Method for extracting aluminum oxide from coal ash through hot-wall reaction

A technology for fly ash and alumina, which is applied in the removal of alumina/aluminum hydroxide and solid waste, can solve the problems that the dust-containing exhaust gas treatment is difficult to solve, restricts the industrial scale application, and the gas velocity of the reaction equipment is high. Facilitate exhaust gas treatment, realize comprehensive utilization of resources, and reduce the effect of reaction exhaust gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

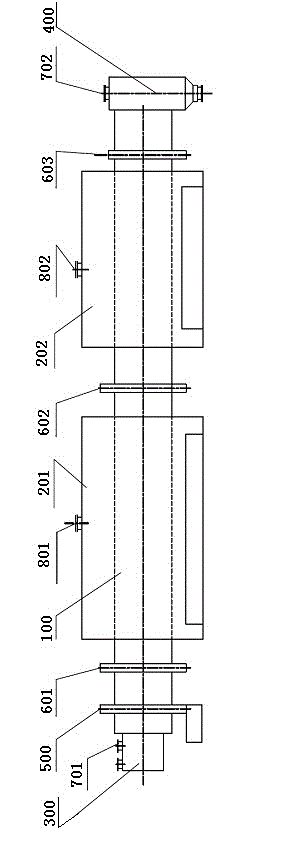

[0026] like figure 1 , figure 2 As shown, the method for extracting alumina from fly ash by using hot wall reaction in this embodiment uses external heating to provide heat for the reaction process of extracting alumina by high-temperature roasting of fly ash, and the reaction of fly ash materials in the reaction equipment The heat required for the reaction is provided by the heating furnace outside the reaction cylinder using high-temperature flue gas generated by burning natural gas with a burner. The heat is indirectly transferred to the material through the wall of the reaction cylinder, and the fly ash absorbs the heat from the heating furnace to complete the extraction. Aluminum oxide reaction process. The material is not in direct contact with the high-temperature gas, and the tail gas discharged from the reaction cylinder is only the process gas generated during the reaction process.

[0027] The reaction equipment of the present invention is such as figure 1 , ...

Embodiment 2

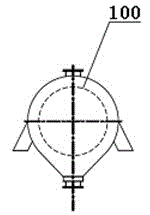

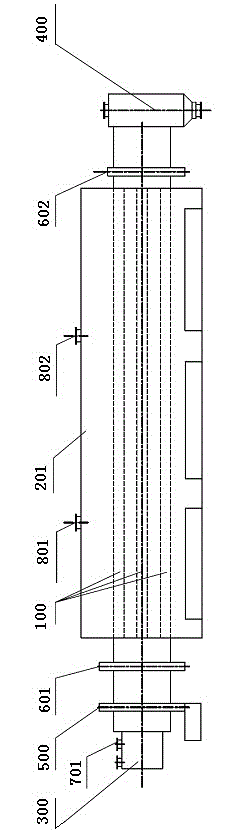

[0030] like image 3 , Figure 4 As shown, the equipment is a multi-tube structure composed of 7 reaction tubes. The reaction equipment adopts a one-piece one-chamber structure. In the multi-tube structure, the reaction tubes formed by the reaction tubes are evenly distributed along the circumferential direction. Driven by the transmission system to rotate simultaneously. The reaction mass is heated and conveyed in the reaction tube. The included angle between each reaction tube and the horizontal plane is 8°, so as to transfer the reaction materials. Other parts of the structure are the same as in Embodiment 1.

[0031]

Embodiment 3

[0033] Adopt the equipment in embodiment one or embodiment two, the specific process of a kind of method of utilizing hot wall reaction of the present invention to extract alumina from fly ash is as follows: first fly ash and ammonium sulfate mixed material are fed by equipment feed end Entering the reaction cylinder, the material is conveyed forward with the rotation of the reaction cylinder, the reaction product is aluminum sulfate, which is discharged from the discharge end, and the generated ammonia, water vapor and sulfur trioxide gas are discharged through the tail gas outlet, and the rotation speed of the reaction cylinder is 10rpm; during the conveying process, the material is heated by the heating furnace installed outside the reaction cylinder, and the temperature of the heating furnace is 1000°C.

[0034] The invention adopts the external heating method of the furnace and the reaction cylinder, which has high thermal efficiency; the tail gas discharged from the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com