Algae cell breaking method

A method of crushing and algal cell technology, applied in microorganism-based methods, biochemical equipment and methods, and microbial dissolution, etc., which can solve the problems of local high temperature caused by ultrasonic treatment, reduction of protein activity, and difficulties in industrialization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Needle-plate corona discharge method: Weigh a certain amount of algae powder and dissolve it in deionized water, place it in the reactor and use the needle-plate corona discharge method for treatment, control the output voltages to be 8, 10, 12kV respectively, and discharge 1, 3, 5, 10min, the frequency is 50Hz;

[0020] Other methods: take the same amount of algae powder separately and use low concentration CaCl 2 Extraction method, SDS extraction method, cell swelling method, cellulase extraction method, repeated freeze-thaw method, liquid nitrogen grinding method, needle plate corona discharge method, ultrasonic crushing method for cell disruption;

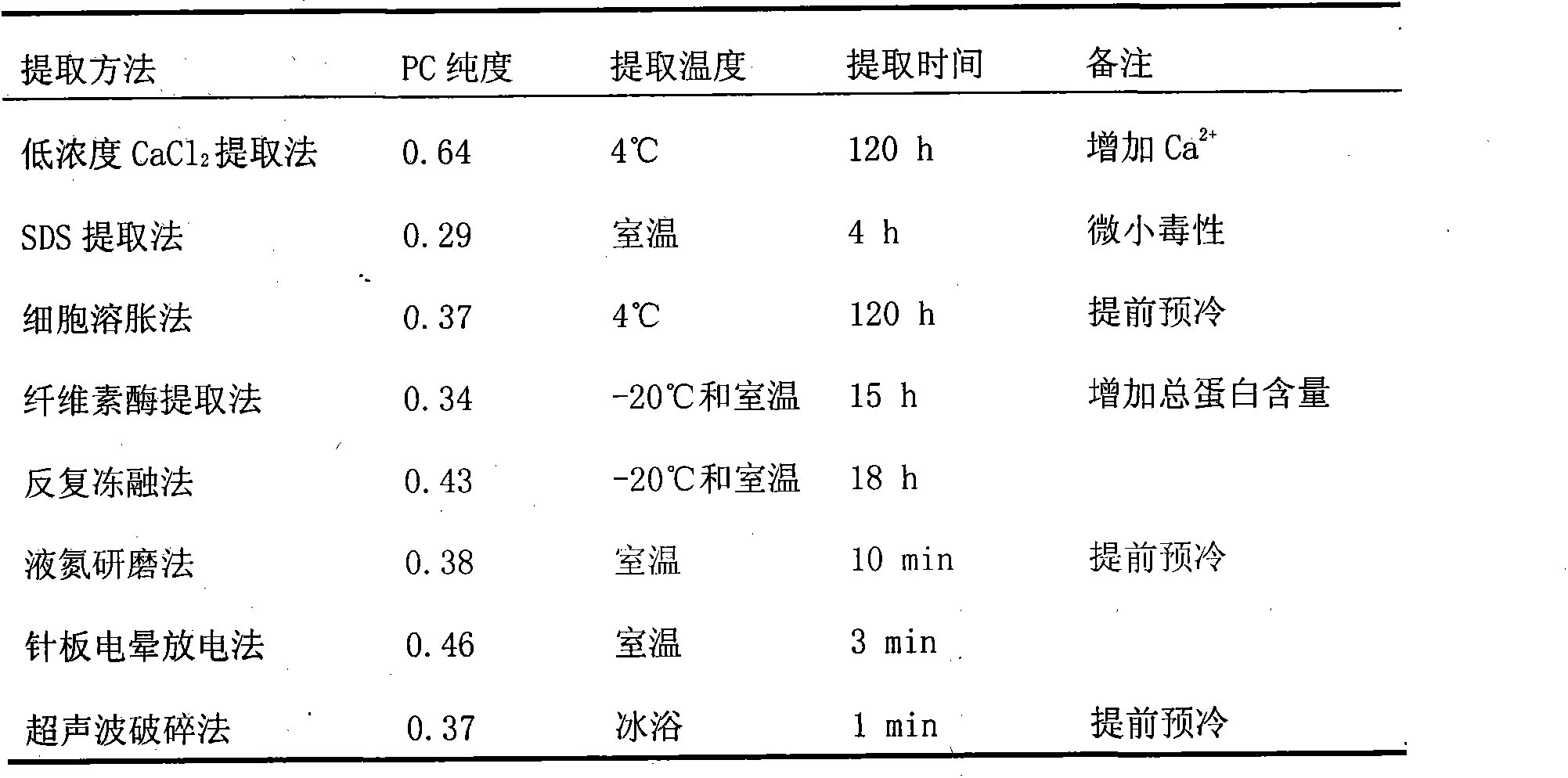

[0021] Record and count the results of the early cell crushing treatment by the pin-plate corona discharge method and other methods, and the specific results are shown in Table 1:

[0022] Table 1 is the result of algae cell crushing treatment by different methods

[0023]

[0024] low concentration of CaCl 2 The h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap