Harmful gas vacuum adsorber

A vacuum adsorption and harmful gas technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of secondary pollution, limited adsorption capacity, inability to absorb toxic and harmful gases quickly and for a long time, and achieve purification. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

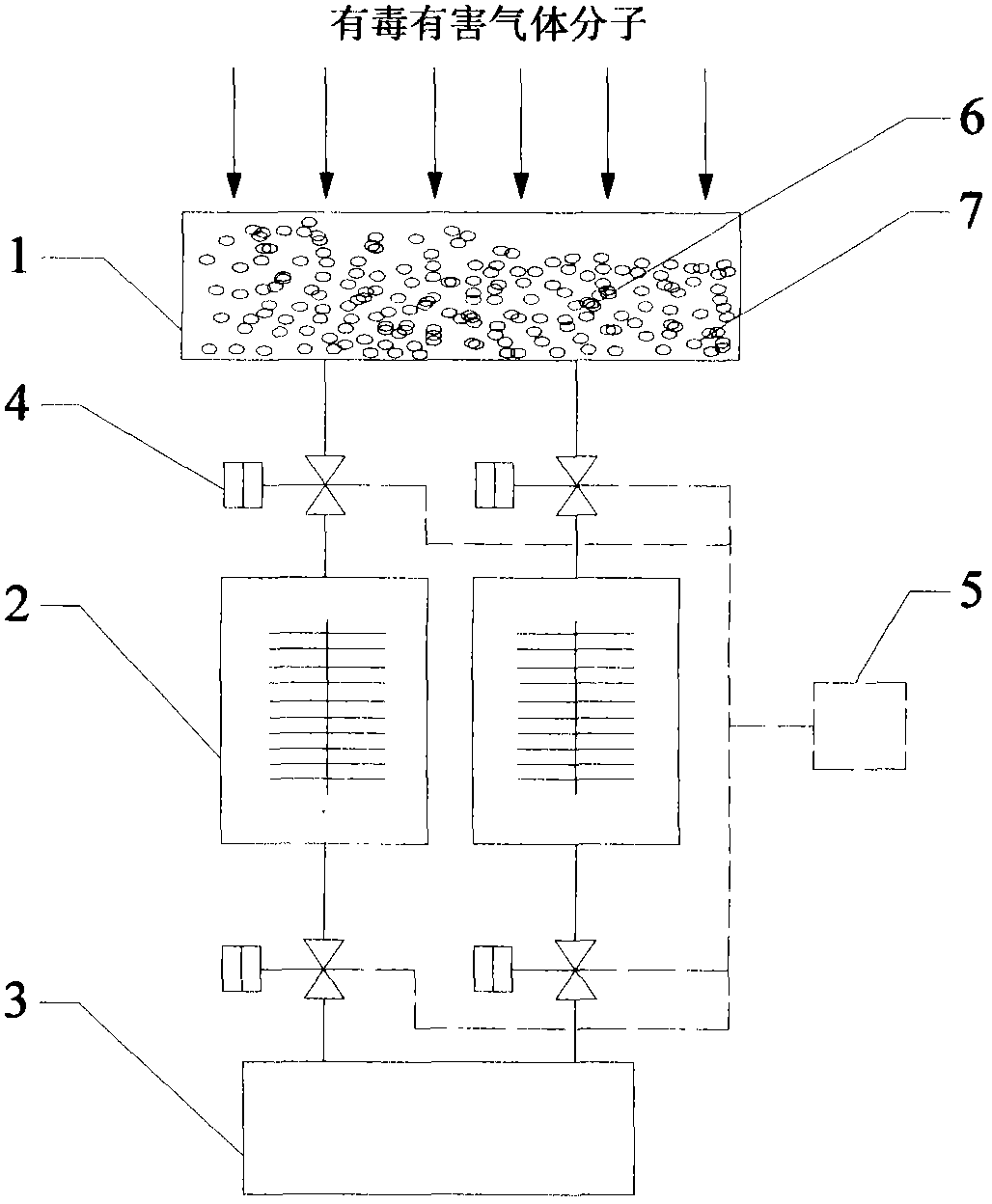

[0014] Such as figure 1 As shown, a harmful gas vacuum adsorption machine is composed of an adsorber 1, a solenoid valve 4, a buffer 2, a controller 5, and a vacuum pump 3. The adsorber 1, the buffer 2 and the vacuum pump 3 are connected sequentially through pipelines; a solenoid valve 4 is arranged between the connecting pipelines of the adsorber 1 and the buffer 2 and between the connecting pipelines of the buffer 2 and the vacuum pump 3, The solenoid valves 4 are connected to a controller 5, and the controller 5 is used to control the switches of the four solenoid valves 4. The buffer 2 is used to prevent the vacuum pump 3 from directly pumping atmospheric pressure, so as to prolong the service life of the vacuum pump 3 . Through the pumping of the vacuum pump 3, the gas circulation can be accelerated, so that the air flow quickly passes through the adsorber 1 and the buffer 2, and the adsorption speed is accelerated.

[0015] The adsorber 1 is filled with a filter 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com