Decarbonation process

A carbon dioxide and carbon dioxide removal technology, applied in new fields, can solve the problems of cumbersome installation and not very effective, and achieve the effect of flexibility advantage and excellent heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Description of the method

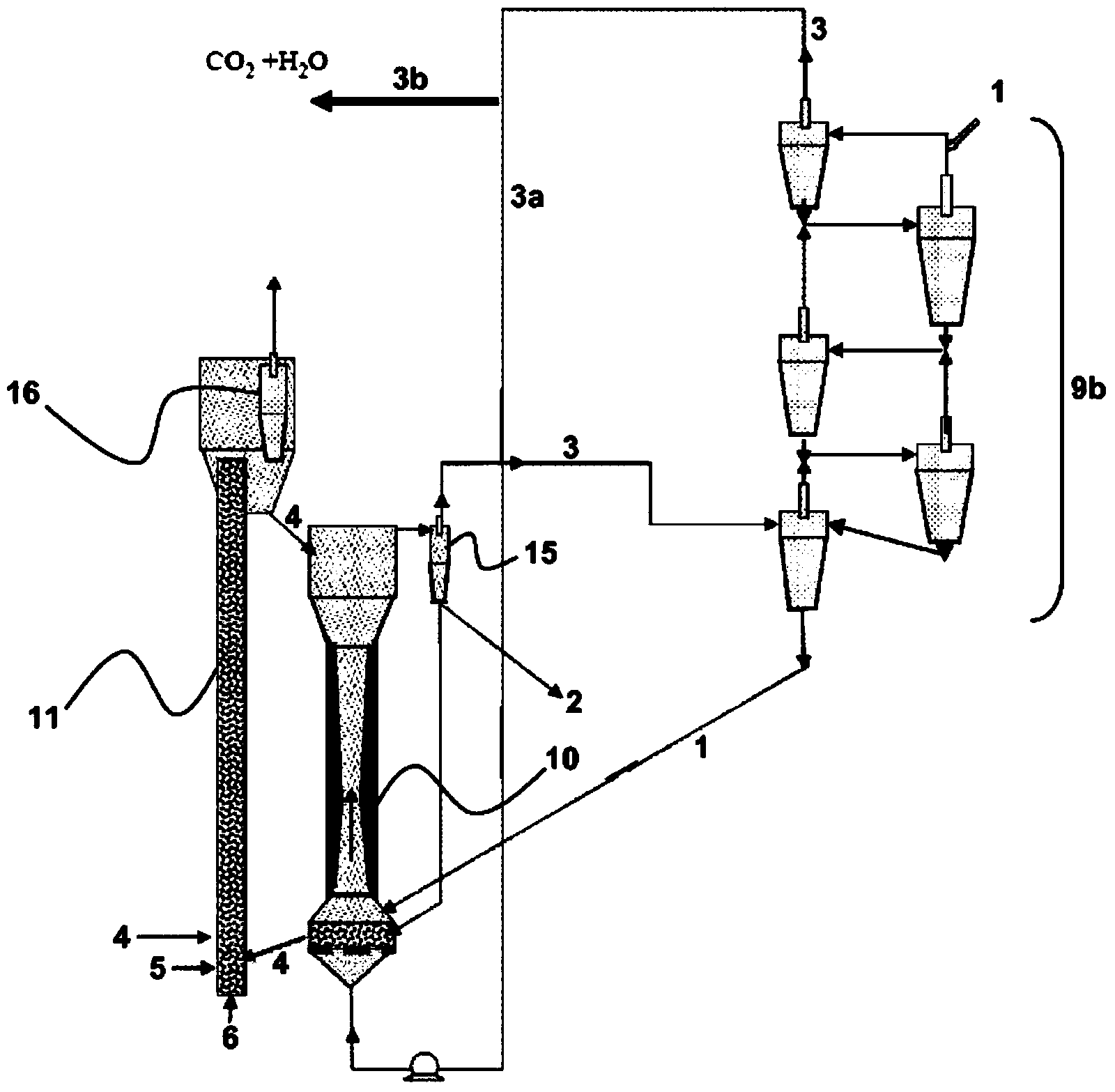

[0055] Due to the specificity of the clinker production method, the system proposed according to the invention for the concentration of carbon dioxide differs fundamentally from known methods. This is based on the finding that 820kg of CO2 are emitted per tonne of clinker produced, of which 535kg is mainly from the decarbonation of calcium carbonate and 285kg from the combustion of fuels such as coal. Decarbonation is a purely thermal phenomenon. A stream of nearly pure carbon dioxide can be produced by performing the calcination reaction in an enclosure where the calcium carbonate is calcined by indirect heating.

[0056] principle

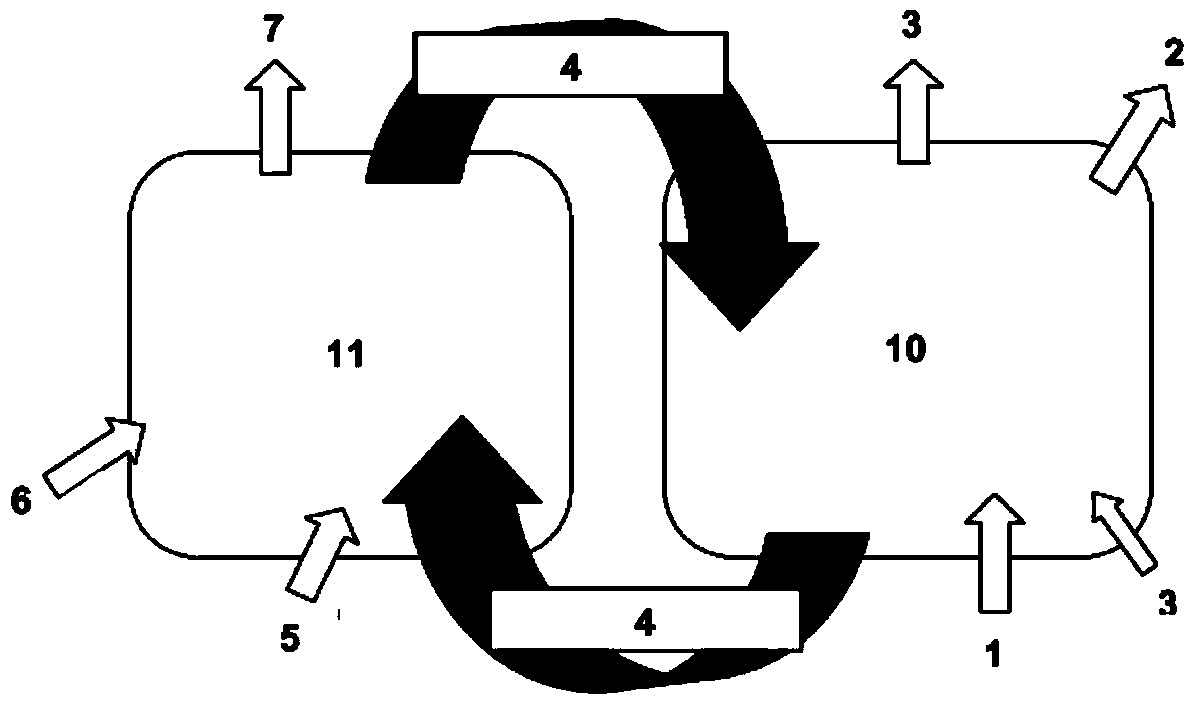

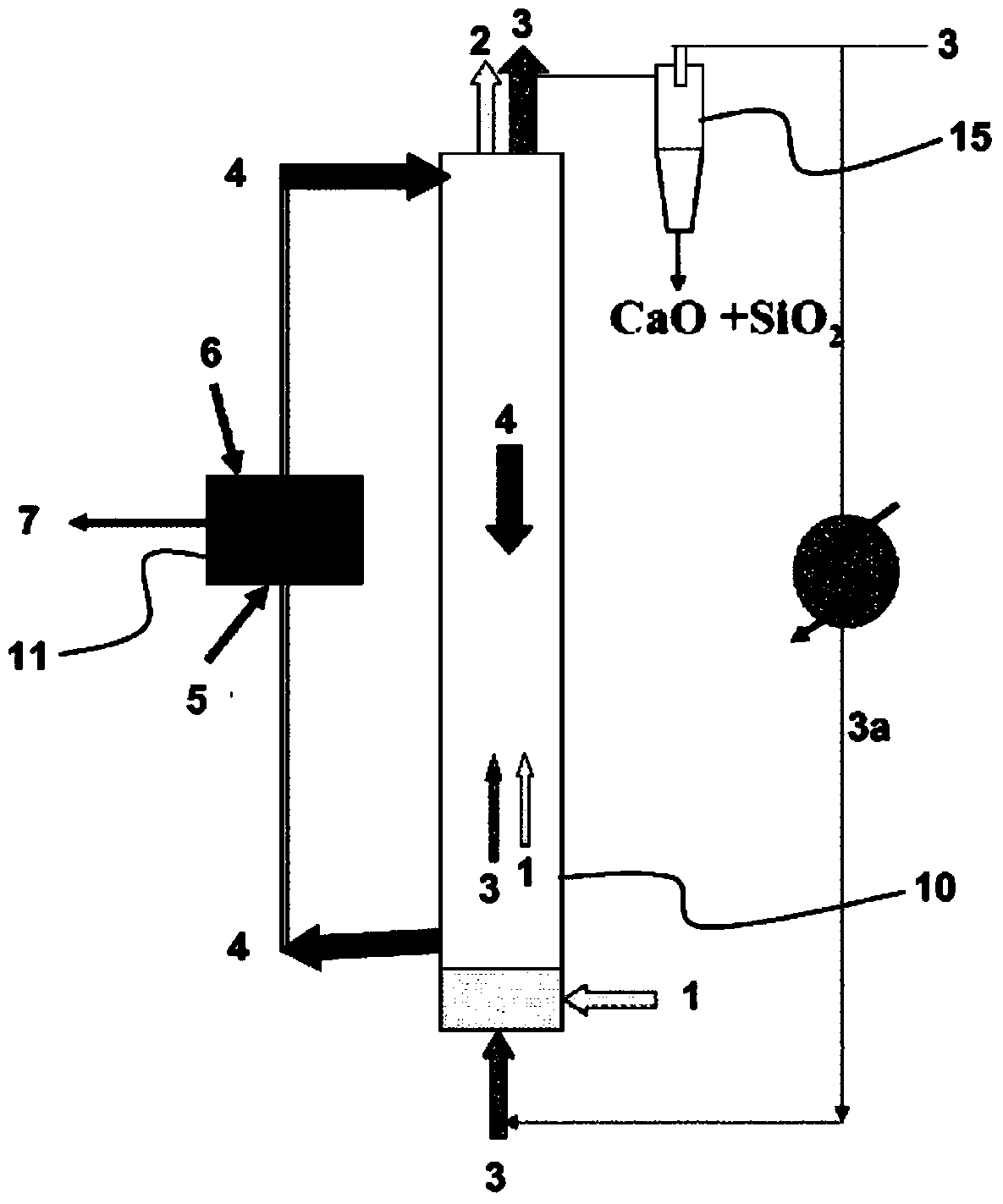

[0057] According to the method and apparatus of the present invention, such as figure 1 with figure 2 As shown, based on the use of a fluidized bed exchanger-reactor comprising two interacting parts: a "combustor" and a "calcinator".

[0058] Description of the calciner

[0059] The calciner is the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com