Methyl acrylate metal salt-intercalated and modified kaolin as well as preparation method thereof

A technology of methacrylic acid and sodium methacrylate, applied in non-metallic elements, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as single function of kaolin and insignificant improvement of mechanical properties of rubber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

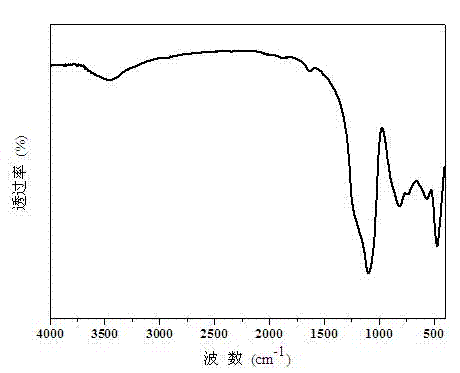

[0030] (1) Pretreatment of kaolin: Disperse 10 g of kaolin in 200 ml of N,N-dimethylformamide (DMF) solvent, and ultrasonicate at a constant temperature of 60°C for about 2 hours to obtain a milky white kaolin dispersion.

[0031] (2) Kaolin suspension: The kaolin dispersion obtained in step (1) was centrifuged at high speed, the DMF solvent was removed, and 9.60 g of white kaolin stable phase was obtained after vacuum drying for 12 hours; after that, the obtained kaolin was stabilized The phase was treated in a muffle furnace at 500°C for 2 h, and then the stable phase was dispersed in 100 ml of methanol, and ultrasonicated for 0.5 h to obtain a uniformly dispersed kaolin suspension.

[0032](3) Preparation of zinc methacrylate kaolin (ZDMA-Kaolin) by intercalation modification: first, zinc chloride was dissolved in distilled water to prepare a 620 mg / ml zinc chloride aqueous solution. Add 20ml of zinc chloride aqueous solution to the kaolin suspension obtained in the above s...

Embodiment 2

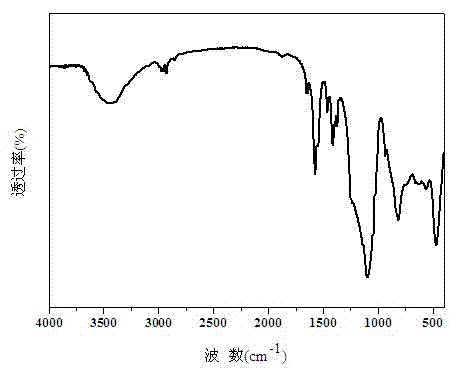

[0035] (1) Pretreatment of kaolin: Disperse 10 g of kaolin in 300 ml of N,N-dimethylformamide (DMF) solution, and ultrasonicate at 60°C for 2 hours to obtain a milky white kaolin dispersion.

[0036] (2) Kaolin suspension: The kaolin dispersion obtained in step (1) was centrifuged at high speed, the DMF solvent was removed, and 9.60 g of a white kaolin stable phase was obtained after vacuum drying for 12 hours. Afterwards, the obtained kaolin stable phase was placed in a muffle furnace at 500° C. for 3 h, and then the stable phase was dispersed in 100 ml of absolute ethanol, and ultrasonicated for 0.5 h to obtain a uniformly dispersed kaolin suspension.

[0037] (3) Preparation of zinc methacrylate functionalized kaolin by intercalation modification: first, zinc chloride was dissolved in distilled water to prepare a 544 mg / ml zinc chloride aqueous solution. Add 30ml of zinc chloride aqueous solution to the kaolin suspension obtained in the above step (2), and ultrasonicate for...

Embodiment 3

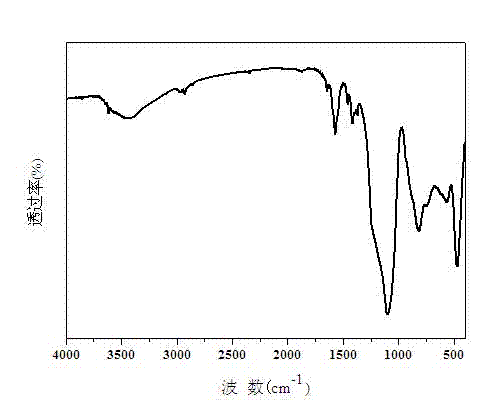

[0040] (1) Pretreatment of kaolin: Disperse 10g of kaolin in 200ml of N,N-dimethylformamide (DMF) solution, and ultrasonicate at a constant temperature of 60°C for about 2 hours to obtain a milky white kaolin dispersion.

[0041] (2) Kaolin suspension: The kaolin dispersion obtained in step (1) was centrifuged at high speed, the DMF solvent was removed, and 9.60 g of a white kaolin stable phase was obtained after vacuum drying for 12 hours. Afterwards, the obtained kaolin stable phase was placed in a muffle furnace at 500° C. for 3 h, and then the stable phase was dispersed in 100 ml of absolute ethanol, and ultrasonicated for 0.5 h to obtain a uniformly dispersed kaolin suspension.

[0042] (3) Preparation of magnesium methacrylate functionalized kaolin by intercalation modification: firstly, magnesium chloride was dissolved in distilled water to prepare a 365 mg / ml magnesium chloride aqueous solution. Add 40ml of magnesium chloride aqueous solution to the kaolin suspension o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com