Low-temperature-resistant oil-resistant low-smoke halogen-free flame-retardant polyolefin cable material

A technology of polyolefin cable material and low temperature resistance, which is applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems affecting the physical and mechanical properties and processing of cable materials, eliminate cracking problems, improve low temperature resistance, and improve The effect of oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

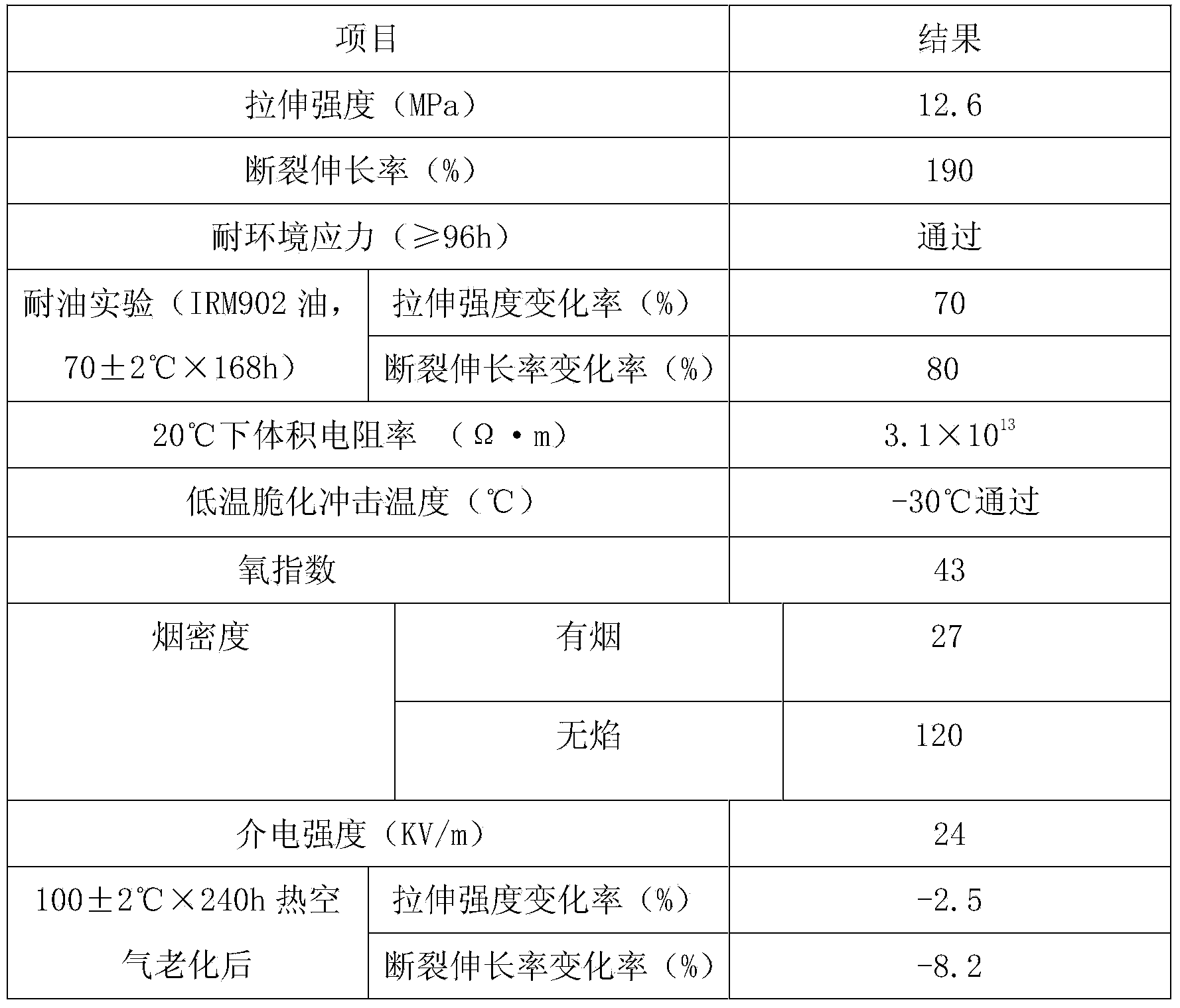

Examples

Embodiment Construction

[0013] A low-temperature, oil-resistant, low-smoke, halogen-free, and flame-retardant polyolefin cable material is prepared from the following component raw materials in weight (kg):

[0014] Metallocene linear low density polyethylene 40, POE: 25, maleic anhydride grafted polyethylene 8, low temperature resistant silicone rubber 15, N, N'-m-phenylene bismaleimide 2, aluminum hydroxide 55, three Molybdenum oxide 12, copper oxide 5, modified filler 8, nano silicon carbide 0.4, ferrocene 1, PE wax 1.5, 1,6 hexanediol diacrylate 2, antioxidant 10760.8, processing aid ACR0.2.

[0015] Wherein, the modified filler is prepared by the following method:

[0016] Calcinate the diatomite at 540°C for 3.5 hours, take it out, add 3% sodium hydroxide solution and grind it for 1.5 hours, then add 13% hydrochloric acid solution, adjust the pH value to 4-5, and age for 12 hours. Add sodium hydroxide solution to adjust the pH of the grinding liquid to be neutral, filter and dry to obtain fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com