Gelatine powder and liquid cement for quickly mixing putty or cement

A blending and putty technology, applied in the direction of adhesives, unsaturated alcohol copolymer adhesives, adhesive types, etc., can solve the problems of surface "skinning, thinning of consistency, energy consumption, etc., and achieve good peeling resistance, The effect of low cost and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of fast reconciling putty or cement glue includes the following components and dosage: PVA1799: 20% (weight percentage, the same below), anionic PAM with a relative molecular weight of 3 million: 16%, HPMC with a viscosity of 120,000 centipoise: 5 %, ethanol: 3%, deionized water: 56%.

[0038] The preparation process of the glue solution includes weighing the raw material ingredients according to the above weight percentage ratio, mixing with a conical vertical screw mixer, a V-shaped mixer or a dough mixer, stirring for 0.5 hours, and passing through a shaking sieve or a vibrating sieve. Separation of large particles, etc., first made into powder, sampling and quality inspection against technical indicators, that is, the production of rubber powder products that can be quickly reconciled and dissolved. Then put it into a dough mixer, add ethanol and tap water, and stir for 40 minutes to prepare a glue solution with a solid content of 40% and a viscosity of 4600 ...

Embodiment 2~5

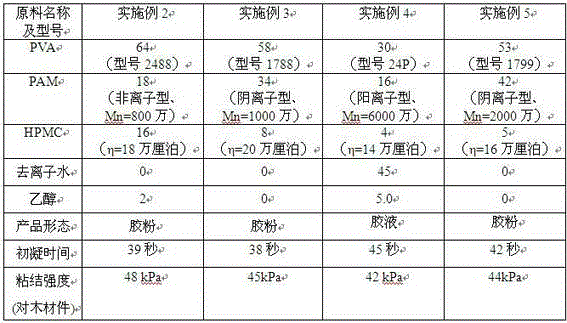

[0041] The manufacturing process of the rubber powder and the glue solution of embodiments 2 to 5 is basically the same as in the above-mentioned embodiment 1, and the raw material formula of each example is shown in Table 1:

[0042] Table 1 The raw material formula table of embodiment 2~5 glue Unit: %

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com