Corrosion inhibitor for high-carbon-dioxide and high-hydrogen sulfide oilfield and preparation method thereof

A high carbon dioxide and corrosion inhibitor technology, applied in earth-moving drilling, wellbore/well components, etc., can solve the problems of poor corrosion inhibitor effect, difficult to obtain raw materials, high preparation cost, simple formula, wide application range, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

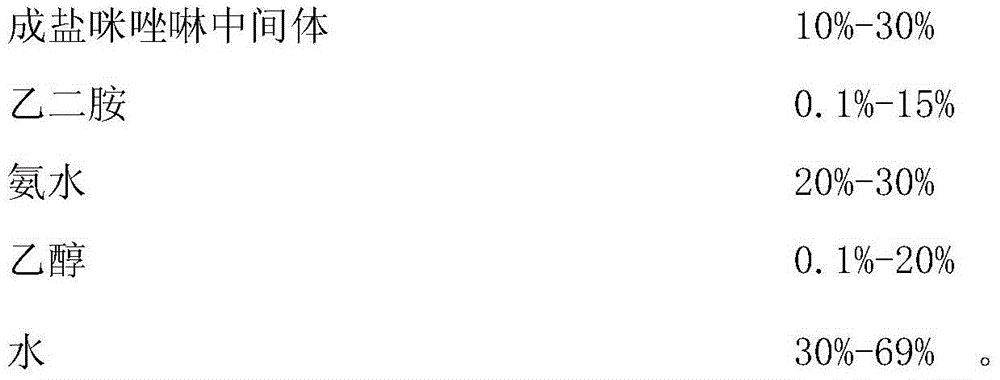

[0034] A compound corrosion inhibitor formula for high carbon dioxide and high hydrogen sulfide oilfields is as follows (mass percentage):

[0035]

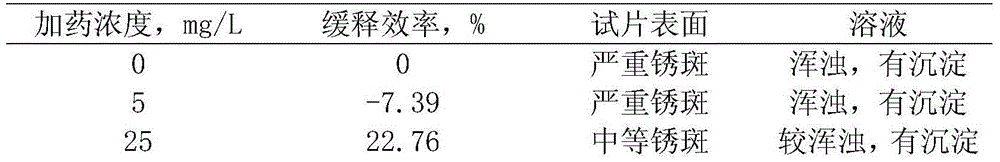

[0036] The static test temperature is 80°C, and the corrosion inhibitor is soaked in the corrosion coupon for 7 days. The corrosion inhibition effect is as follows:

[0037] Table 1 Sustained-release efficiency of different dosing concentrations

[0038]

[0039]

Embodiment 2

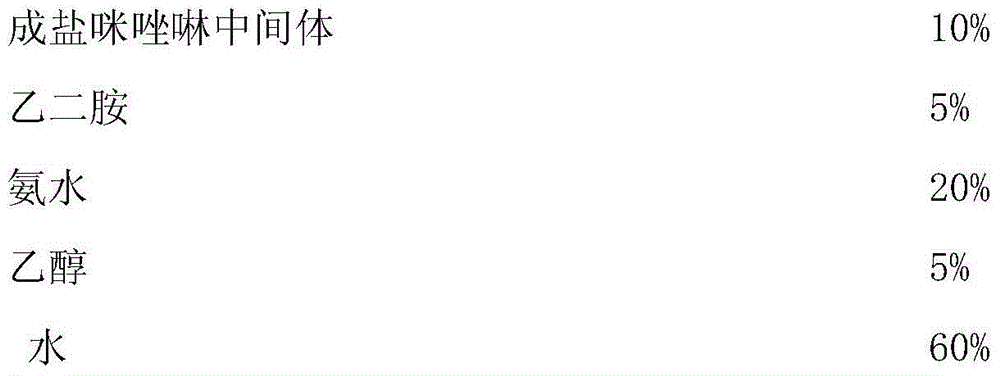

[0041] A compound corrosion inhibitor formula for high carbon dioxide and high hydrogen sulfide oilfields is as follows (mass percentage):

[0042]

[0043] The static test temperature is 80°C, and the corrosion inhibitor is soaked in the corrosion coupon for 7 days. The corrosion inhibition effect is as follows:

[0044] Table 2 Sustained-release efficiency of different dosing concentrations

[0045]

Embodiment 3

[0047] A compound corrosion inhibitor formula for high carbon dioxide and high hydrogen sulfide oilfields is as follows (mass percentage):

[0048]

[0049] The static test temperature is 80°C, and the corrosion inhibitor is soaked in the corrosion coupon for 7 days. The corrosion inhibition effect is as follows:

[0050] Table 3 Sustained-release efficiency of different dosing concentrations

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com