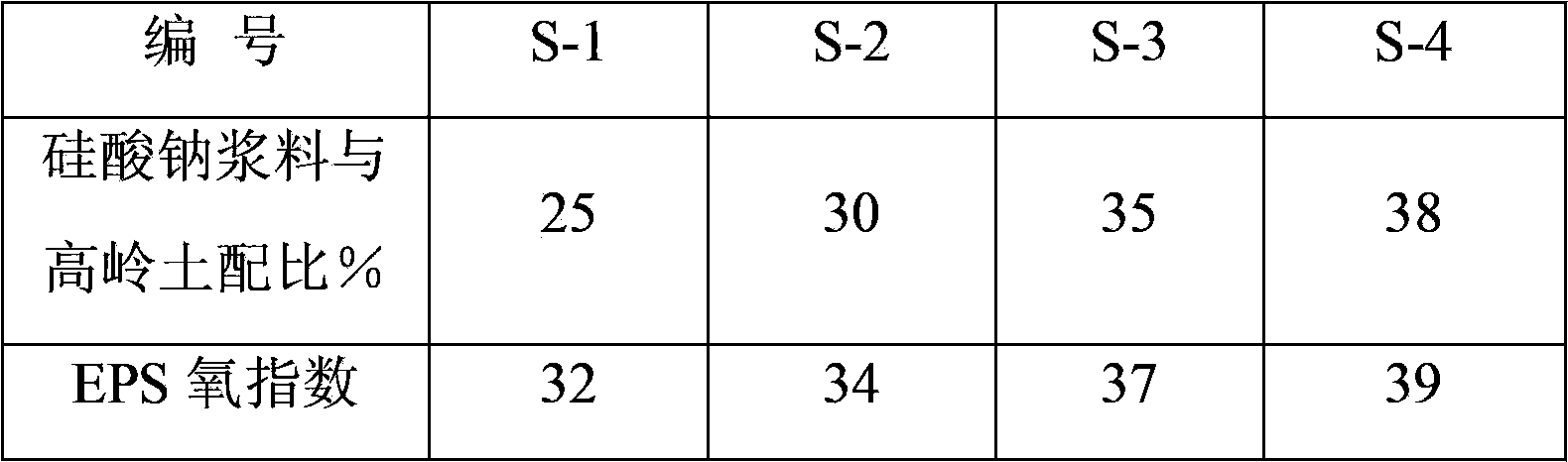

[0046] The specific steps are as follows: a. After foaming the expandable polystyrene (EPS) by steam to form 2-3mm particles, put it into the slurry which is adjusted to a liquid state by adding sodium silicate and water at a weight ratio of 1:5.5, and then Put 28% of the liquid weight of kaolin into the slurry and fully stir it into a slurry; then put the 2-3mm particles of foamed polystyrene (EPS) into the slurry after stirring, and put it into the fluidized bed at 47 degrees Heated, dried and dried to become a modified polystyrene (EPS) metering standby;

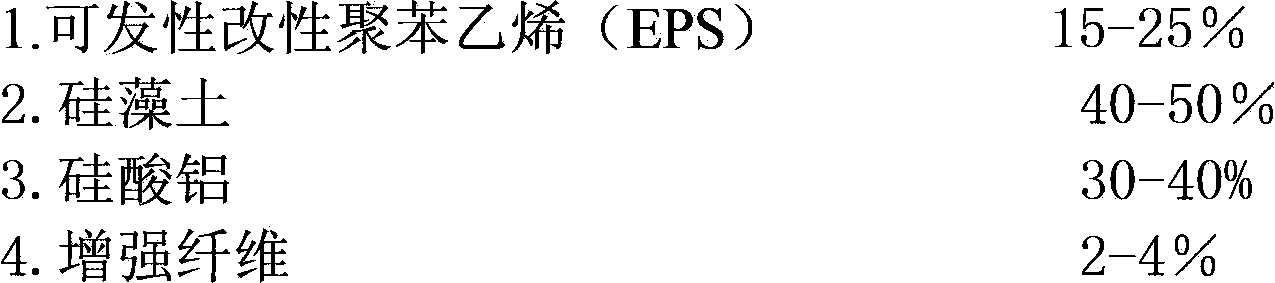

[0047] b. Measure other solid fillers and fully stir them with the modified EPS particles for later use. The stirring time for the solid fillers is 11 minutes. The specific weight percentage of the solid fillers is:

[0048]

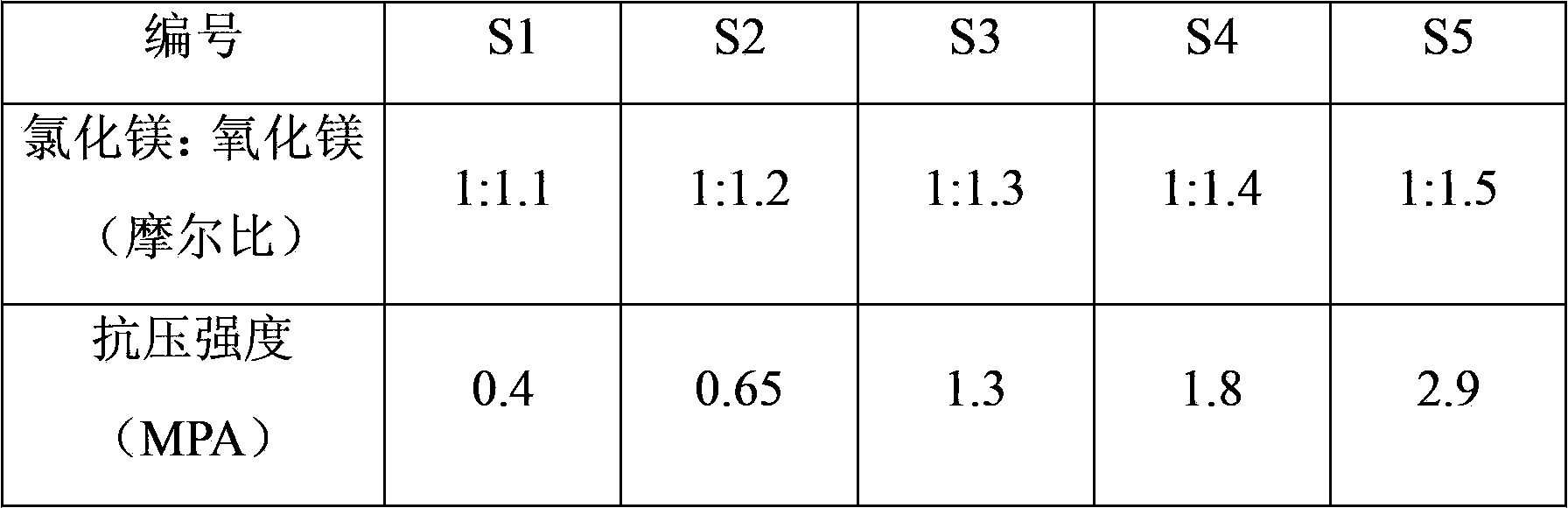

[0049] c. The preparation of the liquid slurry in the step is to use magnesium chloride:magnesium oxide (molar ratio) = 1:1.2, to prepare a magnesium chloride adhesive slurry and measure it, then...

Embodiment 2

[0052] The specific steps are as follows: a. After foaming the expandable polystyrene (EPS) by steam to form 2-3mm particles, put it into the slurry which is adjusted to a liquid state by adding sodium silicate and water at a weight ratio of 1:5.5, and then Put 38% of the liquid weight of kaolin into the slurry and fully stir it into a slurry; then put the 2-3mm particles of foamed polystyrene (EPS) into the slurry after stirring, and put it into the fluidized bed at 49 degrees Heated, dried and dried to become a modified polystyrene (EPS) metering standby;

[0053] b. Measure other solid fillers and fully stir them with the modified EPS particles for later use. The stirring time for the solid fillers is 15 minutes. The specific weight percentage of the solid fillers is:

[0054]

[0055] c. The preparation of the liquid slurry in the step is to use magnesium chloride: magnesium oxide (molar ratio) = 1:1.5, and then measure it after preparing a magnesium chloride adhesive s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com