Method for processing micro-pit arrays on metal surface

A micro-pit array, metal technology, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of complex processing links, high process costs, narrow application scope, etc., and achieves simple operation, low process cost, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

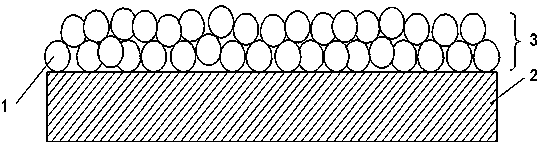

[0030] (a) Use a pipette gun to pipette 10ml of a suspension (10% by mass) containing polystyrene microparticles (spherical) with a particle size of 180±10nm into a beaker, and then measure 90ml of absolute ethanol into the same beaker middle. After the beaker was sealed, it was stirred ultrasonically for 60 minutes, and then mechanically stirred at high speed for 2 hours to prepare a polystyrene electrophoretic solution.

[0031] (b) Immerse the stainless steel sheet I (1 mm × 10 cm × 2 cm) after polishing, derusting, degreasing, etc. into the electrophoretic solution to a depth of 2 cm. Another stainless steel sheet II (1mm×10cm×2cm) that has been polished, derusted, degreased, etc. is also immersed in the electrophoretic solution. Then the stainless steel sheet I was used as the anode, and the stainless steel sheet II was used as the cathode, and a direct current of 5V was passed through for 1 minute. Because the polystyrene microparticles 1 are negatively charged, after ...

Embodiment 2

[0035] The step (a) of implementing the second example is the same as the step (a) of the first example. The remaining steps are as follows:

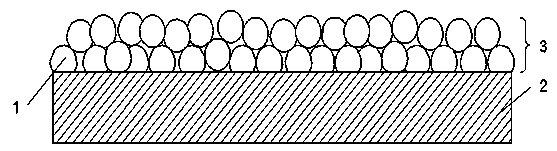

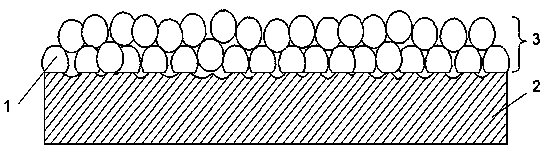

[0036] (b) Immerse the polished, derusted, degreased nickel sheet I (1mm x 10cm x 2cm) in the electrophoretic solution to a depth of 2cm. Put another nickel sheet II (1 mm × 10 cm × 2 cm) after polishing, derusting, degreasing, etc. into the electrophoretic solution. Then take the nickel sheet I as the anode and the nickel sheet II as the cathode, and pass a 5V direct current for 1 minute. Because the polystyrene microparticles 1 are negatively charged, after electrification, they will be electrophoretically deposited on the nickel sheet 1 to form a film 3 made of polystyrene microparticles 1.

[0037] (c) After natural drying, the nickel sheet I coated with polystyrene microparticles 1 was placed in an oven, baked at 75°C for 60 minutes, and then cooled to room temperature naturally. The glass transition temperature of the polystyre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com