Isoparaffin solvent oil recovery method

A technology for isoparaffin solvent oil and catalyst, which is used in chemical instruments and methods, catalysts for physical/chemical processes, and only multi-stage series refining process treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

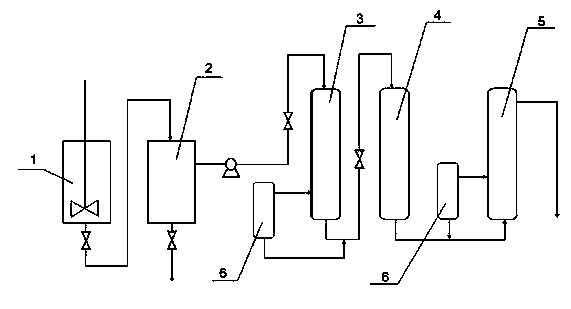

Image

Examples

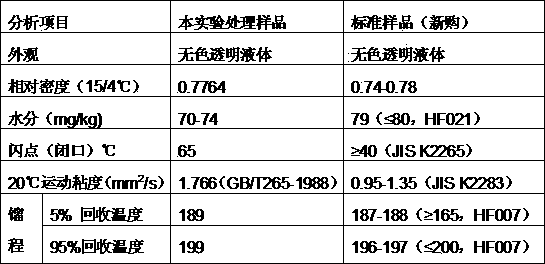

Embodiment 1

[0034] The present invention reclaims the used catalyst preparation method of isoparaffin solvent as follows:

[0035] Add 500 milliliters of deionized water to 100 grams of molybdenum oxide, add 50 grams of 85% phosphoric acid, heat to dissolve, add 50 grams of copper carbonate to the solution, heat and stir to dissolve, then add alumina (activated alumina with a diameter of about 3 microns) Ball, specific surface area 170sqm / g, pore volume 0.8ml / g), after standing still overnight, transfer the solution into a round bottom flask, evaporate the water with a rotary evaporator, move the alumina ball into a high-temperature oven, and introduce oxygen Sintering is carried out under the condition of 100-500°C for 5 hours. The desired catalyst Mo-Cu-PO prepared 4 , BET / N2 specific surface area is 170m 2 / g.

Embodiment 2

[0037] The present invention reclaims the used catalyst preparation method of isoparaffin solvent as follows:

[0038] Add 500 milliliters of deionized water to 100 grams of molybdenum oxide, add 50 grams of 85% phosphoric acid, heat to dissolve, add 50 grams of copper carbonate to the solution, heat and stir to dissolve, then add alumina (activated alumina with a diameter of about 6 microns) Ball, specific surface area 170sqm / g, pore volume 0.8ml / g), after standing still overnight, transfer the solution into a round bottom flask, evaporate the water with a rotary evaporator, move the alumina ball into a high-temperature oven, and introduce oxygen Sintering is carried out under the condition of 100-500°C for 5 hours. The desired catalyst Mo-Cu-PO prepared 4 , BET / N2 specific surface area is 170m 2 / g.

Embodiment 3

[0040] step 1

[0041] 500g of Isopar solvent directly recovered from the factory, add 100ml of 30% mass concentration hydrogen peroxide aqueous solution, stir for 10h, separate the organic layer, wash the organic layer with 10% sodium carbonate solution, and dry the organic layer with a small amount of about 50 grams of sodium sulfate for 1 Hour.

[0042] step 2

[0043] The Mo-Cu-PO catalyst that above-mentioned embodiment prepares is this solvent treatment catalyst, and experimental operation is as follows: 50 centimeters are long, 1 inch diameter stainless steel vertical fixed reaction tubes are filled with 20 grams of above-mentioned catalysts, after step 1 is processed with pump The organic layer is slowly poured into this vertical fixed reaction tube, the flow rate is 10ml / min, the temperature of the reaction tube wall is heated to 150°C, and the product of catalytic reaction treatment slipping out is collected.

[0044] step 3

[0045] Long 50 centimeters, 500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com