Healthcare soft underwear fabric

An underwear fabric and soft technology, applied in underwear, application, clothing and other directions, can solve the problems of poor durability and weakened effect, and achieve the effect of excellent antibacterial performance, good affinity, soft and comfortable hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

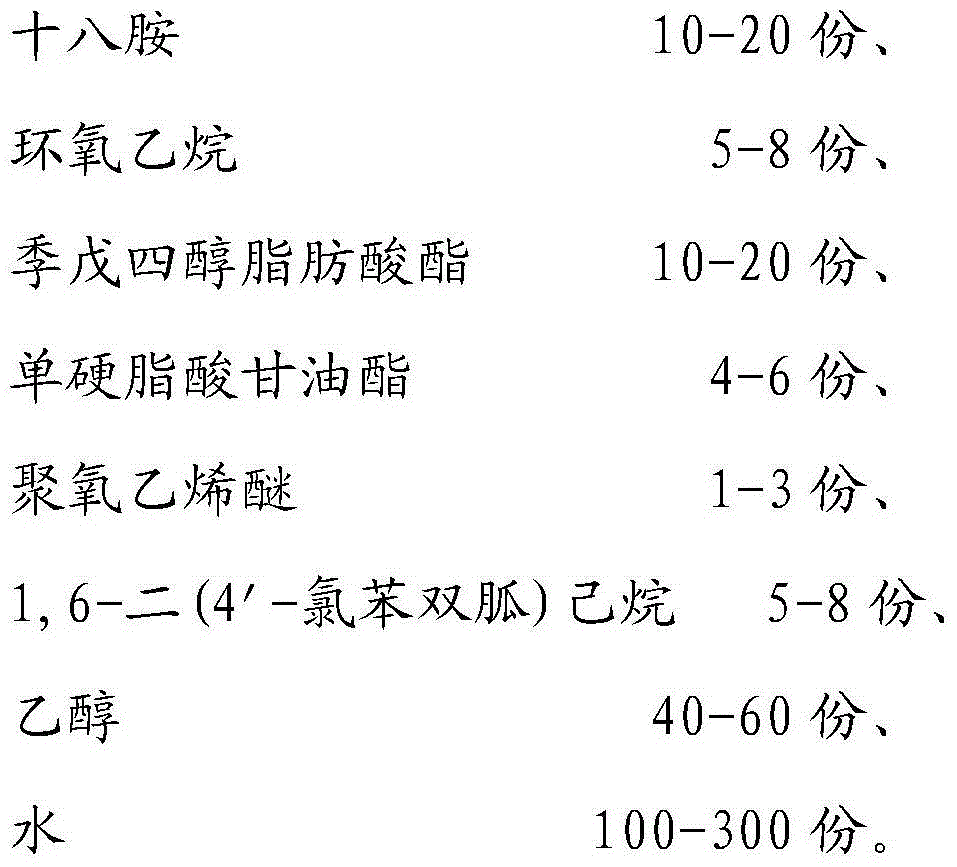

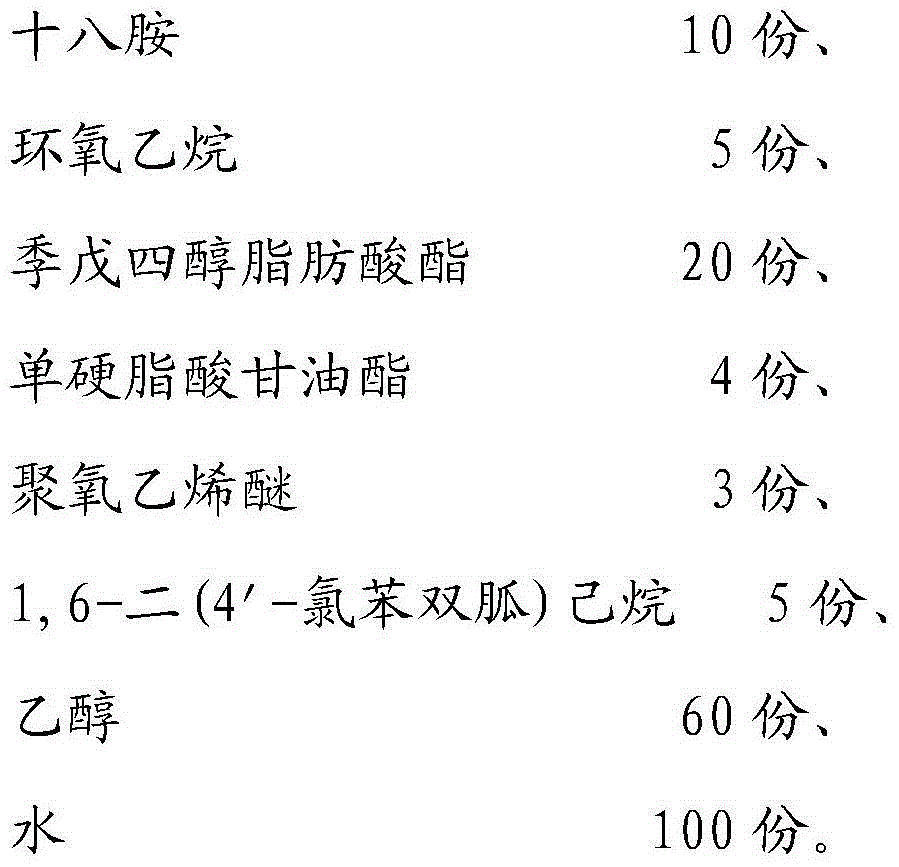

[0014] Composite softener composition:

[0015]

[0016] The composite softener is prepared as follows: (1) Mix 5 parts of 1,6-bis(4'-chlorohexidine)hexane, 3 parts of polyoxyethylene ether, 60 parts of ethanol and 100 parts of water; (2 ) Mix 10 parts of octadecylamine, 5 parts of ethylene oxide, 20 parts of pentaerythritol fatty acid ester, and 4 parts of glyceryl monostearate; (3) Slowly add the product obtained in step (1) to obtain in step (2) In the product, the feeding is completed within 1 to 2 hours, and the mixing is continued for 30 to 50 minutes.

[0017] Preparation of health care soft underwear fabric:

[0018] The underwear fabric blended with 55% cotton fiber, 30% soybean protein fiber, and 15% bamboo fiber was soaked in the soaking solution containing the above-mentioned composite softener for 30 minutes at 95°C; then the fabric was soaked at 130 0.5 hours between ℃ constant temperature.

Embodiment 2

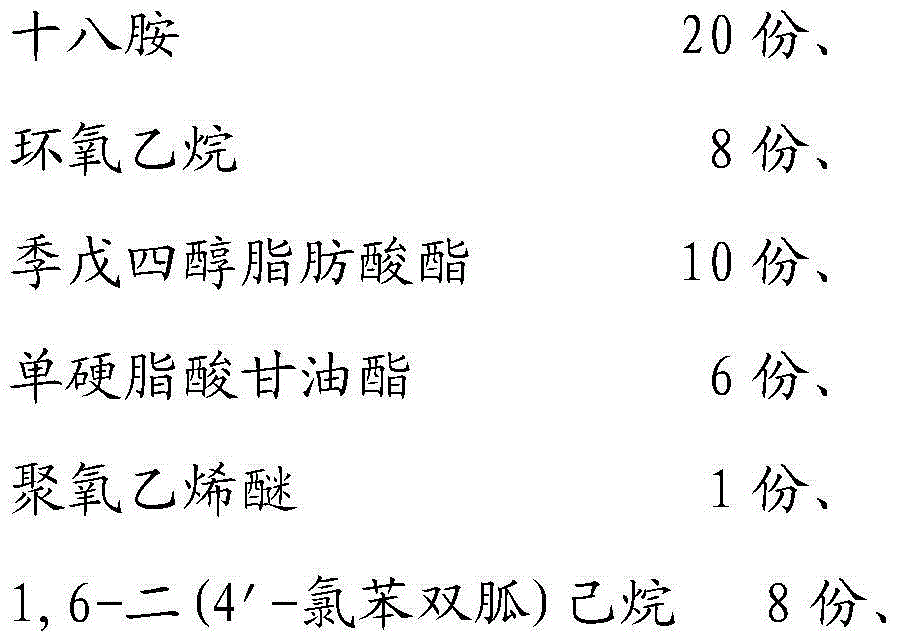

[0020] Composite softener composition:

[0021]

[0022]

[0023] The composite softener is prepared as follows: (1) Mix 8 parts of 1,6-bis(4'-chlorohexidine)hexane, 1 part of polyoxyethylene ether, 40 parts of ethanol and 300 parts of water; (2 ) Mix 20 parts of octadecylamine, 8 parts of ethylene oxide, 10 parts of pentaerythritol fatty acid ester, and 6 parts of glyceryl monostearate; (3) Slowly add the product obtained in step (1) to obtain in step (2) In the product, the feeding is completed within 1 to 2 hours, and the mixing is continued for 30 to 50 minutes.

[0024] Preparation of health care soft underwear fabric:

[0025] The underwear fabric blended with 60% cotton fiber, 20% soybean protein fiber, and 20% bamboo fiber by mass percentage was immersed in the dipping solution containing the above-mentioned composite antibacterial agent for 30 minutes at 95°C; then the fabric was soaked at 130 0.5 hours between ℃ constant temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com