High-efficiency anti-blocking synchronous nitration and denitrification hierarchy biological aerated filter

A biological aerated filter and synchronous nitrification technology, which is applied in the direction of aerobic and anaerobic treatment, can solve the problems of difficult to realize synchronous nitrification and denitrification, small specific surface area of filler, low reaction efficiency, etc., to achieve the benefit of oxygen transmission , improve the mass transfer performance, and the effect of uniform water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

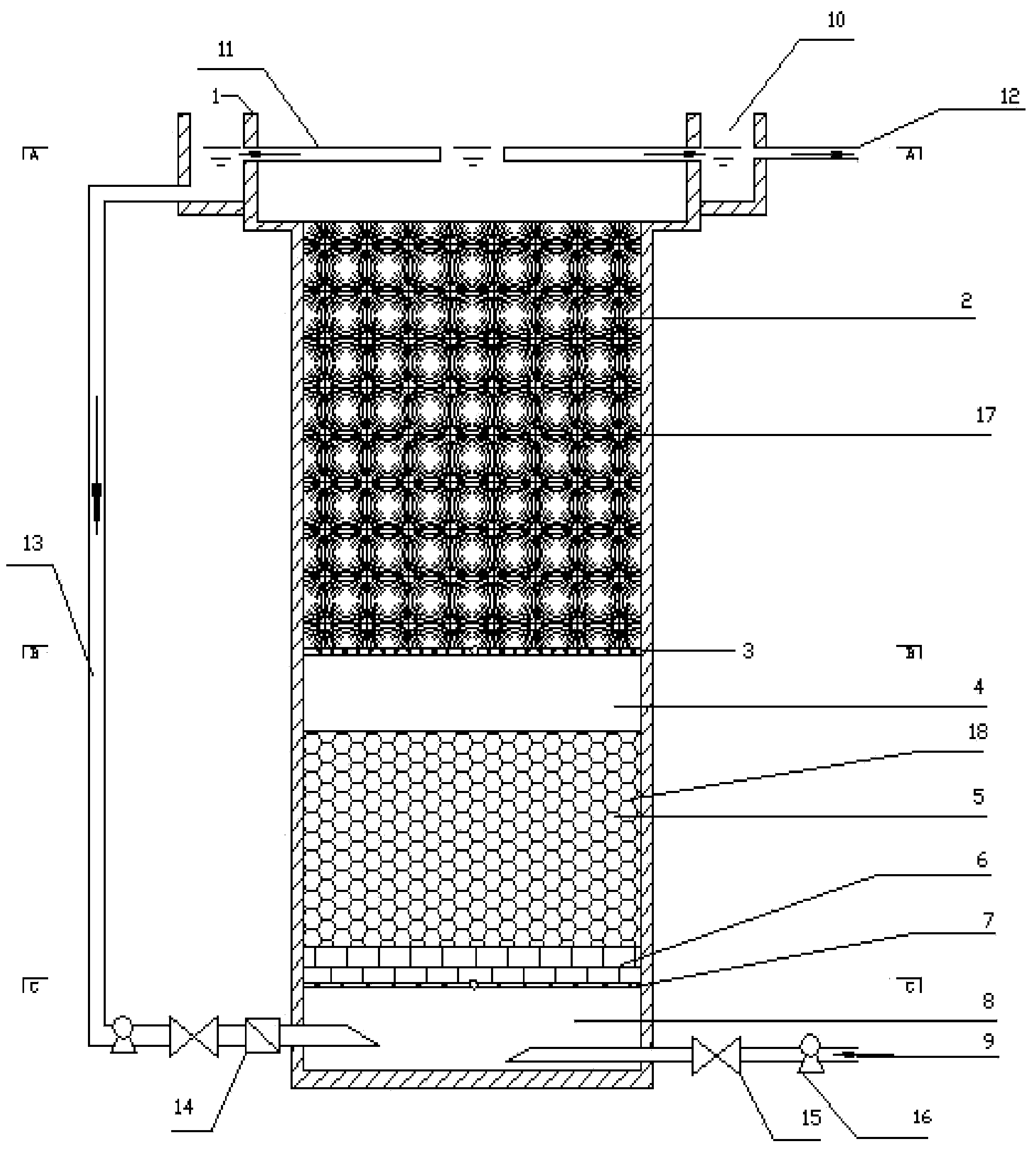

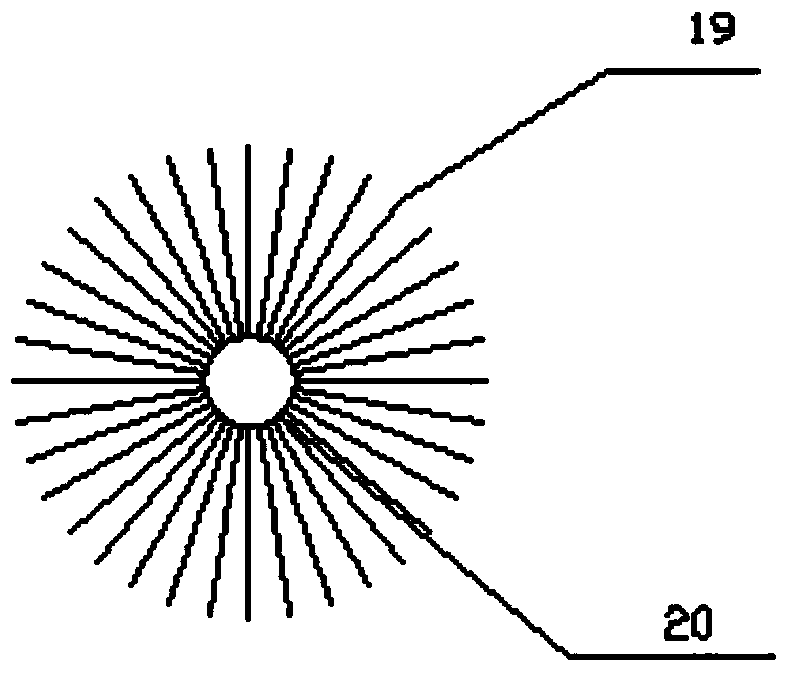

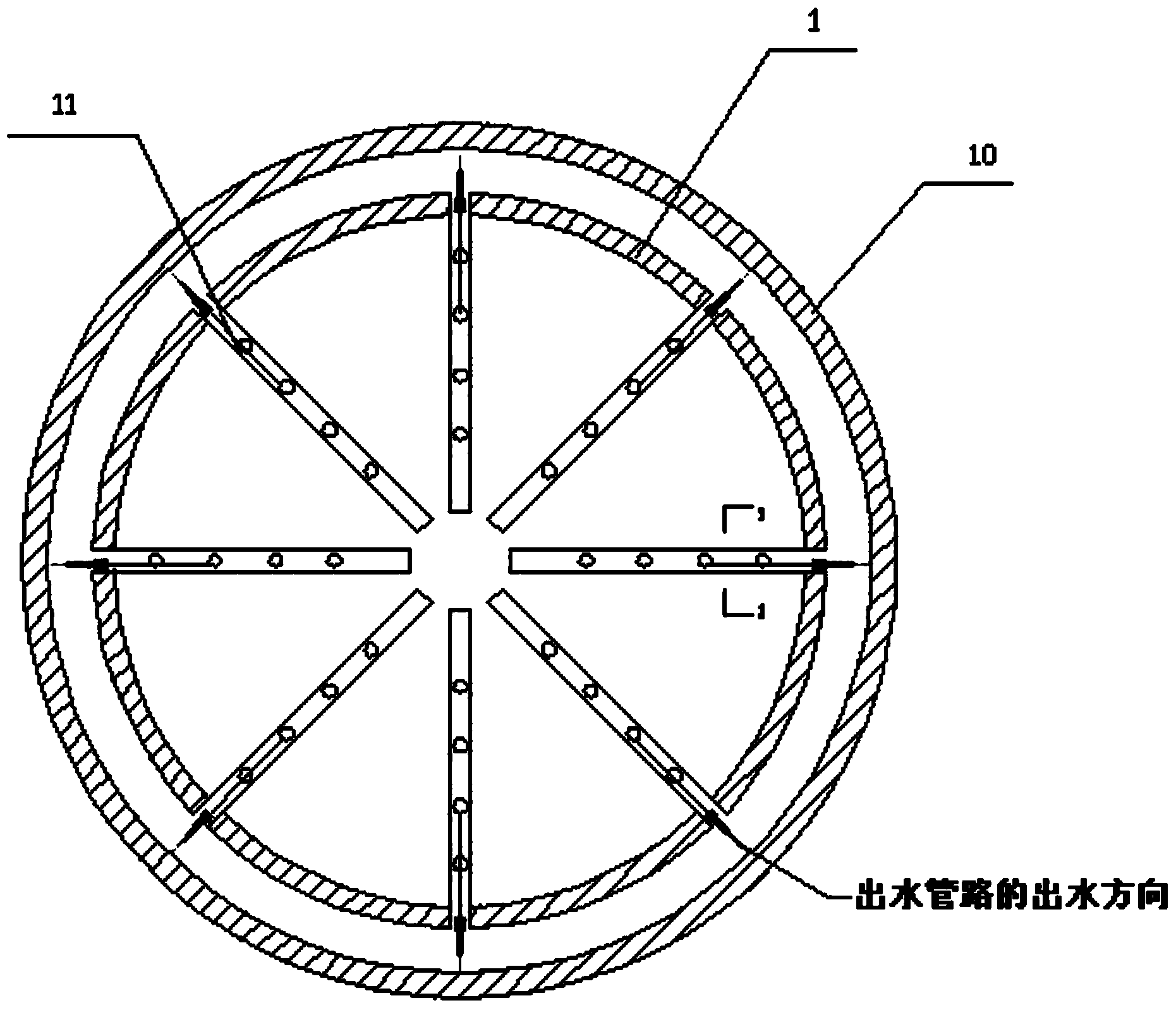

[0029] Specific implementation mode one: combine Figure 1-7 Describe this embodiment, a high-efficiency anti-clogging synchronous nitrification and denitrification layered biological aerated filter, the overall structural space of the biological aerated filter is arranged in partitions: a mixed area for water distribution and denitrification, and a biological filter concurrently Oxygen reaction zone, aerobic zone, drainage zone; the mixed zone for water distribution and denitrification includes water inlet pipeline 9, water distribution zone 4, return pipeline 13 and premixing zone 8, and the aerobic zone 5 is arranged with Aeration pipeline 7 and traditional particle packing 18; said aerobic area 2 is arranged with aeration pipeline 3 and flexible fiber ball packing 17;

specific Embodiment approach 2

[0030] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the nitrogen-containing sewage enters the biological aerated filter 1 through the water inlet pipeline 9 through the pump 16, and the backflow water of the return pipeline 13 is in the premixing zone 8 mix. Other steps and parameters are the same as those in Embodiment 1.

[0031] In this embodiment, according to the total nitrogen concentration and removal efficiency, the reflux ratio is adjusted to effectively control the concentration of carbon sources entering the facultative oxygen zone 5, and provide electron acceptors for denitrification and denitrification for the denitrifying bacteria in the facultative oxygen zone 5.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the biological aerated filter adopts layered aeration, and the aeration pipeline 7 arranged in the aerobic zone 5 has holes on both sides. The aeration pipeline 3 arranged in the aerobic zone 2 has holes on both sides. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

[0033] In this embodiment, the amount of dissolved oxygen is controlled by a valve to obtain different amounts of dissolved oxygen between facultative and aerobic, forming a facultative and aerobic environment, and realizing synchronous nitrification and denitrification. The aeration pipeline 7 inflates the aerobic zone 5, the air-water ratio is (2:1)-(3:1), and the dissolved oxygen in the aerobic zone 5d is controlled to be 0.1-0.3 mg / L; the aeration pipeline 3 supplies The aerobic zone 2 is inflated, the air-water ratio is (8:1)-(12:1), and the dissolved oxygen in the aerobic zone 2d is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com