Catalyst separation device for cyclohexanone ammoximation reaction

A separation device and catalyst technology, which is applied in the direction of filtration separation, separation method, oxime preparation, etc., can solve the problems of reduced effective volume of reaction kettle, unfavorable continuous production, increased equipment investment, etc., to reduce quantity and investment, increase Large volume, effect of reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

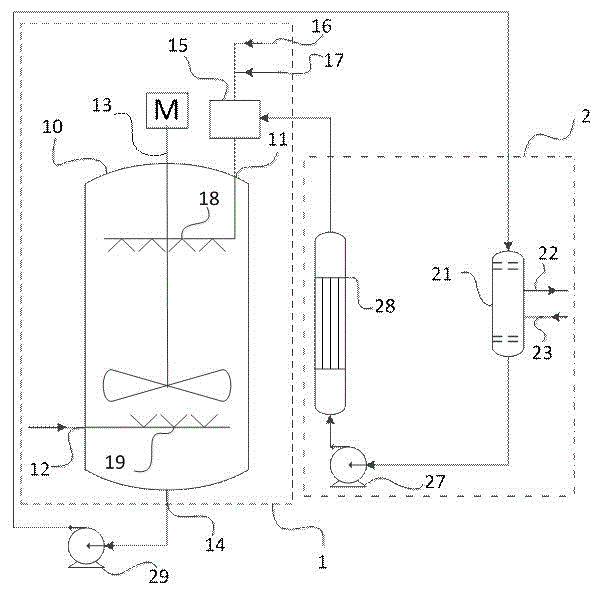

[0036] used in this experiment figure 1 The flow shown carries out the cyclohexanone ammoximation reaction catalyst separation. Ammoximation reaction charging amount is as shown in table 1:

[0037] name

Feed unit

temperature

28.77kg / h

tert-butanol

81.71kg / h

31.34kg / h

5.48kg / h

room temperature

[0038] Table 1 Feed amount of oximation reaction

[0039] The catalyst concentration of the reaction liquid output pump 29 is 3%. The membrane filter 21 is backflushed every 2-3 minutes.

Embodiment 2

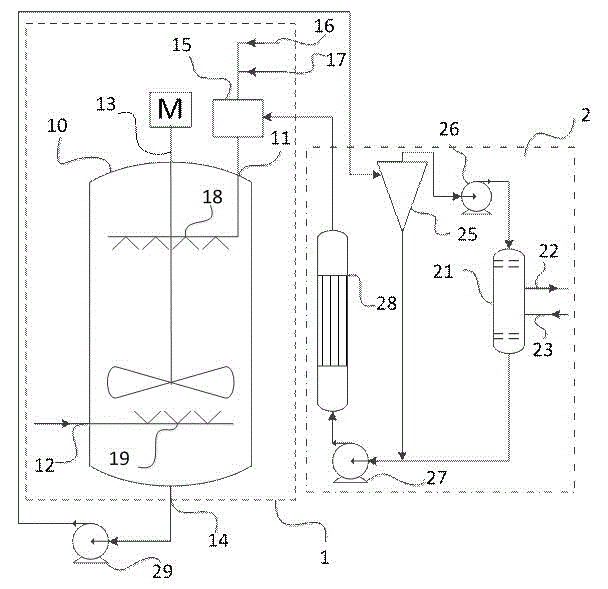

[0041] In this experiment, for the convenience of comparison, the figure 2 In the process shown, the cyclohexanone ammoximation catalyst is separated, that is, a suspension separator 25 is added, and the rest of the conditions are the same as in Experiment 1.

[0042] In this experiment, the catalyst concentration of the reaction liquid output pump 29 is 3%, and the catalyst concentration of the liquid delivery pump 26 at the top of the hydrocyclone separator 25 is 0.8%. The membrane filter 21 is recoiled approximately every 40 minutes, and the recoil frequency of the membrane filter is greatly reduced.

[0043] In summary, the catalyst separation device provided by the present invention is suitable for the cyclohexanone ammoximation reaction and its catalyst separation. Since the membrane filter is placed outside, the volume of the reactor is increased, and a pre-filtration device is added at the same time, which reduces the membrane filtration rate. The load of the filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com