TPE (Thermoplastic Elastomer) material with high temperature resistance

A technology with high temperature resistance and high performance, which is applied in the field of TPE materials, can solve the problems of shortened service life, compression deformation, decreased elastic recovery, and large decline in physical properties, etc., to achieve the effects of prolonging service life, improving heat resistance, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

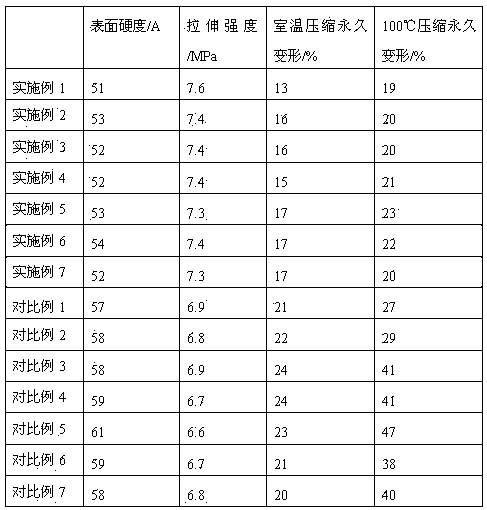

Examples

Embodiment 1

[0018] Example 1 Preparation of TPE material with good high temperature resistance of the present invention (1)

[0019] 1. Take the following raw materials by weight: 100 parts of hydrogenated styrene-butadiene-styrene block copolymer, 90 parts of hydrogenated naphthenic oil, 20 parts of polypropylene, 15 parts of propylene-ethylene random copolymer, CaCO 3 110 parts, 1 part of calcium stearate, 0.2 parts of 2-tert-butyl-4,6-dimethylphenol, 0.6 parts of 2,4,6-tri-tert-butylphenol;

[0020] 2. Put the above raw materials into the mixer and mix at 100-120rpm for 2-3h;

[0021] 3. Put the mixed raw materials into a twin-screw extruder for extrusion and granulation, wherein the temperature of the twin-screw extruder is 180-200°C, and the rotation speed is 260rpm.

Embodiment 2

[0022] Example 2 Preparation of TPE material with good high temperature resistance of the present invention (2)

[0023] 1. Take the following raw materials by weight: 80 parts of hydrogenated styrene-butadiene-styrene block copolymer, 80 parts of hydrogenated naphthenic oil, 15 parts of polypropylene, 20 parts of propylene-ethylene random copolymer, CaCO 3 100 parts, 0.5 parts of calcium stearate, 0.1 parts of 2-tert-butyl-4,6-dimethylphenol, 0.4 parts of 2,4,6-tri-tert-butylphenol;

[0024] 2. Put the above raw materials into the mixer and mix at 100-120rpm for 2-3h;

[0025] 3. Put the mixed raw materials into a twin-screw extruder for extrusion and granulation, wherein the temperature of the twin-screw extruder is 180-200°C, and the rotation speed is 280rpm.

Embodiment 3

[0026] Example 3 Preparation of TPE material with good high temperature resistance of the present invention (3)

[0027] 1. Weigh the following raw materials in parts by weight: 100 parts of hydrogenated styrene-butadiene-styrene block copolymer, 100 parts of hydrogenated naphthenic oil, 20 parts of polypropylene, 15 parts of propylene-ethylene random copolymer, CaCO 3 120 parts, 1 part of calcium stearate, 0.2 parts of 2-tert-butyl-4,6-dimethylphenol, 0.8 parts of 2,4,6-tri-tert-butylphenol;

[0028] 2. Put the above raw materials into the mixer and mix at 100-120rpm for 2-3h;

[0029] 3. Put the mixed raw materials into a twin-screw extruder for extrusion and granulation, wherein the temperature of the twin-screw extruder is 180-200°C, and the rotation speed is 270rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com