Layer by layer self-assembly compound nanofiltration membrane based on natural cellulose polyelectrolyte and preparation method

A natural cellulose and composite nanofiltration membrane technology, applied in the field of membrane separation, can solve the problems of undiscovered natural cellulose polyelectrolyte composite nanofiltration membrane, and achieve good anti-pollution performance, cost reduction, and controllable membrane layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

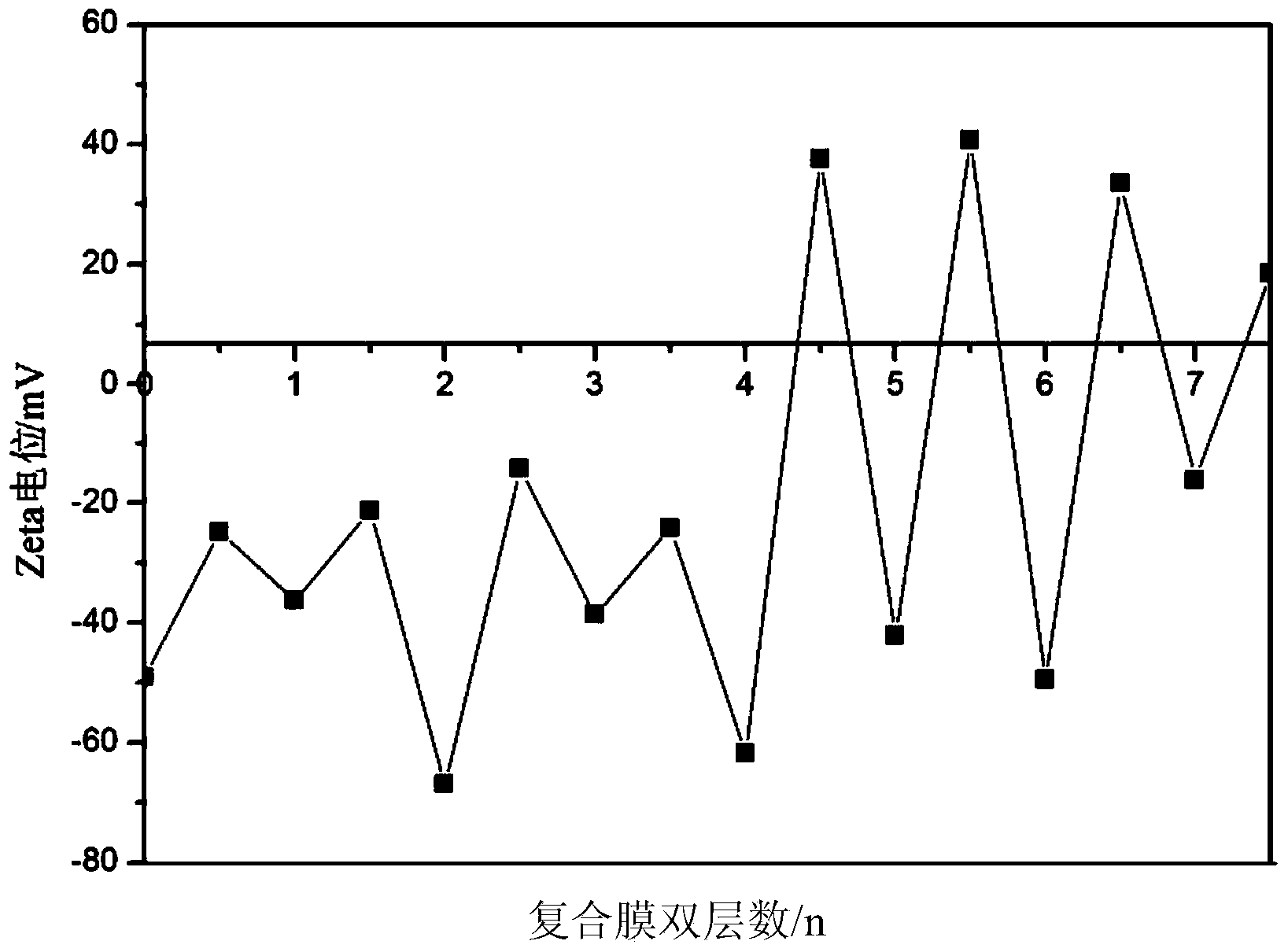

Method used

Image

Examples

Embodiment 1

[0022] (1) Pretreat the base membrane to make its surface negatively charged: use polyacrylonitrile ultrafiltration membrane as the base membrane, immerse it in a 2.0 mol / L sodium hydroxide solution, and treat it at 30°C for 90 minutes. Take it out and rinse it repeatedly with deionized water to a pH of 7.

[0023] (2) Preparation of polyelectrolyte solution: Polydimethyldiallylammonium chloride (PDDA) is selected and dissolved in deionized water to prepare a cationic polyelectrolyte solution with a concentration of 7.0 g / L. Sodium carboxymethyl cellulose (CMC-Na) is dissolved in deionized water to prepare an anionic cellulose polyelectrolyte solution with a concentration of 1.0 g / L. Among them, when preparing an anionic polyelectrolyte solution, sodium carboxymethyl cellulose (CMC-Na) should be slowly added under stirring to prevent it from agglomerating and preventing dissolution. After stirring evenly, let it stand for 24 hours to defoam and make it fully dissolved.

[0024] (...

Embodiment 2

[0028] (1) Pretreat the base membrane to make its surface negatively charged: use polyacrylonitrile ultrafiltration membrane as the base membrane, immerse it in a 2.0 mol / L sodium hydroxide solution, and treat it at 30°C for 90 minutes. Take it out and rinse it repeatedly with deionized water to a pH of 7.

[0029] (2) Preparation of polyelectrolyte solution: Polydimethyldiallylammonium chloride (PDDA) is selected and dissolved in deionized water to prepare a cationic polyelectrolyte solution with a concentration of 5.0 g / L. Sodium carboxymethyl cellulose (CMC-Na) is dissolved in deionized water to prepare an anionic cellulose polyelectrolyte solution with a concentration of 2.0 g / L. Among them, when preparing an anionic polyelectrolyte solution, sodium carboxymethyl cellulose (CMC-Na) should be slowly added under stirring to prevent it from agglomerating and preventing dissolution. After stirring evenly, let it stand for 24 hours to defoam and make it fully dissolved.

[0030] (...

Embodiment 3

[0034] (1) Pretreat the base membrane to make its surface negatively charged: use polyacrylonitrile ultrafiltration membrane as the base membrane, immerse it in a 2.0 mol / L sodium hydroxide solution, and treat it at 30°C for 60 minutes. Take it out and rinse it repeatedly with deionized water to a pH of 7.

[0035] (2) Preparation of polyelectrolyte solution: Polydimethyldiallylammonium chloride (PDDA) is selected and dissolved in deionized water to prepare a cationic polyelectrolyte solution with a concentration of 5.0 g / L. Sodium carboxymethyl cellulose (CMC-Na) is dissolved in deionized water to prepare an anionic cellulose polyelectrolyte solution with a concentration of 2.0 g / L. Among them, when preparing an anionic polyelectrolyte solution, sodium carboxymethyl cellulose (CMC-Na) should be slowly added under stirring to prevent it from agglomerating and preventing dissolution. After stirring uniformly, let it stand for 18h to degas to make it dissolve fully.

[0036] (3) Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com