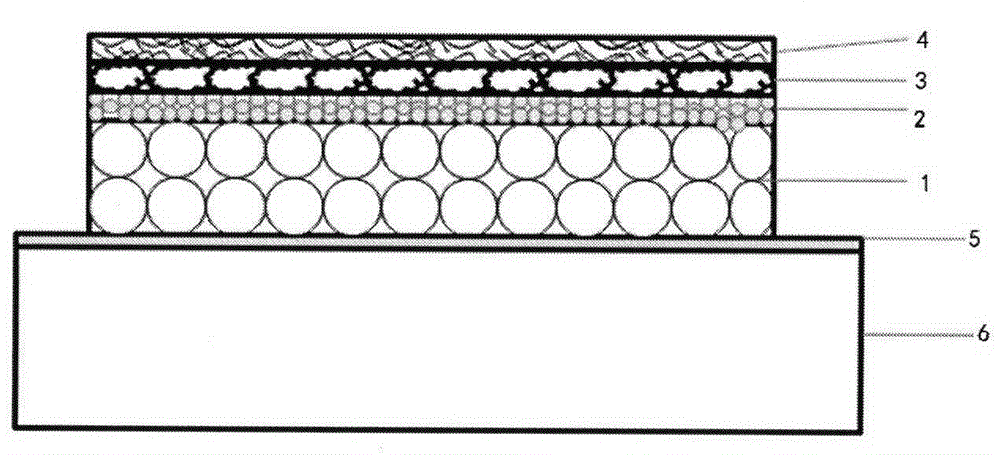

Multi-level hole TiO2/quantum dot/dye lamination thin-film solar cell photo-anode and preparation method thereof

A technology of solar cells and quantum dots, applied in photosensitive devices, circuits, capacitors, etc., can solve the problems of low efficiency of sensitized solar cells, achieve the effects of broadening the spectral response range, facilitating electron transmission, and high light absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

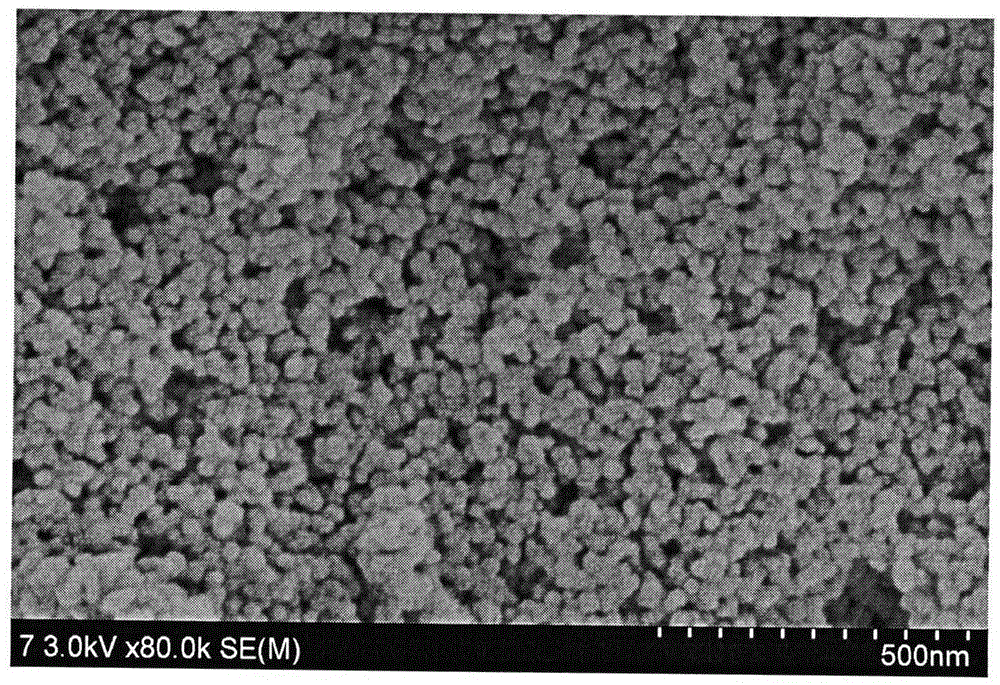

Embodiment 1

[0025] (1) Hierarchical Porous TiO 2 Preparation of semiconductor powder Add F127 to absolute ethanol (EtOH), stir until the solution is clear, then add TiCl dropwise 4 Continue to stir, the molar ratio of raw materials is F127:EtOH:TiCl 4 =1:3397:76, the stirring temperature is 40°C, then put the obtained precursor into a hydrothermal kettle and heat it at 160°C for 16 hours; after filtering and drying, it is heat-treated and kept at 300°C for 90 minutes. Heat at 500°C for 240 minutes, heat at 610°C for 10 minutes, and anneal. Add the prepared titanium dioxide powder into the dilute nitric acid solution with a mass ratio of 1:20, stir at 80°C for 10 hours, and then rotary evaporate to dryness at 90-100°C. (2) Hierarchical Porous TiO 2 The preparation of semiconductor thin film will the nano-TiO prepared by the above-mentioned hydrothermal method 2 The powder was added to EtOH and H 2 In the mixed solution of O (volume ratio 3:1), stir for 30 minutes; then add polyethylen...

Embodiment 2

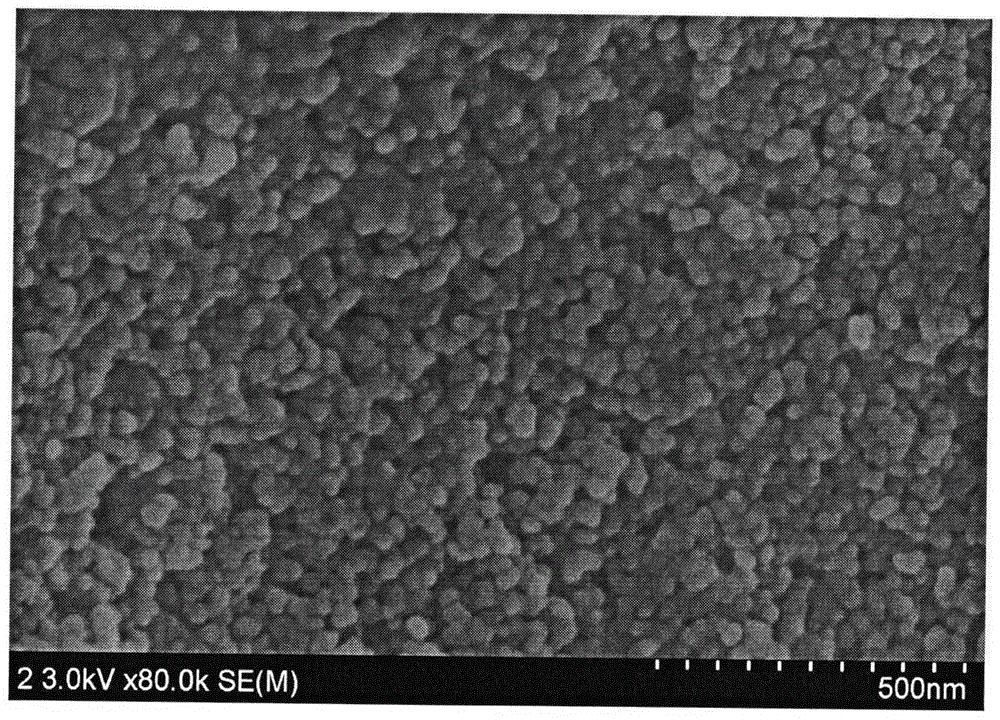

[0027] (1) Hierarchical Porous TiO 2 The preparation of the semiconductor layer is as in Example 1. (2) Prepare quantum dots and sensitize TiO 2 Thin film: TiO 2 Substrates were sequentially immersed in InCl 3 Aqueous solution (0.1mol / L), Na 2 S aqueous solution (1mol / L), CuCl 2 Aqueous solution (0.1mol / L), the immersion time is 60s, 120s, 60s respectively, before each immersion, the TiO 2 The substrate was rinsed with deionized water, cycled 8 times, dried and then roasted. The roasting method was 30min and 60min at 300°C and 500°C, respectively, and the heating rate was 2°C / min. Hierarchical TiO 2 / Quantum dot film is prepared by dipping and pulling film method to prepare a layer of In 2 S 3 Thin film: TiO with quantum dots will be prepared 2 The films were sequentially immersed in InCl 3 Aqueous solution (0.01-1mol / L), Na 2 S aqueous solution (0.01-1mol / L), the immersion time is 5-300s, it is rinsed with deionized water before each immersion, cycled 1-50 times, a...

Embodiment 3

[0028] Hierarchical Porous TiO 2 The preparation of semiconductor layer is the same as embodiment 1, quantum dot sensitized TiO 2 The film is as in Example 3, but without dye adsorption, the photoelectric conversion efficiency of the assembled cell is 1.14×10 -3 %, the open circuit voltage is 0.042V, and the short circuit current density is 9.5×10 -S mA / cm 2 . Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com