Anhydride-free molecular distilled epoxy VPI (vacuum pressure impregnation) impregnated resin and preparation method thereof

A technology of molecular distillation and resin impregnation, which is applied in the field of anhydride-free molecular distillation epoxy VPI impregnation resin and its preparation, which can solve the problems of high equipment and operation process requirements, easy moisture absorption, etc., and achieve good use manufacturability and strong dilution ability , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

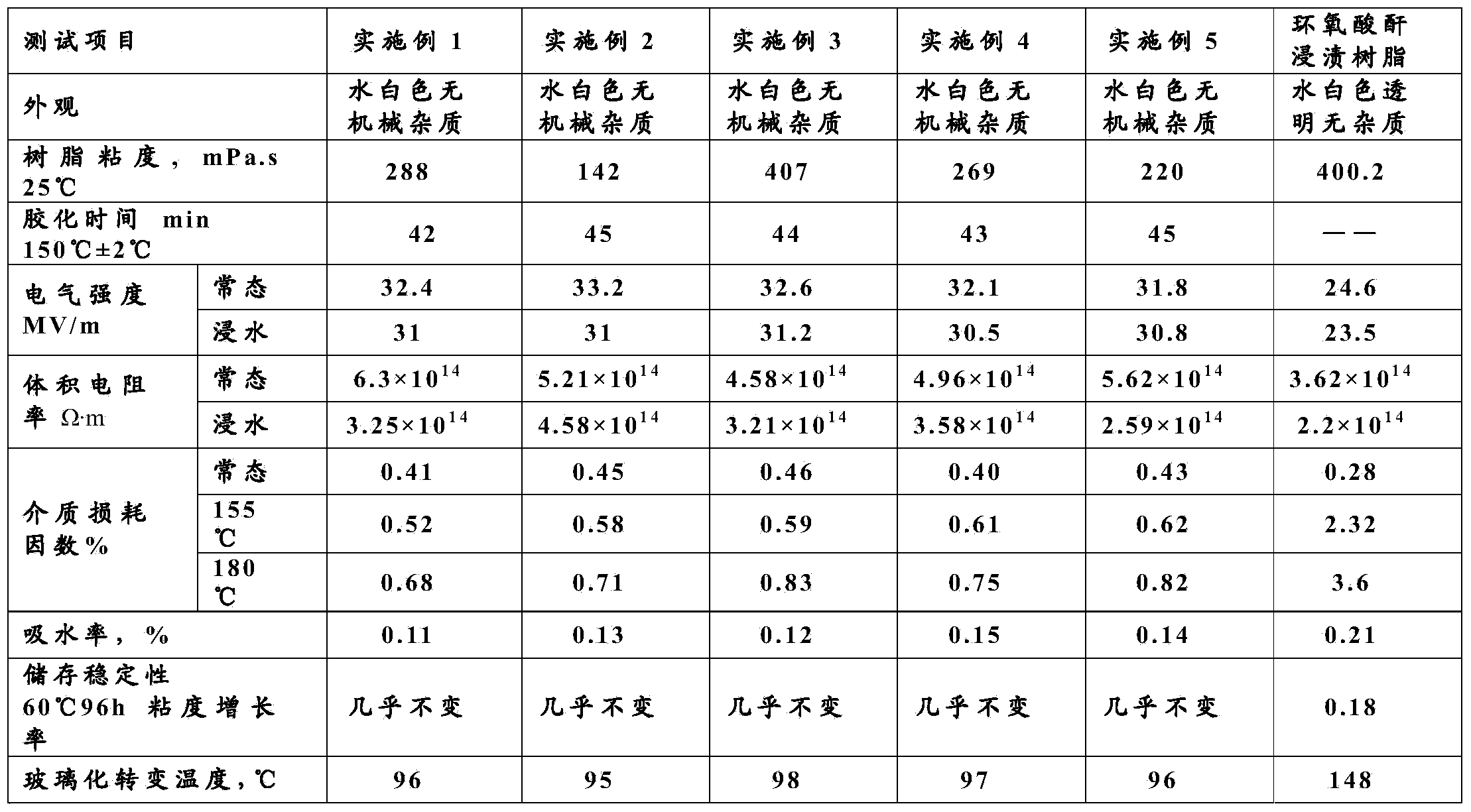

Examples

Embodiment 1

[0024] This embodiment provides an anhydride-free molecular distillation epoxy VPI impregnated resin and a preparation method thereof.

[0025] The raw material composition of anhydride-free molecular distillation epoxy VPI impregnating resin is as follows: molecular distillation bisphenol A epoxy resin JF-158: 750g; 3,4-epoxycyclohexane carboxymethyl ester: 250g; silane defoamer: 1.5 g; self-made complex curing agent: 50g.

[0026] The preparation method of self-made complex curing agent is as follows:

[0027] Accurately weigh 60g of zinc neodecanoate, 20g of aluminum acetylacetonate and 20g of 594 boron amine complex into a 150ml three-necked bottle, and slowly raise the temperature; raise the temperature to 105°C±5°C and keep it for 1.5h, then cool down to obtain the curing agent.

[0028] The preparation process of anhydride-free molecular distillation epoxy VPI impregnating resin is as follows: Accurately weigh 750g of molecular distillation bisphenol A epoxy resin (JF-...

Embodiment 2

[0030] This embodiment provides an anhydride-free molecular distillation epoxy VPI impregnated resin and a preparation method thereof.

[0031] The raw material composition of anhydride-free molecular distillation epoxy VPI impregnating resin is as follows: molecular distillation bisphenol F epoxy resin (JF-158-1) 750g; 3,4-epoxy cyclohexane carboxylate methyl ester: 250g; silane defoaming Agent: 1.5g; self-made complex curing agent: 50g.

[0032] The preparation method of self-made complex curing agent is as follows:

[0033] Accurately weigh 90g of zinc caprylate and 36g of triethanolamine into a 150ml three-neck bottle, and slowly raise the temperature; raise the temperature to 100°C±5°C and keep it for 2 hours, then cool down to obtain the curing agent.

[0034] The preparation process of anhydride-free molecular distillation epoxy VPI impregnating resin is as follows: Accurately weigh 750g of molecular distillation bisphenol F epoxy resin (JF-158-1) in a beaker, heat and...

Embodiment 3

[0036] This embodiment provides an anhydride-free molecular distillation epoxy VPI impregnated resin and a preparation method thereof.

[0037] The raw material composition of anhydride-free epoxy VPI impregnating resin is as follows: molecularly distilled bisphenol A epoxy resin (JF-158) 750g; vinyl dioxide cyclohexene: 250g; silane defoamer: 1.5g; self-made complex curing agent : 50g.

[0038] The preparation method of self-made complex curing agent is as follows:

[0039]Accurately weigh 50g of zinc naphthenate, 30g of chromium acetylacetonate and 20g of benzylamine into a 150ml three-neck bottle, and slowly raise the temperature; raise the temperature to 95°C±5°C and keep it for 1 hour, then cool down to obtain the curing agent.

[0040] The preparation process of anhydride-free molecular distillation epoxy VPI impregnating resin is as follows: Accurately weigh 750g of molecular distillation bisphenol A epoxy resin (JF-158) in a beaker, heat and stir, when the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com