Method for preparing 40% sodium polyaspartate aqueous solution

A technology of polyaspartic acid sodium and saline solution, which is applied in the field of polyaspartic acid preparation, and can solve the problems of less application and complicated process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For further illustrating the present invention, specifically illustrate in conjunction with following examples:

[0017] 1 Formation reaction of polysuccinimide

[0018] 1) Catalyst

[0019] Polyaspartic acid (salt) can also be prepared under non-catalytic conditions, but in actual production, catalysts are usually added to speed up the reaction speed and shorten the reaction time, and at the same time inhibit the occurrence of side reactions to reduce the generation of by-products. Reduce product color. In addition, studies have shown that the use of catalyst polymerization may also improve the biodegradability of the product. The catalysts used in different raw material routes are similar, and a wide range of catalysts can be selected. Phosphoric acid is the catalyst used earlier, but when it was used in the early stage, the amount of phosphoric acid was large, and even the raw materials were dissolved in a large amount of phosphoric acid for reaction, which not on...

PUM

| Property | Measurement | Unit |

|---|---|---|

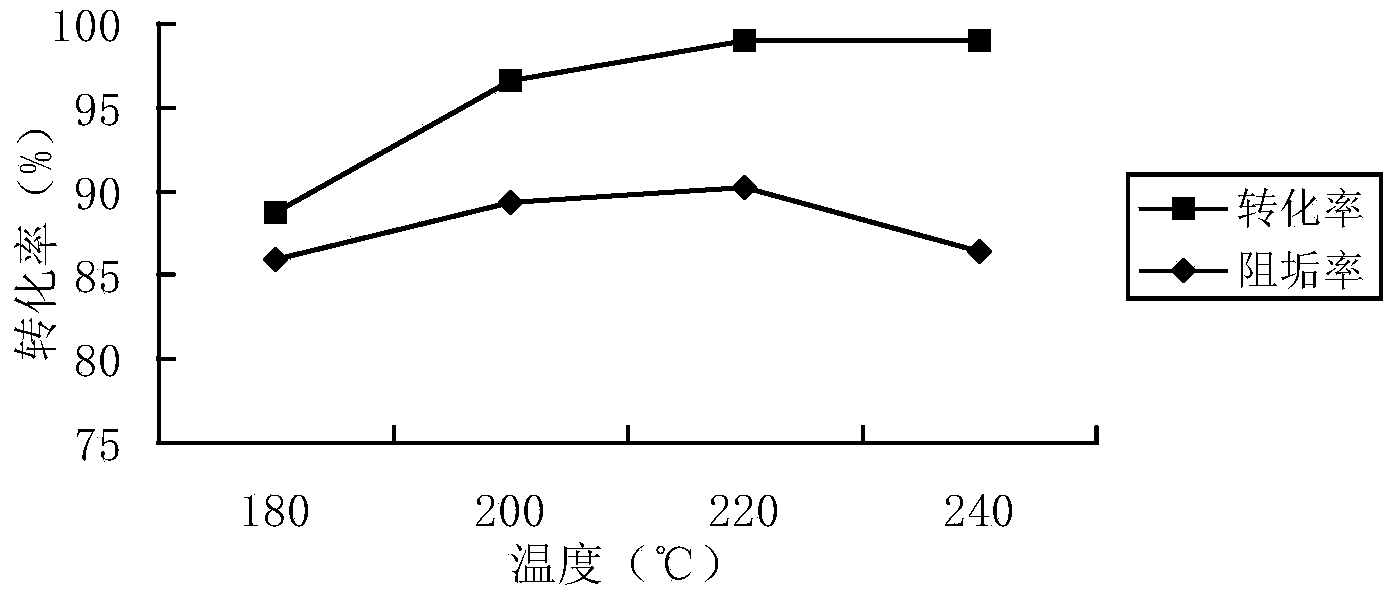

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com