Liquefaction method of lignin for preparing thermoplastic phenolic resin

A technology of phenolic resin and lignin, applied in the field of new acid catalyst for lignin liquefaction modification, can solve problems such as serious equipment corrosion, environmental pollution, poor catalytic effect, etc., and achieve high production efficiency, cost reduction, and reaction speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

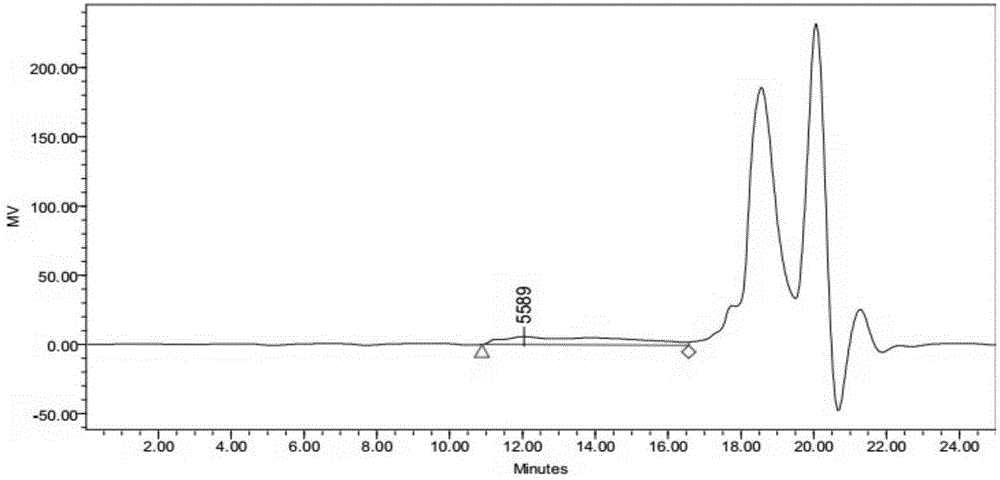

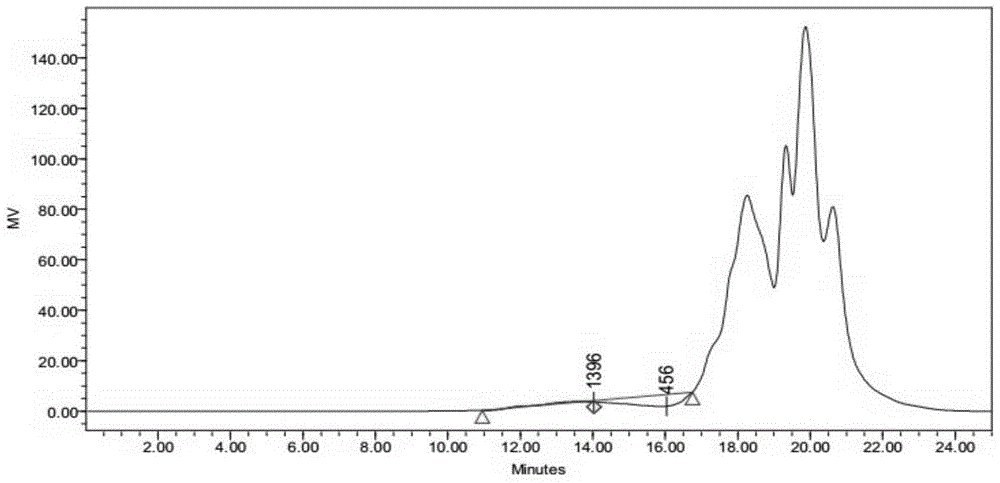

[0023] A lignin liquefaction method for preparing thermoplastic phenolic resin, the liquefaction method is as follows: phenol, heteropolyacid catalyst and enzymatic lignin are mixed, heated to 90°C-160°C, and reacted for 1-3h. Among them, the mass ratio of acid catalyst to phenol is 0.5-4:100, the mass ratio of lignin to phenol is 10-60:100, the liquefaction residue rate is 0.5-20%, and the yield of phenolic compounds is 40-70%. , the molecular weight of the liquefied residue is 1100-2300, and the dispersion coefficient (Mw / Mn) is reduced by 50-90%. The lignin that participates in this reaction is enzymatic lignin, which can be extracted from the residue of plant raw material biorefinery (biofuel ethanol or butanol) containing cellulose and hemicellulose.

Embodiment 2

[0025] Add a certain amount of phenol, enzymatic lignin (accounting for 33% of the mass of phenol) and phosphotungstic acid (accounting for 0.5% of the mass of phenol) into the reactor, the reaction temperature is 95 ° C, and the reaction time is 2 hours to obtain enzymatic lignin The liquefied product has a residue rate of 11.5%, a yield of phenolic compounds of 47%, and a liquefied residue molecular weight of 1910.

Embodiment 3

[0027] Add a certain amount of phenol, enzymatic lignin (33% of phenol mass) and phosphotungstic acid (1% of phenol mass) into the reactor, the reaction temperature is 115°C, and the reaction time is 1.5h to obtain enzymatic lignin liquefaction The product has a residue rate of 9.7%, a yield of phenolic compounds of 56%, and a liquefaction residue molecular weight of 1790.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com