Reflection-type roll wear degree on-line detection device

A detection device, reflective technology, applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of large environmental impact, poor anti-interference ability, etc., achieve high sensitivity, strong anti-electromagnetic interference ability, and easy operation flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

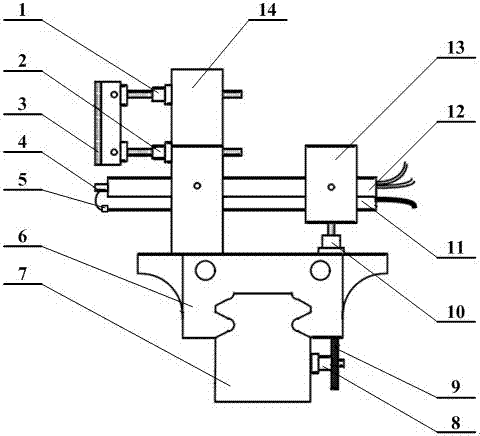

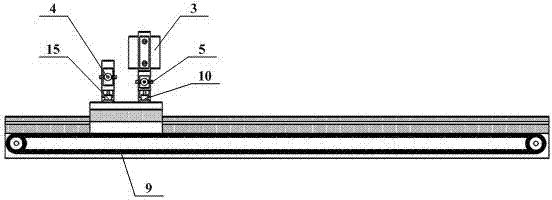

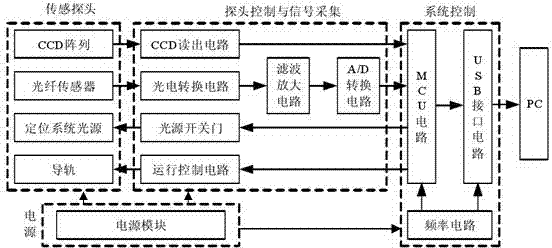

[0017] In the figure, the reflective roller wear on-line detection device includes linear stepper motor Ⅰ1, linear stepper motor Ⅱ2, CCD array 3, reflective fiber optic probe 4, laser light source 5, slider 6, linear guide rail 7, angle step Incoming motor 8, conveyor belt 9, linear stepping motor III10, electromagnetic displacement control tube I11, electromagnetic displacement control tube II12, support I13, support II14 and linear stepping motor IV15, the detection device is provided with a linear guide rail 7, a linear guide rail 7 The upper anastomotic slide is provided with a slider 6, and the electromagnetic displacement control tube I11 is connected to the slider 6 at two points, one of which is connected by a linear stepper motor III10, and the other connection point is fixed on the bracket I13; the electromagnetic displacement The control tube II12 is connected to the slider 6 with two points, one of which is connected through the linear stepper motor IV15, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com