High-safety ultralong-life lithium ion battery, and positive pole material and formation method thereof

A lithium-ion battery and cathode material technology, which is applied in the design and manufacture of lithium-ion secondary batteries, can solve problems such as battery casing rupture, battery impedance increase, safety accidents, etc., and achieves suppression of gas production, reduction of gas production, High security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

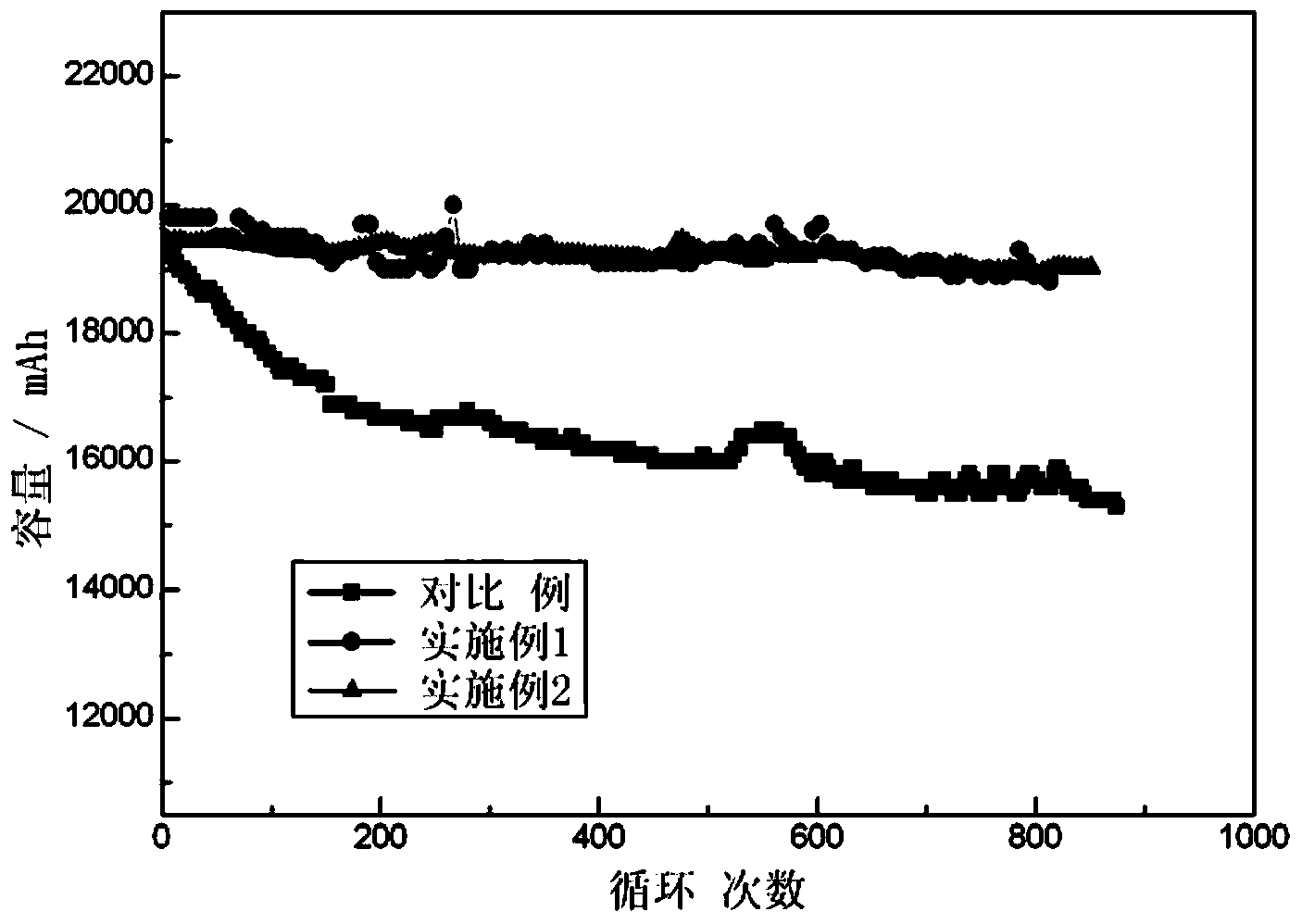

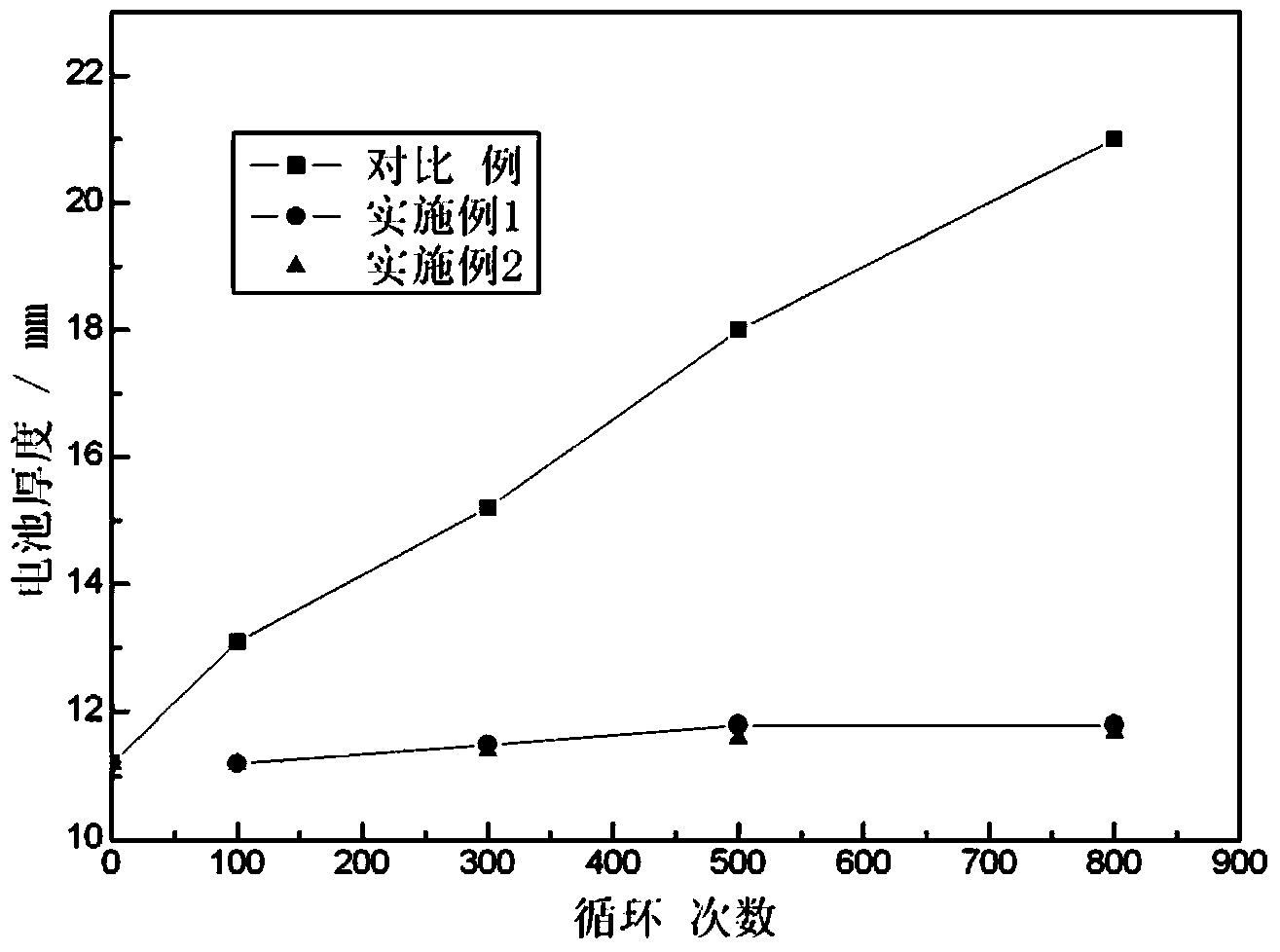

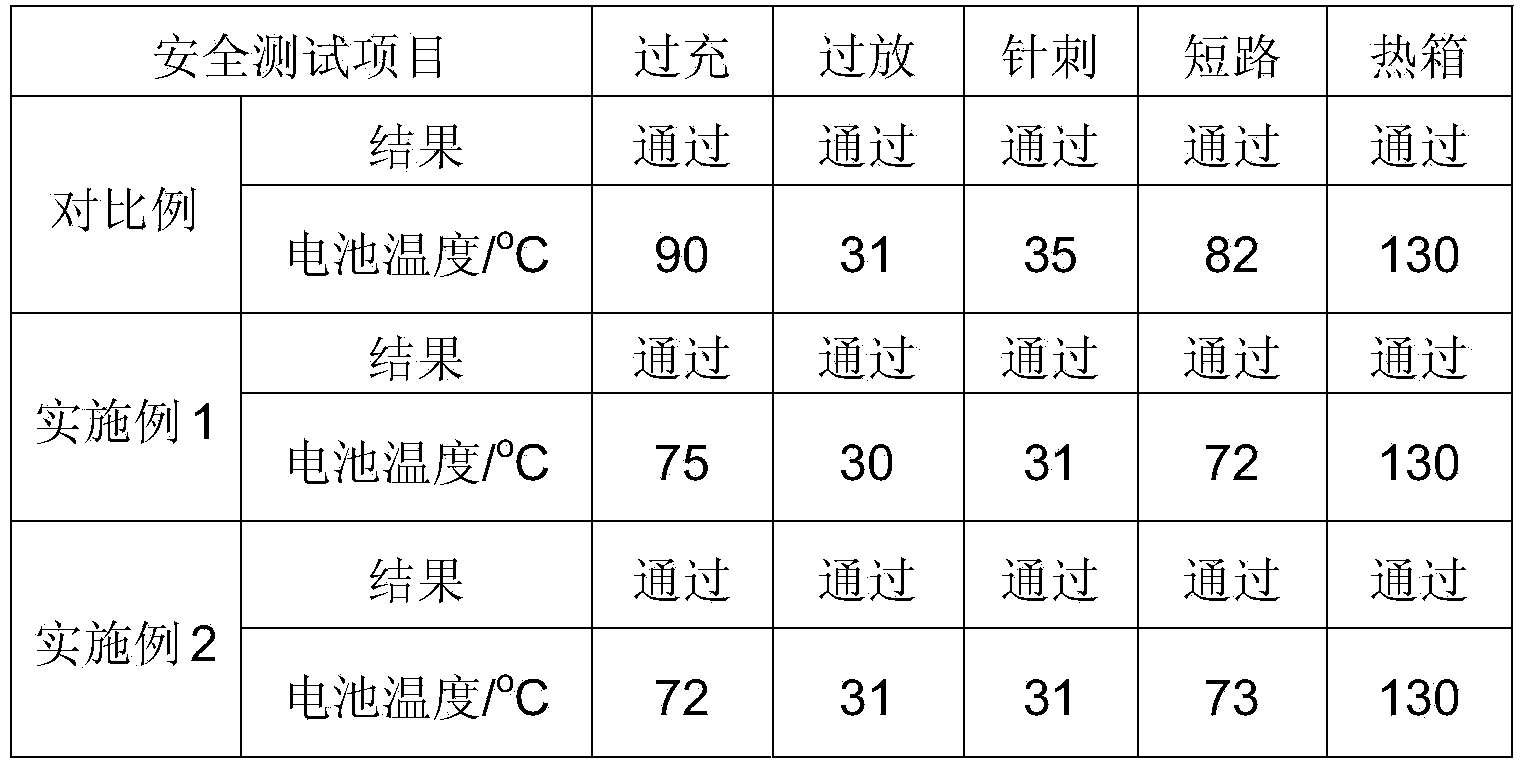

Embodiment 1

[0038] Nickel cobalt lithium manganese oxide LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 and alumina Al 2 o 3As the main and auxiliary additives respectively, lithium manganate and the main and auxiliary additives are mixed according to the ratio of 90%, 9% and 1% by mass to form the main active material, and the main active material is mixed with Supper P and polyvinylidene fluoride according to After mixing in a weight ratio of 92:4:4, dissolve it in N-methylpyrrolidone, stir evenly to make positive electrode slurry, and then perform coating, drying, rolling, and cutting according to the conventional lithium-ion battery manufacturing process. Form a positive electrode sheet; mix lithium titanate, Supper P, and polyvinylidene fluoride in a weight ratio of 92:4:4, dissolve in N-methylpyrrolidone, stir evenly to make a negative electrode slurry, and then use conventional lithium The ion battery manufacturing process is coated, dried, rolled, and cut to make negative electrodes; the positiv...

Embodiment 2

[0040] Nickel cobalt lithium manganese oxide LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Lithium manganate and calcium oxide CaO are used as the main and auxiliary additives respectively. Lithium manganate is mixed with the main and auxiliary additives according to the mass percentage of 90%, 8%, and 2% to form the main active material. The main active material is mixed with Supper P, poly Vinylidene fluoride is mixed according to the weight ratio of 92:4:4, dissolved in N-methylpyrrolidone, stirred evenly to make positive electrode slurry, and then coated, dried, and rolled according to the conventional lithium-ion battery manufacturing process , cutting to make a positive electrode sheet; mixing lithium titanate with Supper P and polyvinylidene fluoride in a weight ratio of 92:4:4, dissolving in N-methylpyrrolidone, stirring evenly to make a negative electrode slurry, and then According to the conventional lithium-ion battery manufacturing process, it is coated, dried, rolled, and cut to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com