a zno/g-c 3 n 4 Preparation method and application of ozone composite catalyst

A composite catalyst, g-c3n4 technology, applied in the field of water pollution control, can solve the problem of catalyst activity reduction, achieve accelerated degradation and removal, good dispersion, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

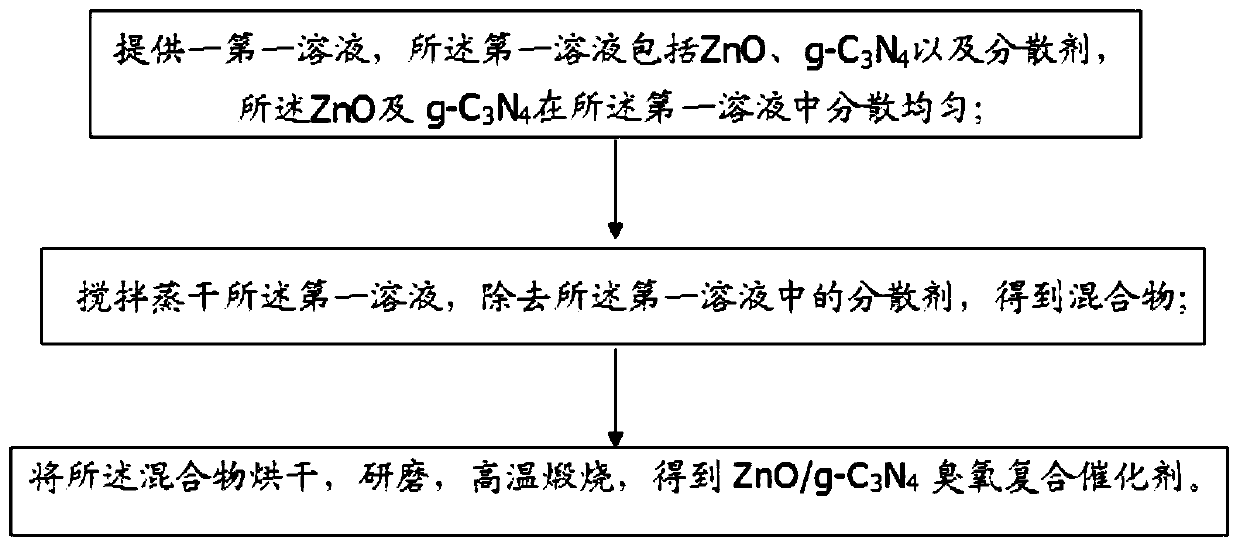

[0033] Such as figure 1 Shown, the embodiment of the present invention ZnO / g-C 3 N 4 The preparation method of ozone composite catalyst, described method comprises the steps:

[0034] Provide a first solution, the first solution includes ZnO, g-C 3 N 4 And dispersant, the ZnO and g-C 3 N 4 uniformly dispersed in the first solution;

[0035] stirring and evaporating the first solution to dryness, removing the dispersant in the first solution to obtain a mixture;

[0036] The mixture is dried, ground, and calcined at high temperature to obtain ZnO / g-C 3 N 4 Ozone composite catalyst.

[0037] Graphite carbon nitride (g-C 3 N 4) is an allotrope of carbon nitride, which has a unique graphite-like layered stacking structure and sp2 hybridized π-conjugated electronic band structure. Because it has a certain absorption for visible light, it also has strong mechanical properties, With the advantages of good thermal stability, acid and alkali corrosion resistance, and easy p...

Embodiment 1

[0045] g-C 3 N 4 preparation of

[0046] Weigh a certain amount of melamine into a crucible, put the crucible into a muffle furnace, and bake it at a heating rate of 5°C / min at 550°C for 2 hours. After the crucible is cooled, take it out to obtain light yellow powder g-C 3 N 4 , grind and set aside.

[0047] ZnO / g-C 3 N 4 preparation of

[0048] Weigh 5.4g g-C 3 N 4 Put the powder in 50ml of absolute ethanol, set the temperature of the ultrasonic cleaner to 30°C, and ultrasonically stir at a speed of 250-300r / min for 30min, then weigh 0.6g of ZnO and mix it in, and ultrasonically stir for 30min under the same conditions , heat the uniformly dispersed sample in a water bath at 80°C, and stir it at a speed of 300-350r / min. Drying, grinding, and finally putting it into a muffle furnace, calcining at 650°C for 2 hours at a heating rate of 3°C / min, and then grinding to obtain the required ZnO / g-C 3 N 4 Ozone composite catalyst.

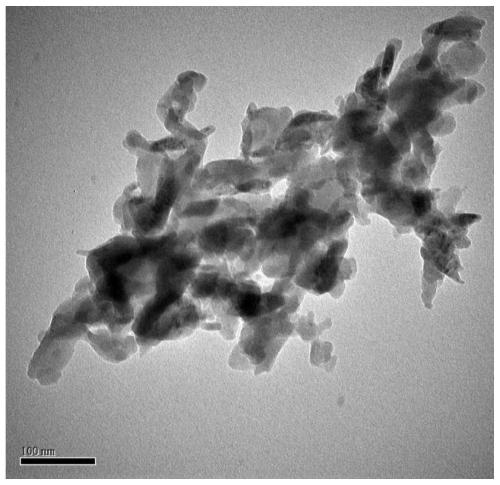

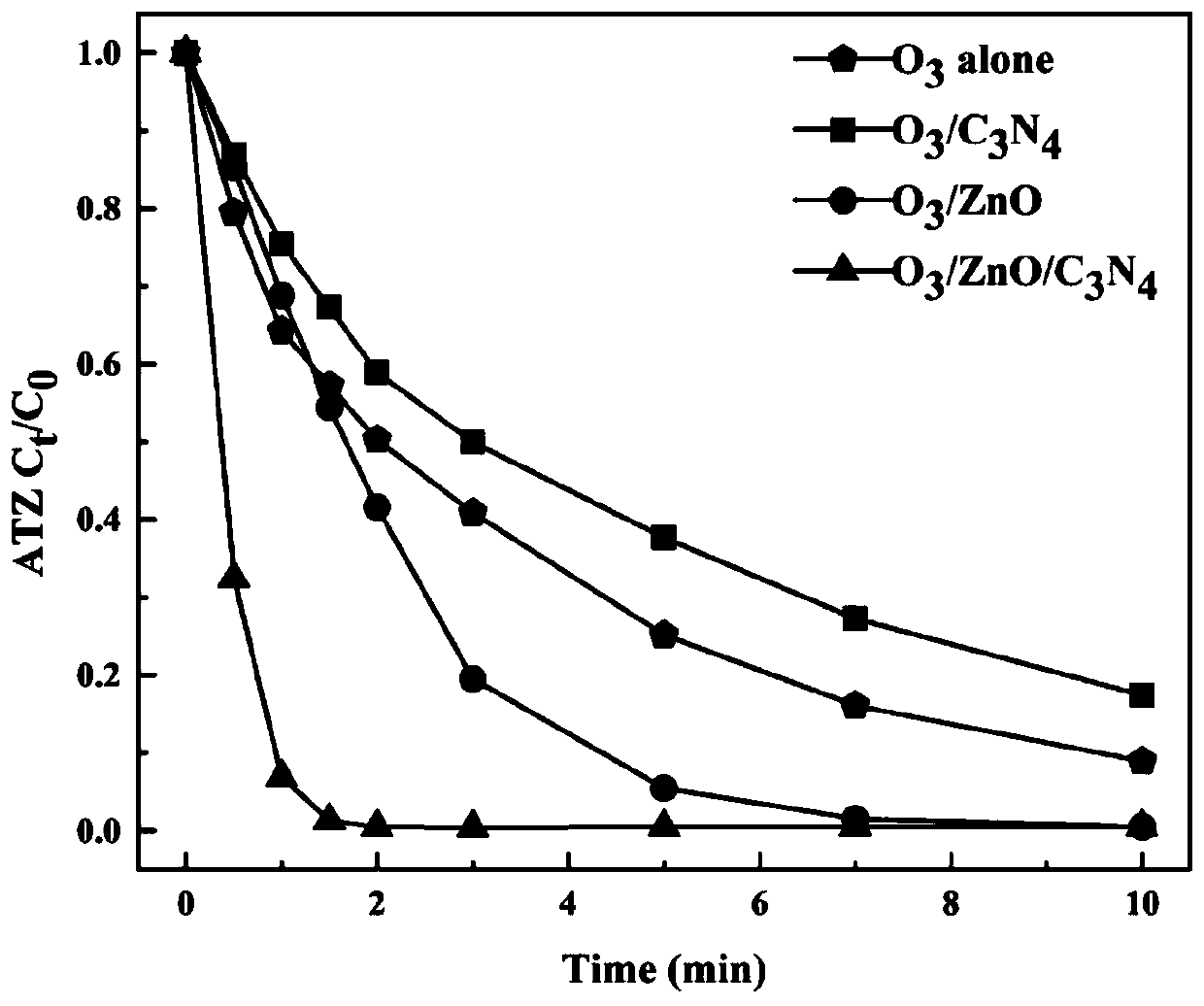

[0049] ZnO / g-C prepared by Example 1 of ...

Embodiment 2

[0053] g-C 3 N 4 preparation of

[0054] Weigh a certain amount of melamine into a crucible, put the crucible into a muffle furnace, and roast it at a heating rate of 5°C / min at 500°C for 4 hours, and take it out after the crucible is cooled to obtain light yellow powder g-C 3 N 4 , grind and set aside.

[0055] ZnO / g-C 3 N 4 preparation of

[0056] Weigh 5.4g g-C 3 N 4 Put the powder in 50ml of anhydrous methanol, set the temperature of the ultrasonic cleaner at 30°C, and perform ultrasonic stirring at a speed of 250-300r / min for 40min, then weigh 0.54g of ZnO and mix it in, and ultrasonically for 30min under the same conditions. Heat the uniformly dispersed sample in a water bath at 70°C and stir at a speed of 300-350r / min. After the anhydrous methanol is evaporated to dryness, put the sample into an electric constant temperature blast drying oven and dry it at 60°C. Dry, grind, and finally put it into a muffle furnace, calcinate at 650°C for 2 hours at a heating ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com