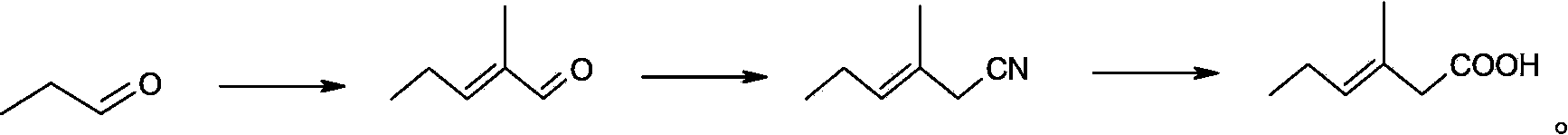

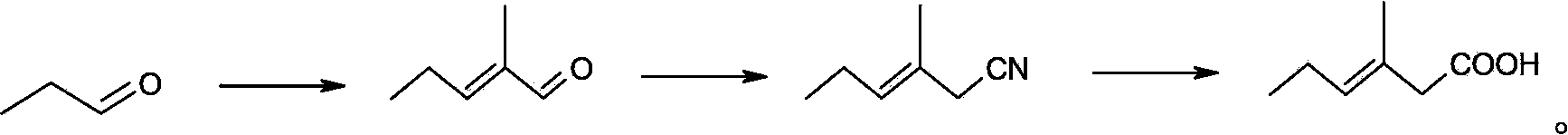

Synthesis method of 2-methyl-2-pentenoic acid

A synthesis method and technology of pentenoic acid, which are applied to the preparation of carbon-based compounds, chemical instruments and methods, and the preparation of carboxylic acid nitriles, can solve the problems of high raw material prices, easy deep oxidation, and difficult separation and purification, and achieve good aroma of the product , Simple operation, good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The synthesis of embodiment 1 2-methyl-2-pentenal

[0025] Add 10 grams of ammonium acetate and 30 grams of cyclohexane into a 500ml three-necked reaction flask, raise the temperature to 40 degrees and start to add 300 grams of n-propionaldehyde dropwise. The dropping time is 3 hours. , then reclaim solvent cyclohexane, distill to obtain 202 grams of 2-methyl-2-pentenal, yield 80%;

Embodiment 2

[0026] The synthesis of embodiment 2 2-methyl-2-pentenal

[0027] Add 10 grams of pyridine and 30 grams of cyclohexane into a 500ml three-necked reaction flask, raise the temperature to 40 degrees, and start to add 300 grams of n-propanal dropwise. The addition time is 3 hours. Then reclaim solvent cyclohexane, distill to obtain 215 grams of 2-methyl-2-pentenal, yield 85%;

Embodiment 3

[0028] Example 3 Synthesis of 2-methyl-2-pentenaldoxime

[0029] Add 100 grams of 2-methyl-2-pentenal, 130 grams of hydroxylamine sulfate and 300 grams of water into a 1000ml three-necked reaction flask, control the temperature at 10-15 degrees and start adding 120 grams of 50% sodium hydroxide solution dropwise, drop Add for about 3-5 hours, keep the temperature for 30 minutes after the dropwise addition, and then add 100 grams of mesitylene for extraction to obtain 208 grams of 2-methyl-2-pentenal mesitylene solution, with a yield of 93%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com