Preparation method of mixed egg liquid and egg liquid obtained through preparation method

A blended, egg liquid technology, applied in the field of egg product processing, can solve the problems of easily changing protein due to heat, limit product sales radius, and small market capacity, and achieve unique economical, energy-saving, and long-term shelf life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

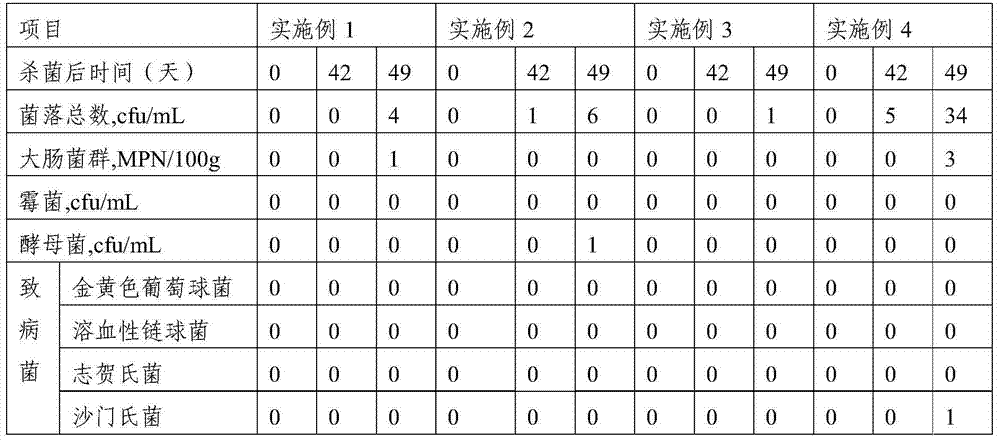

Embodiment 1

[0039] The method for cold sterilization preparation and deployment of protein solution, the steps are:

[0040] Take fresh eggs within seven days, wash, test, select, sterilize and air-dry with ultraviolet rays, beat the eggs to separate the protein liquid, filter with a 60-mesh filter, and homogenize with an XHF-D high-speed disperser;

[0041] The amount of sodium caseinate added is 0.2% of the mass of the egg liquid. Weigh the sodium caseinate according to the above ratio. According to the mass ratio of sodium caseinate and egg liquid is 1:2, take part of the egg liquid and mix it until completely Dissolve, then add the remaining egg liquid;

[0042] Pack the egg liquid into sterile plastic bags with lids, seal the lid after filling, and turn on the cooler and constant temperature water bath of the intermittent high-density carbon dioxide processor to make the cooling water and constant temperature water reach 4°C and 40°C respectively ; After that, turn on the water bath...

Embodiment 2

[0046] Take the fresh eggs produced on the day, wash, test, select, sterilize with ultraviolet light and air-dry, beat the eggs to separate the protein liquid, filter with a 60-mesh filter, and homogenize with an XHF-D high-speed disperser;

[0047] The amount of sodium caseinate added is 0.2% of the mass of egg liquid, the amount of carboxymethyl cellulose added is 0.02% of the mass of egg liquid, the amount of hydroxypropyl starch added is 0.02% of the mass of egg liquid, and the amount of maltodextrin The amount of addition is 0.1% of the mass of egg liquid. Weigh sodium caseinate, carboxymethyl cellulose, hydroxypropyl starch, and maltodextrin according to the above ratio. Mix the egg liquid with it, stir until evenly dispersed, then add the remaining egg liquid;

[0048] Pack the egg liquid into sterile plastic bags with lids, turn on the cooler and constant temperature water bath of the intermittent high-density carbon dioxide processor, and make the cooling water and co...

Embodiment 3

[0052] Take fresh eggs within seven days, wash, test, select, sterilize with ultraviolet light and air-dry, beat the eggs to separate the protein liquid, filter with a 60-mesh filter, and homogenize with an XHF-D high-speed disperser;

[0053] The amount of sodium caseinate added is 0.2% of the mass of the egg liquid, the amount of carboxymethyl cellulose added is 0.02% of the mass of the egg liquid, the amount of hydroxypropyl starch added is 0.02% of the mass of the egg liquid, the addition of maltodextrin The amount is 0.1% of the mass of egg liquid. Weigh sodium caseinate, carboxymethyl cellulose, hydroxypropyl starch, and maltodextrin according to the above ratio. Mix it with the liquid, stir until evenly dispersed, and then add the remaining egg liquid;

[0054] Pack the egg liquid into sterile plastic bags with lids, turn on the cooler and constant temperature water bath of the intermittent high-density carbon dioxide processor, and make the cooling water and constant t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com