Chlorella Chlorella sp.HQ culture method and application in water purification and oil production

A technology of water quality purification and cultivation methods, applied in chemical instruments and methods, methods based on microorganisms, biochemical equipment and methods, etc., can solve problems such as water bloom outbreaks, achieve protection of water resources, reduce cultivation costs, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

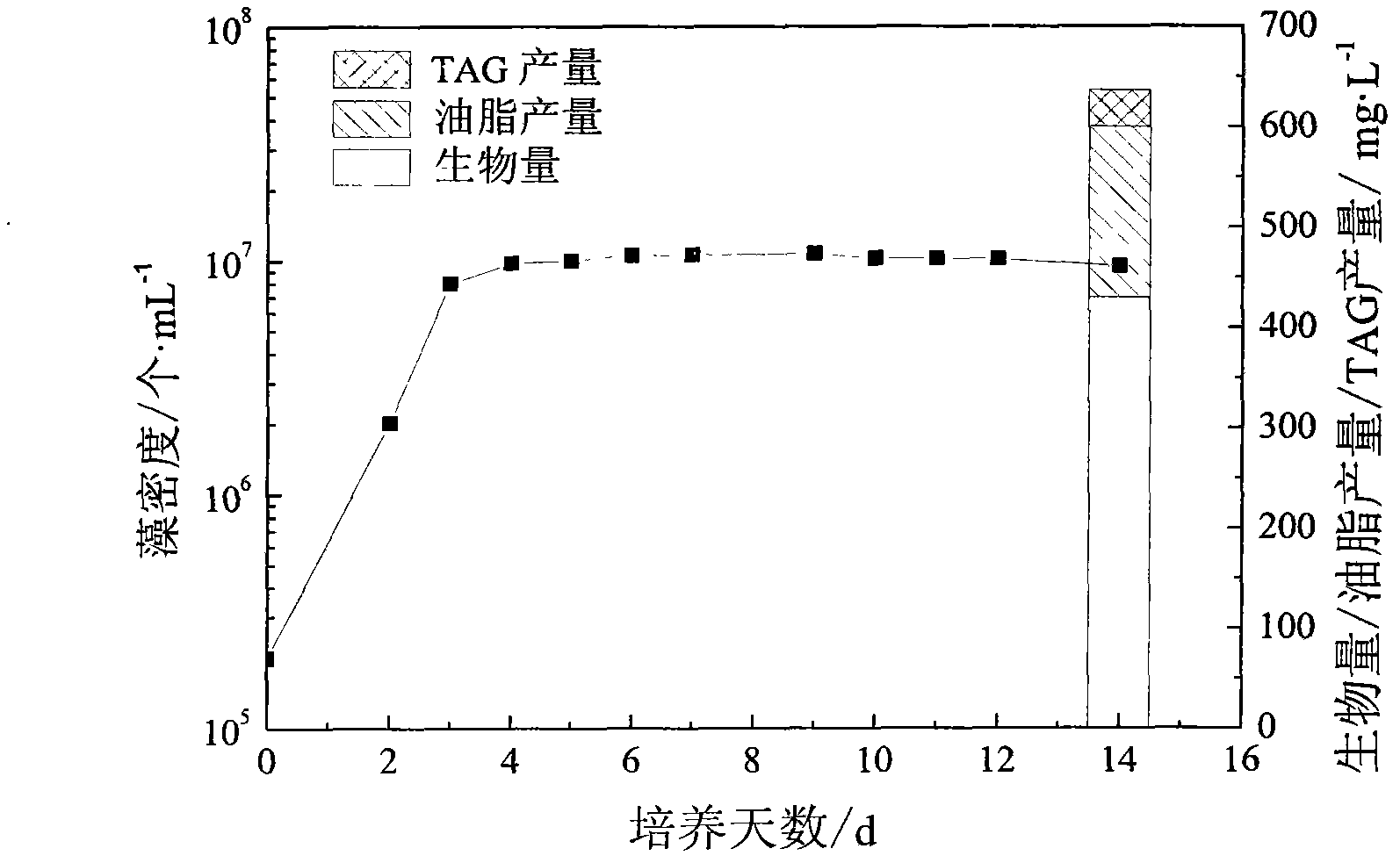

[0024] Chlorella HQ was inoculated in the secondary effluent of Beijing Qinghe Sewage Treatment Plant with an initial inoculation density of 5×10 4 pcs mL -1 , the light-to-dark ratio is 12:12, the temperature is 20°C, and the light intensity is 40μmol·(m 2 s) -1 The growth curve, biomass, oil production and TAG production of Chlorella were measured after culturing for about 14 days. Centrifuge at 4500rpm for 15min after the culture is over to obtain algae.

[0025] The result is as figure 1 As shown, the maximum density of chlorella growing in the secondary effluent of Qinghe sewage treatment plant can reach 10 6 pcs mL -1 , the biomass can be as high as 98mg·L -1 , the oil production can be as high as 41.6mg·L -1 , TAG production can be as high as 18.7mg·L -1 .

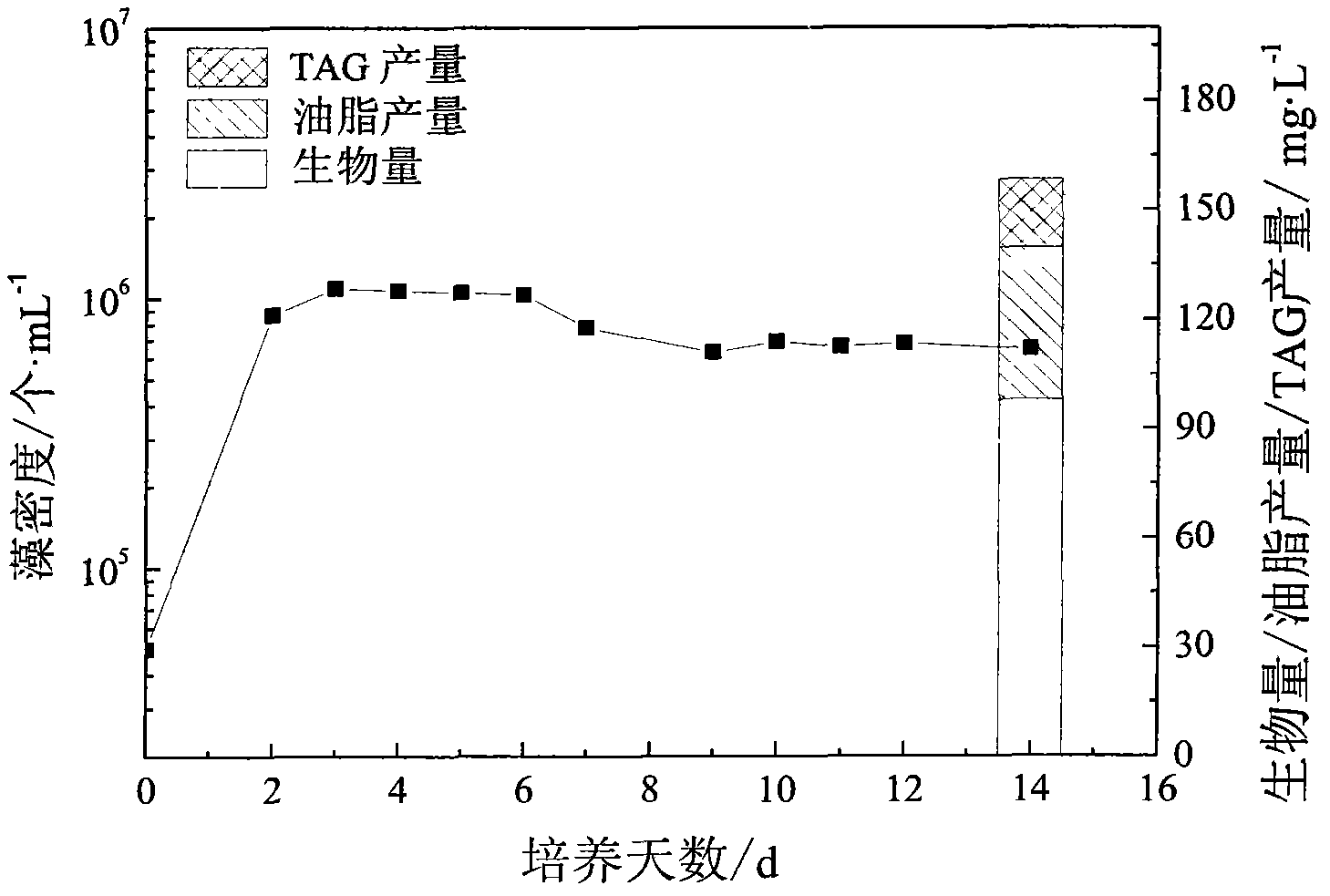

[0026] Chlorella HQ was inoculated in the secondary effluent of Beijing Xiaojiahe Wastewater Treatment Plant with an initial inoculation density of 2×10 5 pcs mL -1 , the light-to-dark ratio is 13:11, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com