Optical fiber and manufacturing method and identifying method of optical fiber

An optical fiber and color indicator technology, applied in clad optical fibers, glass optical fibers, optics, etc., can solve the problems of affecting optical fiber performance, optical fiber coating refractive index, complex optical fiber coating, environmental and human hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Preparation of optical fiber with inner coating containing chromogenic indicator:

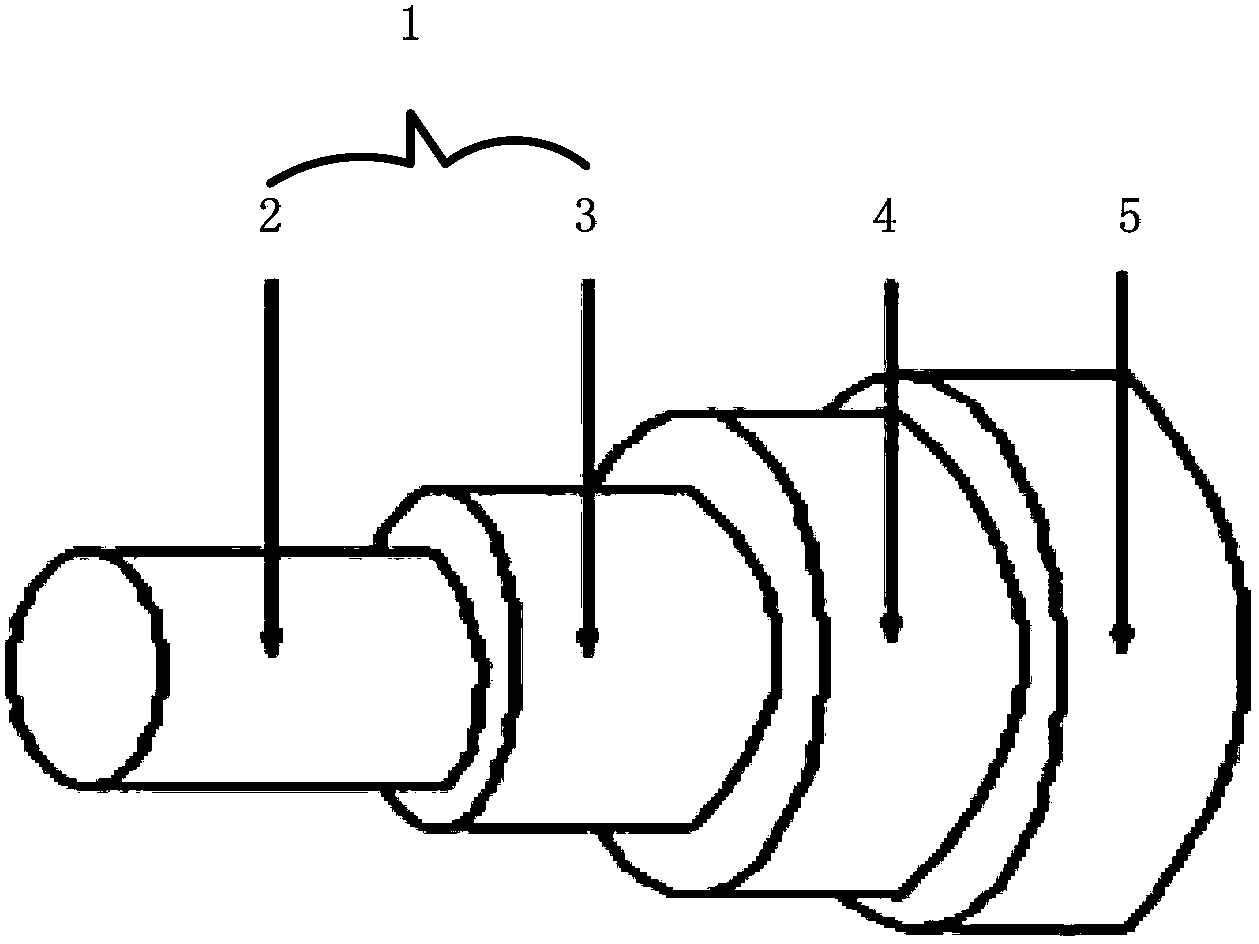

[0050] Adding phenolphthalein to the inner layer paint, the added mass of phenolphthalein is 0.0001% of the mass of the inner layer paint, stirring until the phenolphthalein is completely dissolved to obtain the inner layer paint containing phenolphthalein. Pass the inner coating containing phenolphthalein and the outer coating without any indicator through the fiber drawing tower at a certain diameter, speed and energy according to the figure 1 The structure is coated, drawn and solidified to form the optical fiber.

[0051] Methods for identifying optical fibers coated with chromogenic indicators:

[0052] Cut off 0.001g of optical fiber, and peel off the coating outside the core of this part of the optical fiber as the sample to be tested;

[0053] Mix and stir the sodium hydroxide aqueous solution with a mass concentration of 0.01% and methanol according to the volume ratio of 1:99...

example 2

[0056] Preparation of an optical fiber with an outer coating containing a chromogenic indicator:

[0057] Add phenolphthalein to the outer coating, the added mass of phenolphthalein is 10% of the mass of the outer coating, and stir until the phenolphthalein is completely dissolved to obtain the outer coating containing phenolphthalein. Pass the outer coating containing phenolphthalein and the inner coating without any indicator through the fiber drawing tower at a certain diameter, speed and energy according to the figure 1 The structure is coated, drawn and solidified to form the optical fiber.

[0058] Methods for identifying optical fibers coated with chromogenic indicators:

[0059] Cut off 1g of optical fiber, and peel off the coating outside the core of this part of the optical fiber as the sample to be tested;

[0060] The sodium hydroxide aqueous solution that mass concentration is 10% is standby as chromogenic solution;

[0061] Soak the sample to be tested in 10ml...

example 3

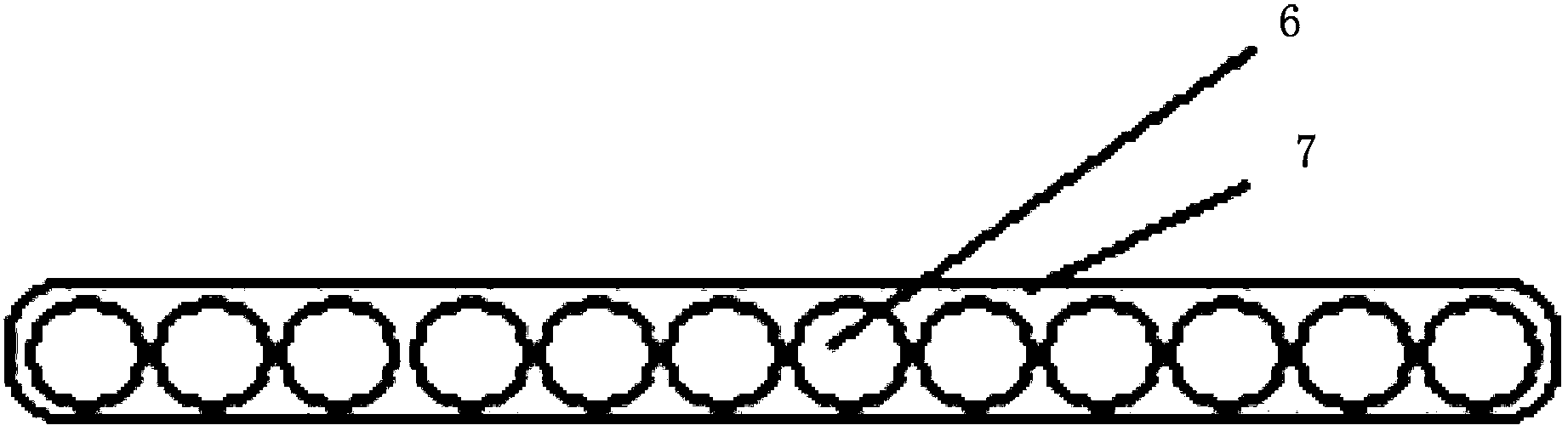

[0063] Prepare a ribbon-coated optical fiber containing a color indicator:

[0064] Adding phenolphthalein to the tape layer coating, the added mass of phenolphthalein is 0.01% of the mass of the tape layer coating, stirring until the phenolphthalein is completely dissolved to obtain the tape layer coating containing phenolphthalein. Pass the layered coating containing phenolphthalein through the fiber drawing tower at a certain diameter, speed and energy according to the figure 2 The structure is coated on the outside of the optical fiber 6, drawn and cured to form an optical fiber.

[0065] Methods for identifying optical fibers coated with chromogenic indicators:

[0066] Cut off 1g of the bundled optical fiber, and peel off the bundled coating of this part of the bundled fiber with a sharp knife as the sample to be tested;

[0067] Mix and stir the sodium hydroxide aqueous solution with a mass concentration of 0.1% and methanol according to the volume ratio of 1:1 and u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com