Chemical mutagenesis processing device for plant material

A plant material and chemical mutagenesis technology, which is applied in botany equipment and methods, plant gene improvement, plant phenotype improvement, etc., can solve the problem of treatment temperature, mutagen half-life not included, increasing test input costs, and affecting mutagenesis Effect and other issues, to achieve the effect of increasing mutagenesis efficiency, avoiding damage, and ensuring activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

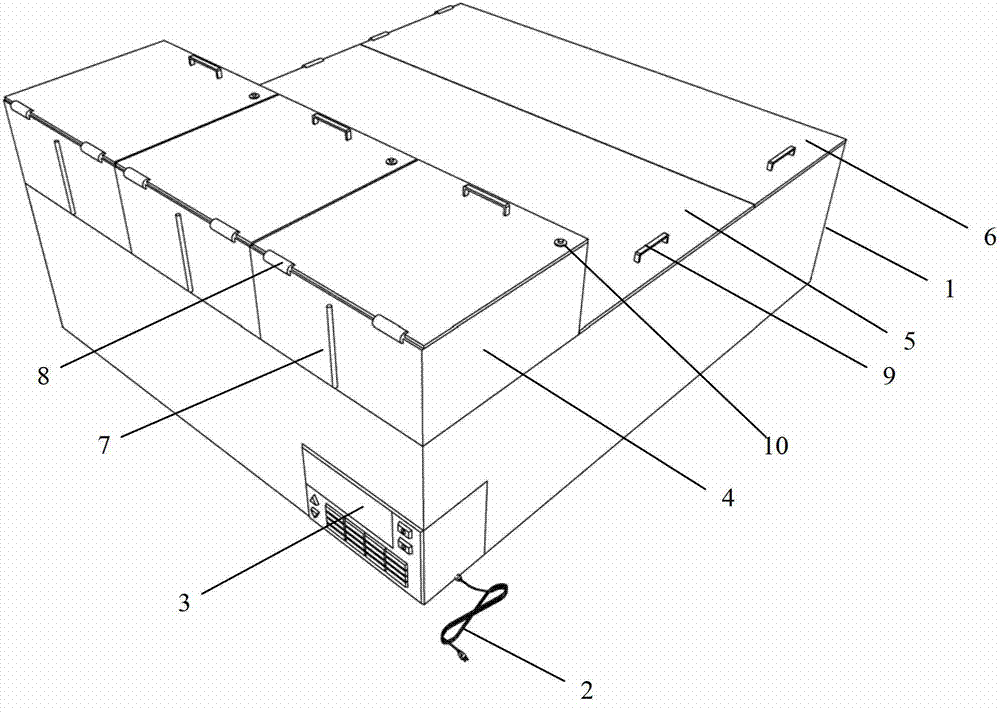

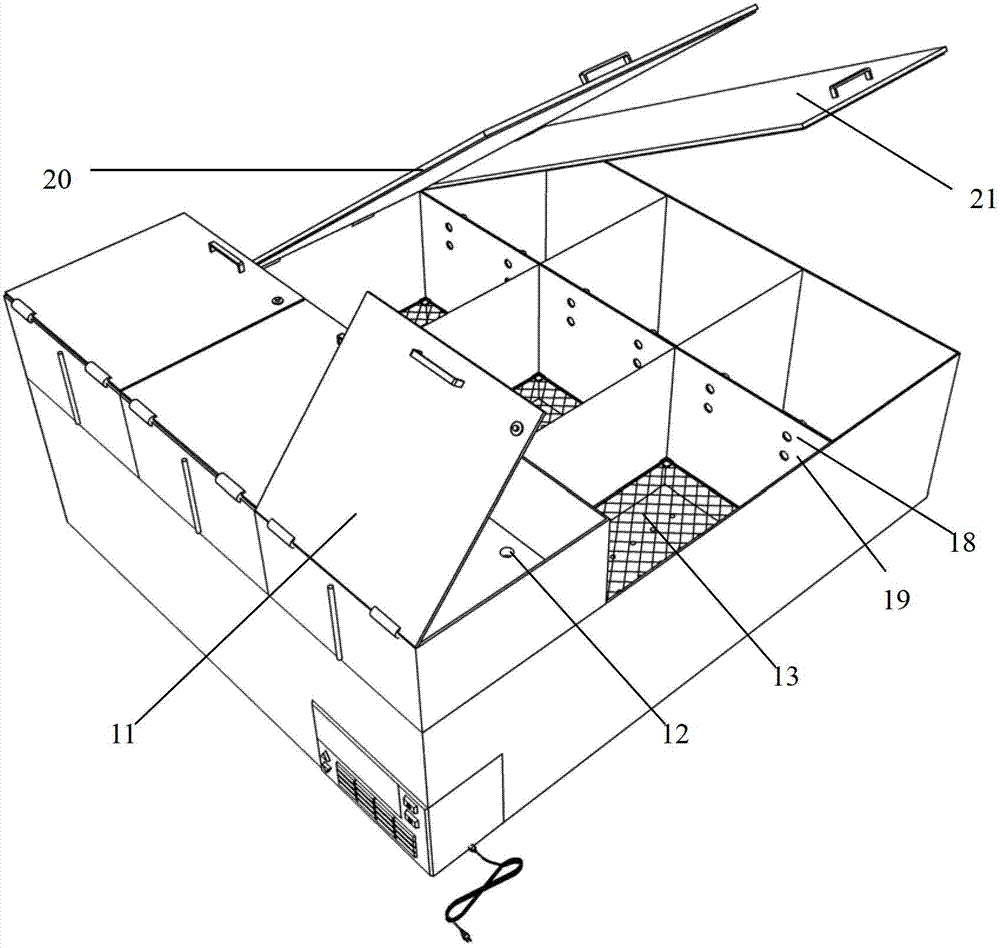

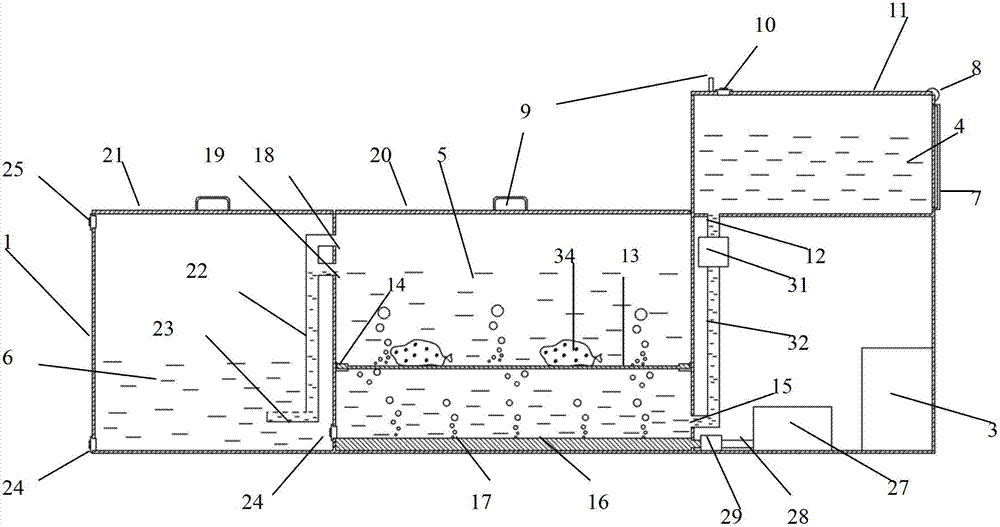

[0032] figure 1 It is a schematic diagram of the overall structure of the plant material chemical mutagenesis treatment device of the present invention; Figure 1a It is a schematic diagram of the overall structure when the cover plate on the plant material chemical mutagenesis treatment device of the present invention is opened; figure 2 is a cross-sectional view of a plant material chemical mutagenesis treatment device of the present invention; image 3 is a schematic diagram of a temperature-controlled heating plate of the present invention; Figure 4 is along image 3 The sectional view of line A—A in the center; Figure 5 is along image 3 The sectional view of the B-B line in the middle. like figure 1 A schematic diagram of the overall structure of the plant material chemical mutagenesis treatment device of the present invention; Figure 1a The overall structure schematic diagram when the cover plate on the plant material chemical mutagenesis treatment device of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com