Method for preparing 3,4-diamino-benzenesulfonamide

A technology for diaminobenzenesulfonamide and o-nitroaniline is applied in the field of preparing 3,4-diaminobenzenesulfonamide, and can solve the problems of difficulty in industrialization, complicated operation, slow reaction rate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

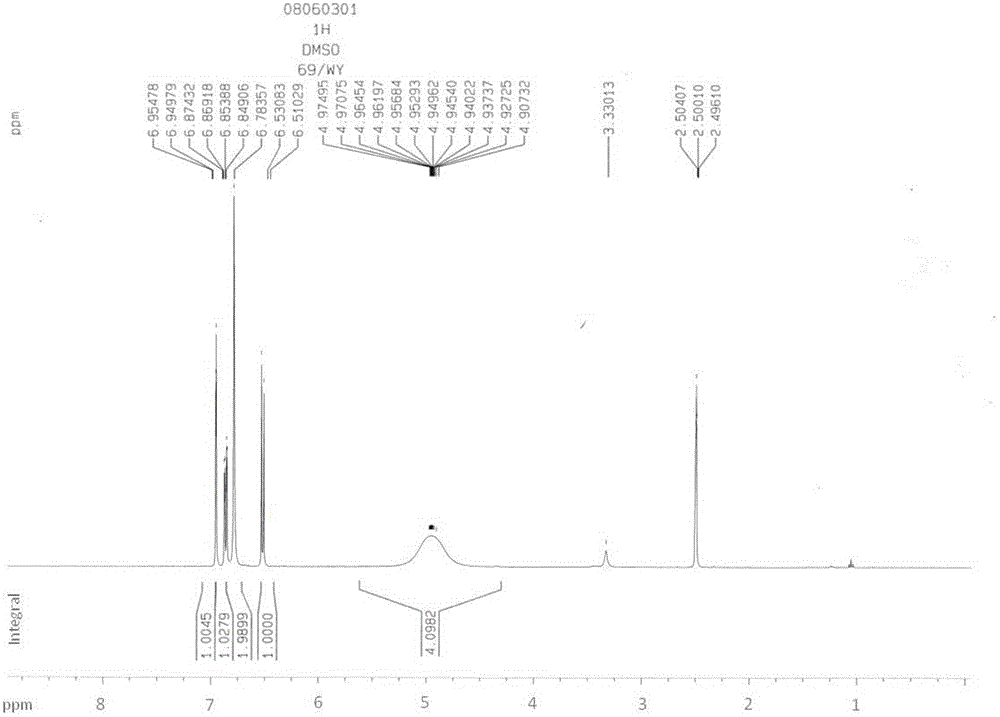

Image

Examples

Embodiment 1

[0018] ① Add 100g of chlorosulfonic acid into the reaction bottle, stir and control the temperature at 0°C, slowly add 30g of o-nitroaniline in batches, control the system temperature at 0°C and continue to stir for 2 hours. After the reaction is completed, pour the reaction product into ice water and stir for 0.5 Filtrate after h to obtain 51.4g of solid intermediate a, then slowly add intermediate a in batches to 300g of ammonia water with a concentration of 30% by mass, control the temperature at 5°C and stir for 0.5h, and steam out the reaction solution after the reaction is completed After filtering and drying the precipitated solids, 45.7 g of intermediate b was obtained for use (yield: 96%).

[0019] ② Add 45.7g of intermediate b, 0.5g of ferric chloride, 2.74g of activated carbon, and 274g of ethanol in sequence in a reaction flask with a reflux device, and heat up to 70°C to condense and reflux. At the beginning of reflux, slowly add hydrazine hydrate dropwise, while ...

Embodiment 2

[0021] ①Add 100g of chlorosulfonic acid into the reaction bottle, stir and control the temperature at 5°C, slowly add 25g of o-nitroaniline in batches, control the system temperature at 0°C and continue to stir for 2h. After the reaction is completed, pour the reaction product into ice water and stir for 0.5 Filtrate after h to obtain 42.8g of solid intermediate a, then slowly add intermediate a in batches to 400g of ammonia water with a concentration of 25% by mass, control the temperature at 10°C and stir for 0.5h, and steam out the reaction solution after the reaction is completed The water and the precipitated solid matter were filtered and dried to obtain 38 g of intermediate b for use (yield: 96%).

[0022] ② Add 38g of intermediate b, 0.38g of ferric chloride, 1.9g of activated carbon, and 190g of ethanol in sequence in a reaction flask with a reflux device, and heat up to 60°C to condense and reflux. For reaction, 38g of hydrazine hydrate was added dropwise, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com