Thermosetting resin composition and application thereof

A resin composition and thermosetting technology, applied in the fields of resin glue, prepreg and laminate, can solve the problems affecting the insulation performance of copper clad laminates, and achieve the effects of improving mechanical properties, less content and reducing light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

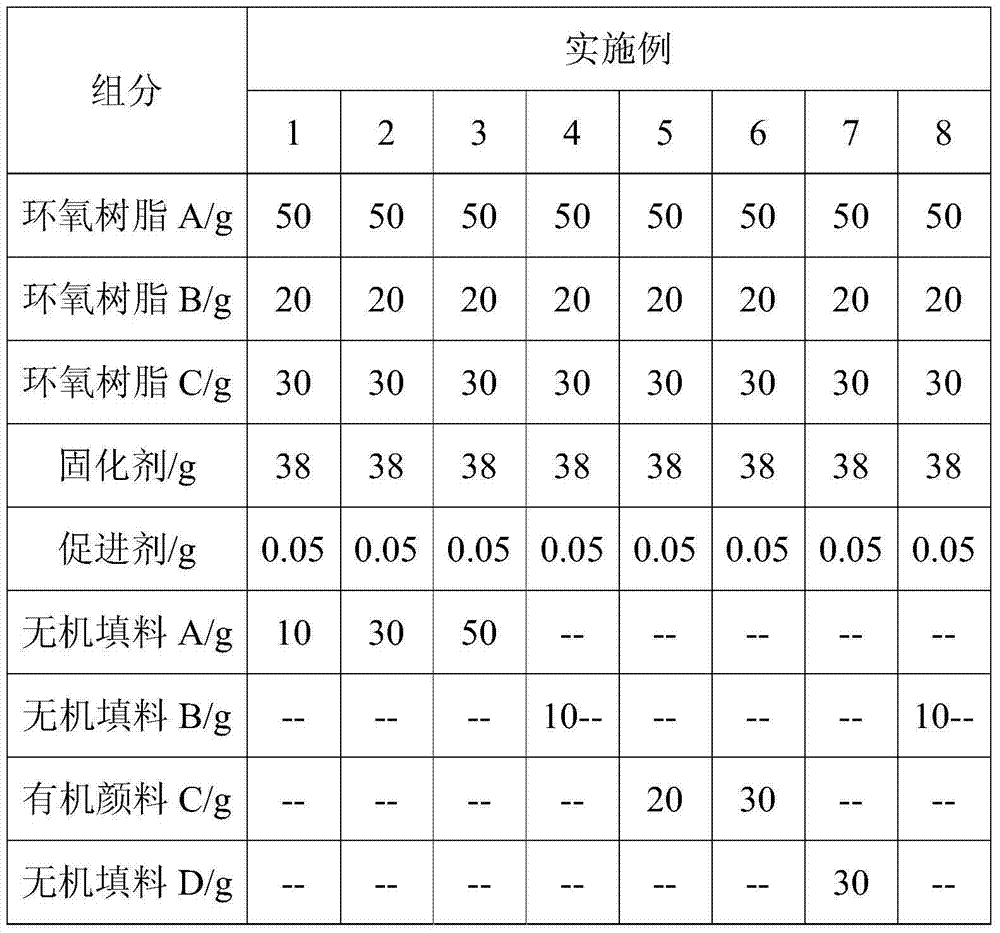

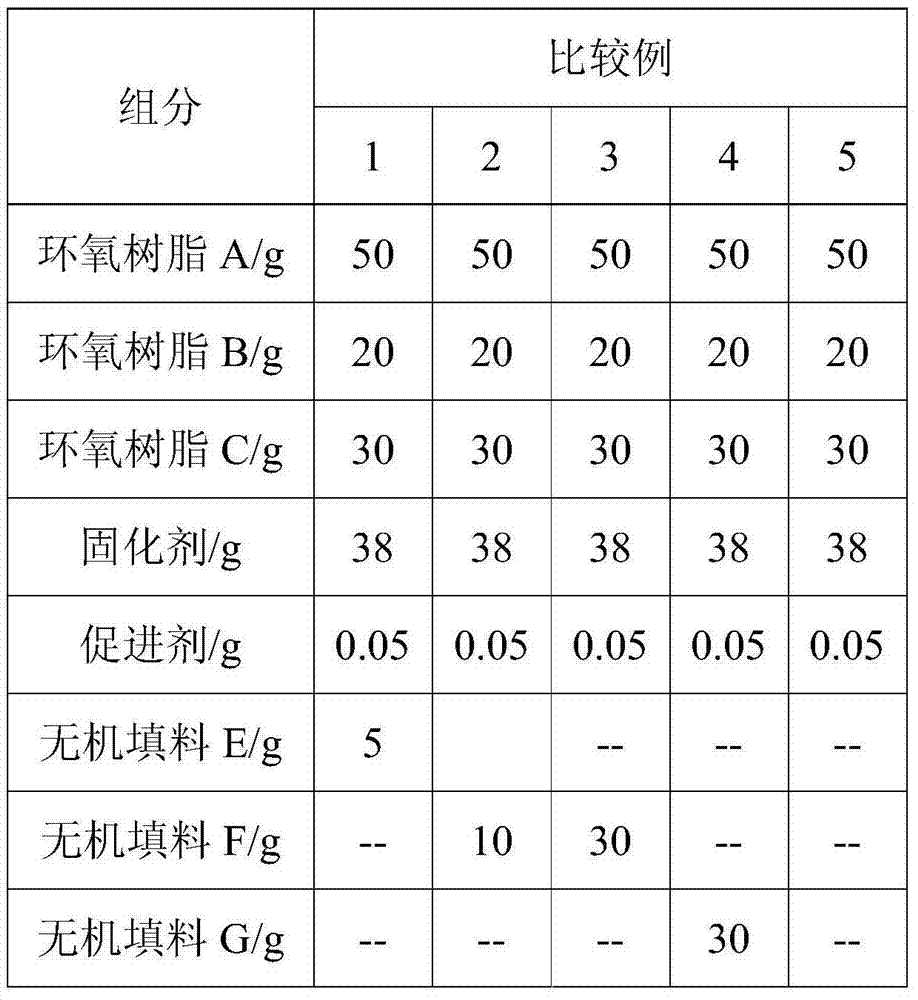

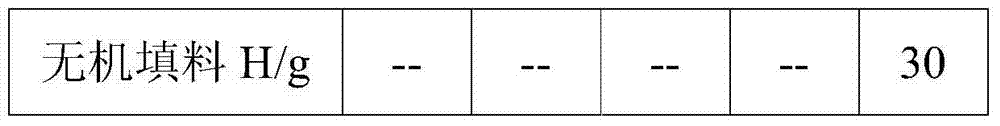

Embodiment 1-8

[0055] Examples 1-8 The solid component formula composition is shown in Table 1, and methyl ethyl ketone is used to prepare a thermosetting epoxy resin glue used in the manufacture of laminates, wherein the solid component accounts for 67%.

[0056] The copper clad substrates of Examples 1-8 were prepared according to the following preparation process:

[0057] (1) Glue making: Add the solvent into the batching container, add epoxy resin, curing agent solution and curing accelerator solution respectively under stirring; after stirring for 2 hours, add inorganic filler, continue stirring for 4-8 hours, then take a sample test The gelling time of the glue (170°C constant temperature hot plate) is 200-300 seconds.

[0058] (2) Impregnation: Pass the reinforced material layer soaked in glue through a vertical or horizontal impregnation machine, and control the extrusion wheel speed, line speed, wind temperature and furnace temperature. The specific example of the vertical impregna...

Embodiment 8

[0065] The difference between embodiment 8 and embodiment 4 is that the reinforcing material used in embodiment 8 is coated with graphene oxide, the quality of graphene oxide is 0.5wt% of the quality of the reinforcing material, the thickness of graphene oxide is 2 nanometers, and the average width 0.1 micron, the reinforcing material used in Example 4 has not been treated with graphene oxide, and the rest are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com