Ionic metal ink for ink-jet printing preparation of copper circuit graphs on printed board surface and its preparation method and printing method

A circuit pattern, metal ink technology, applied in the direction of copy/marking method, printing, ink, etc., can solve the problems of poor stability, easy oxidation and agglomeration, and achieve good catalysis, good adhesion and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

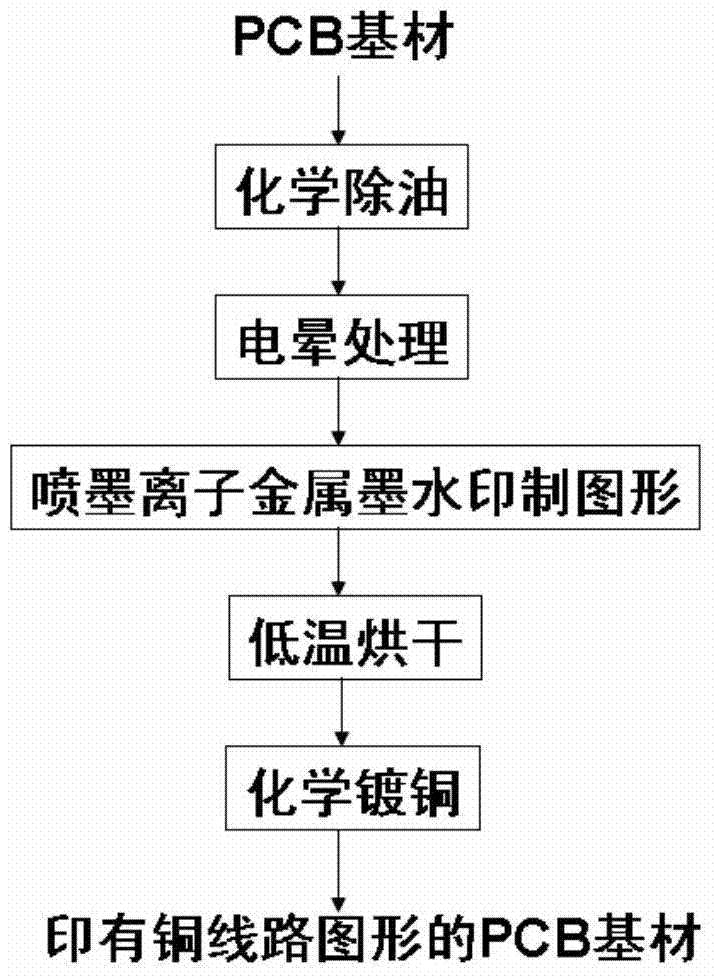

Method used

Image

Examples

specific Embodiment approach 1

[0038] Specific embodiment one: a kind of ionic metal ink used for inkjet printing copper circuit patterns on the surface of printed boards according to the present embodiment consists of 0.5-20 parts of bio-adhesive monomer, 0.01-5 parts After mixed reaction of metal salt, 3-10 parts of metal complexing agent, 55-95 parts of deionized water and 0.5-5 parts of pH buffering agent, 0.1-1 part of surface tension regulator, 0.1-4 parts The viscosity regulator adjusts the surface tension and viscosity of the ink, and finally adjusts the pH of the solution to 4-6 with a pH regulator; the bio-binder monomers are dopamine hydrochloride, norepinephrine, 5-hydroxydopamine, One or a combination of cidopa, α-methyldopamine, dexdopa, levodopa, α-methyldopa and nitrodopamine.

[0039] The bio-adhesive monomers in this embodiment all have a catechol structure, and are catalyzed by metal ions to be oxidized to generate a bio-adhesive under acidic conditions. When the biobinder monomers are a...

specific Embodiment approach 2

[0040] Embodiment 2: This embodiment differs from Embodiment 1 in that the pH buffer in the ionic metal ink is potassium hydrogen phthalate or sodium dihydrogen phosphate. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0041] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the viscosity regulator in the ionic metal ink is one of terpineol, methyl nylon acid or a combination of several of them; other and specific embodiment One or two the same.

[0042] In the present embodiment, when the viscosity modifier is a composition, various viscosity modifiers are combined in an arbitrary ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com