Non-explosive mixed refrigerant for re-liquefying device in system for supplying fuel to high-pressure natural gas injection engine

A mixed refrigerant and fuel supply system technology, which is applied to fuel heat treatment devices, engine control, oil supply devices, etc., can solve the problems of complex device configuration and low efficiency, reduce thermal stress, reduce heat load, and safely recycle The effect of liquefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

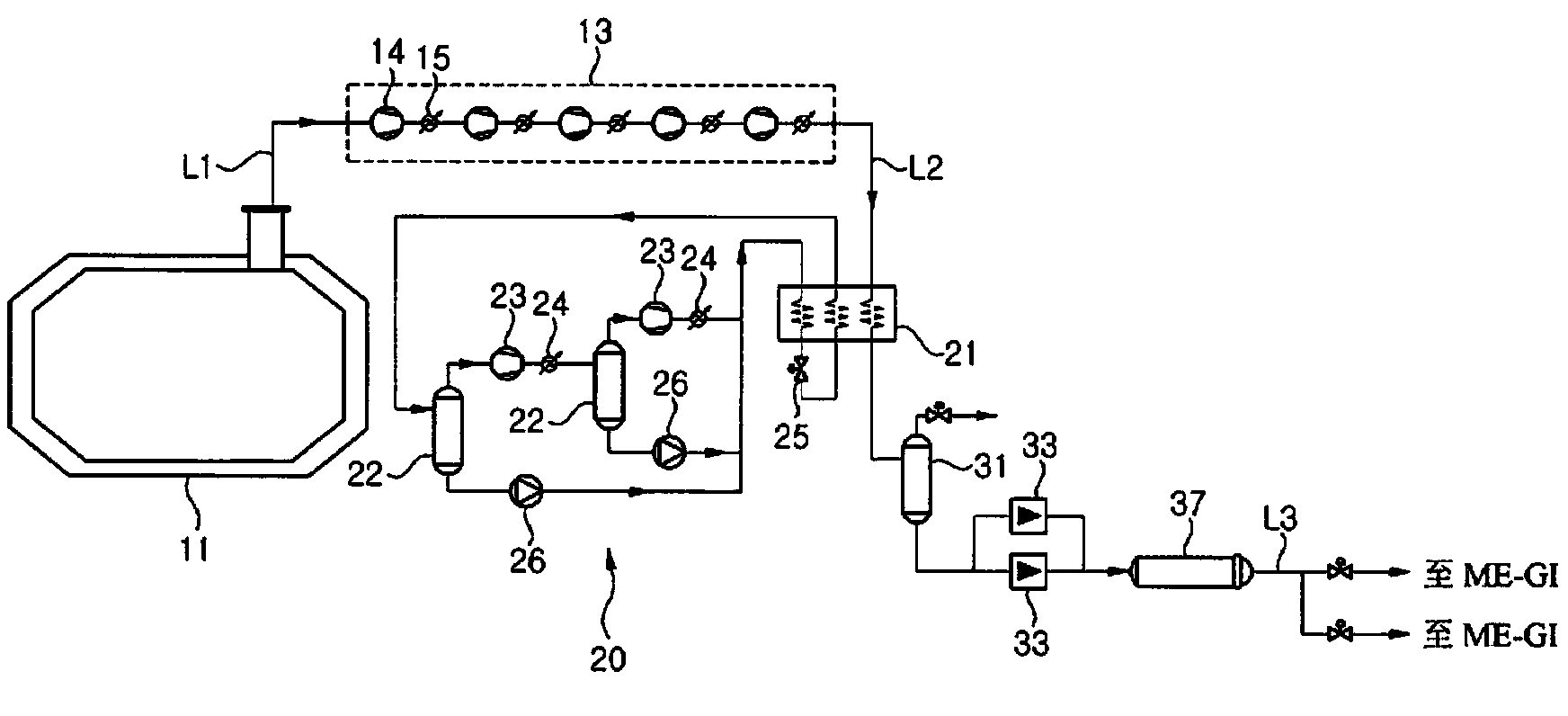

[0038] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, this invention may be embodied in different forms and should not be construed as limited to the embodiments set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

[0039] The International Maritime Organization (IMO) stipulates that nitrogen oxides (NOx) in ship exhaust gas X ) and sulfur oxides (SO X ) emissions, and also attempts to regulate carbon dioxide (CO 2 ) emissions. Specifically, regarding nitrogen oxides (NO X ) and sulfur oxides (SO X ) The subject of the regulations was raised in the 1997 International Convention on the Prevention of Marine Pollution from Ships (MARPOL). Eight years later, the agreement met the implementation requirements and entered into force in May 2005. Cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com