Preparation method and application of metal organic framework thin film on surface of macroporous high polymer hollow fiber pipe

A high-molecular polymer and metal-organic framework technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as high cost, low stability, and restrictions on industrialized large-scale production, so as to expand the scope of application, The effect of low cost and easy large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

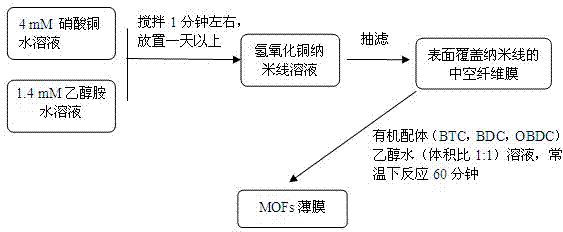

[0036] 1) Under magnetic stirring, add 1.4 mM ethanolamine aqueous solution to the same volume of 4 mM copper nitrate, zinc nitrate or cadmium nitrate aqueous solution, after 1 minute, slow down the stirring speed, and seal the reaction vessel, 24 hours, 1 hour, 1 After one hour, obtain copper hydroxide, zinc hydroxide or cadmium hydroxide nanowire solutions respectively, and soak the porous polymer hollow fiber membrane with one end closed and the other end connected to the suction filter pump into the solution containing nanowires for 30 minutes Finally, a nanowire layer with a thickness of 5 μm is obtained on its surface;

[0037] 2) Add the nanowire layer to a mixed solution containing 10 ml of trimesic acid at a concentration of 20 mM and ethanol water (volume ratio 1:1), and react at room temperature for 60 minutes to obtain a metal-organic framework with a thickness of 5 μm object film.

Embodiment 2

[0039] 1) Under magnetic stirring, add 1.4 mM ethanolamine aqueous solution to the same volume of 4 mM copper nitrate, zinc nitrate or cadmium nitrate aqueous solution. After 1 minute, slow down the stirring speed and seal the reaction vessel. After 24 hours, the Copper, zinc hydroxide or cadmium hydroxide nanowire solution, the porous polymer hollow fiber membrane with one end closed and the other end connected to the suction filter pump is immersed in the solution containing nanowires, and a thickness of 10 μm is obtained on the surface after 60 minutes nanowire layer;

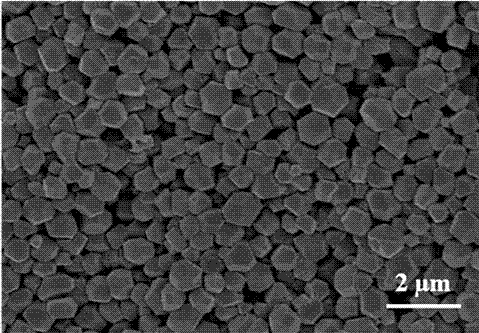

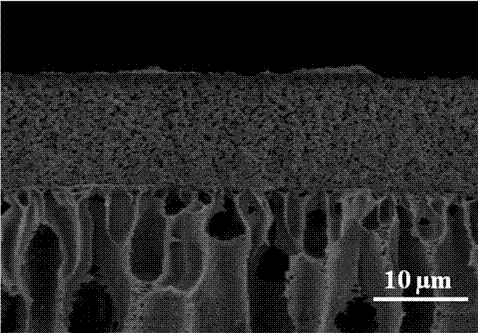

[0040]2) Add the nanowire layer to a mixed solution containing 15 ml of 10 mM trimesic acid solvent and ethanol water (volume ratio 1:1), react at room temperature for 60 minutes, and obtain a 10 μm thick metal organic layer Frame film, see figure 2 , image 3 .

Embodiment 3

[0042] 1) Under magnetic stirring, add 1.4 mM ethanolamine aqueous solution to the same volume of 4 mM copper nitrate, zinc nitrate or cadmium nitrate aqueous solution, after 1 minute, slow down the stirring speed, and seal the reaction vessel, 24 hours, 1 hour, 1 After one hour, obtain copper hydroxide, zinc hydroxide or cadmium hydroxide nanowire solutions respectively, and soak the porous polymer hollow fiber membrane with one end closed and the other end connected to the suction filter pump into the solution containing nanowires for 60 minutes Finally, a nanowire layer with a thickness of 10 μm is obtained on its surface;

[0043] 2) Add the nanowire layer to a mixed solution containing 18ml of 20mM trimesic acid solvent and ethanol water (1:1 volume ratio), react at room temperature for 60 minutes, and obtain a 10μm thick metal organic framework film, see Figure 4 , Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com