Ultra-high temperature pulverized coal combustion experiment device

A technology of pulverized coal combustion and experimental equipment, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as unadjustable hot air temperature, intermittent injection, and small hot air flow rate, and achieve low hot air speed. Accurate and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

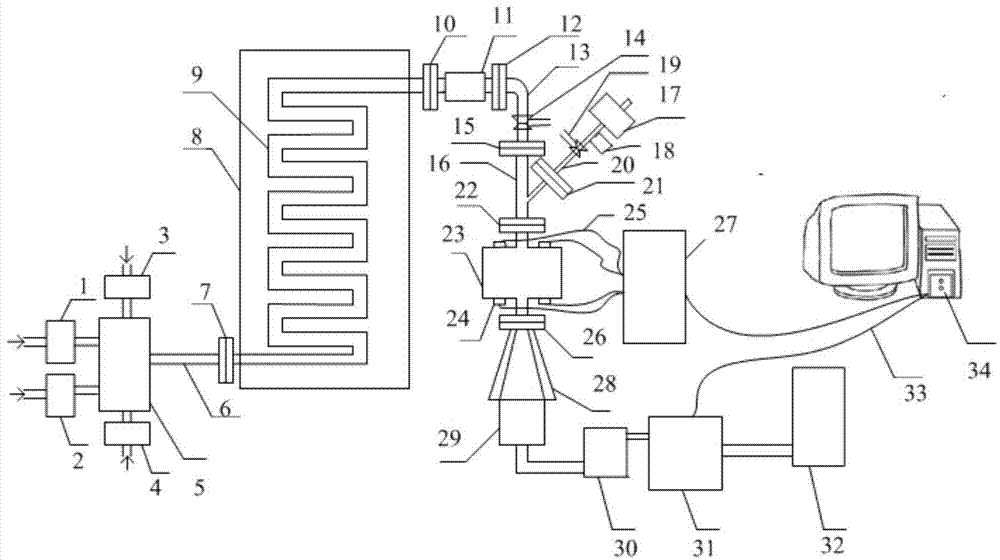

[0020] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0021] 1. If figure 1 As shown, the above-mentioned experimental device for ultra-high temperature pulverized coal combustion is characterized in that it includes an oxygen flow meter (1), a hydrogen gas flow meter (2), a carbon monoxide gas flow meter (3), and a carbon dioxide gas flow meter (4) , gas mixing tank (5), air duct (6), sealing flange four (7), gas preheating furnace (8), superalloy tube (9), sealing flange five (10), gas accelerator (11) , Sealing flange six (12), air duct (13), quick shut-off valve one (14), sealing flange one (15), mixing tube (16), inert gas flow meter (17), coal powder screw feed device (18), quick cut-off valve two (19), coal delivery pipe (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com