Method for treating recirculated cooling water containing sulfur

A technology of circulating cooling water and treatment method, which is applied in the treatment field of suppressing the corrosiveness of sulfur-containing circulating cooling water, which can solve the problems of non-renewable recycling, aggravation of water quality nutrition, and environmental pollution, so as to save the cost of chemicals and improve eutrophication The effect of globalization and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment adopts 20 # Carry out the corrosion test of the rotating coupon on carbon steel, refer to HG / T2159-91, the test temperature is 50 ℃, the speed is 75 rpm, and the operation is 72 hours.

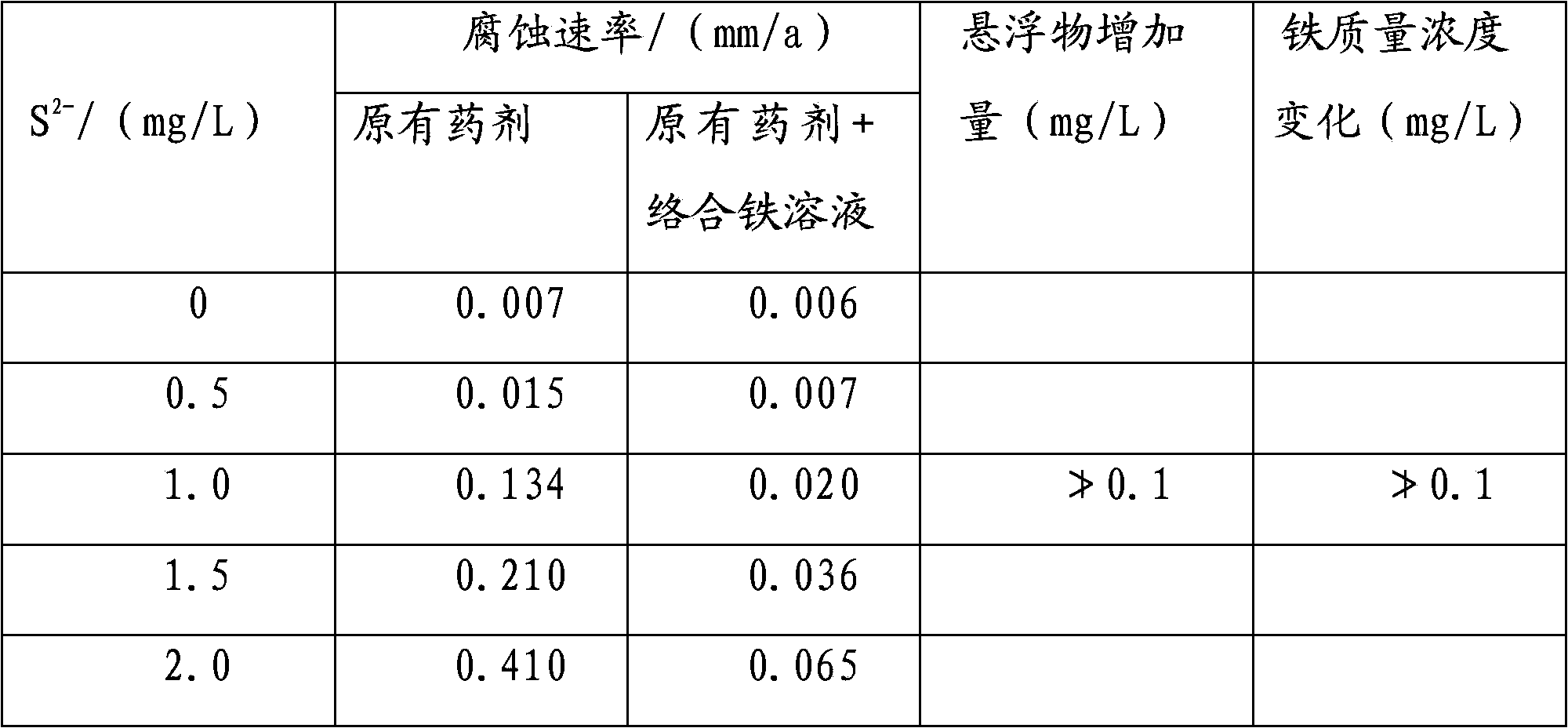

[0024] Circulating cooling water quality of an oil refinery: calcium hardness 250mg / L, total alkalinity 250mg / L, Cl - 40mg / L, SO 4 2- 30mg / L, with NaHCO 3 Adjust its alkalinity to 320mg / L, and add different concentrations of Na 2 S, then add 960mg / L iron complex solution (6% iron nitrate, 5% EDTA tetrasodium salt, 5% nitrilotriacetic acid trisodium salt, 4% sorbitol, 80% deionized Water), the corresponding iron element mass concentration is 8mg / L, the results are shown in Table 1. It can be seen from Table 1 that after adding complex iron, the corrosion rate decreases, which can be as low as below 0.075mm / a. at 1mg / L S 2- For example, in the 72h test, the increase in suspended solids and the change in iron mass concentration were both below 0.1mg / L.

[0025] Tabl...

Embodiment 2

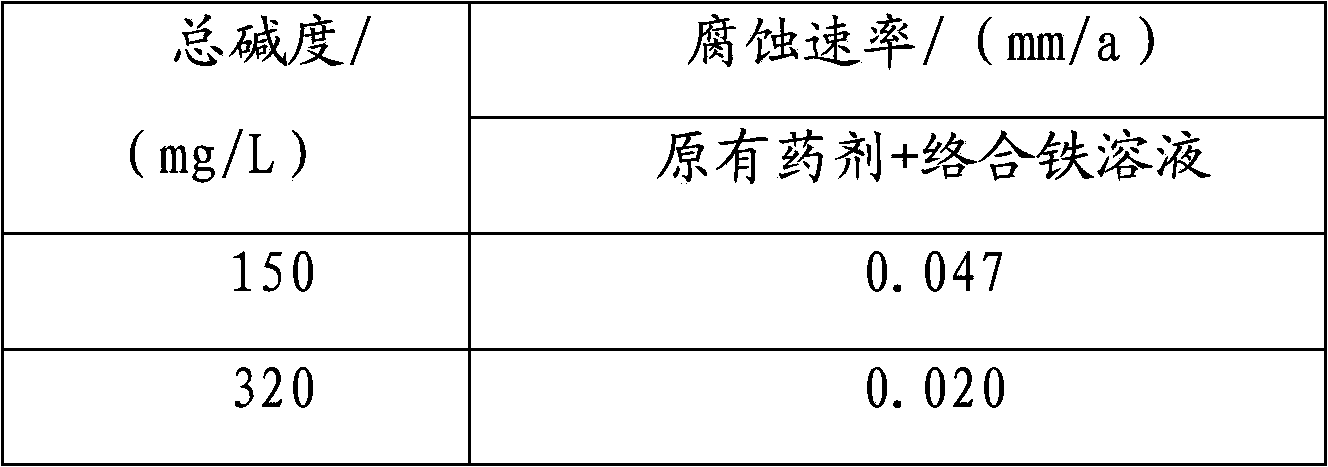

[0028] The present embodiment coupon corrosion test condition and circulating water quality parameter are the same as embodiment 1, with dilute H 2 SO 4 or NaHCO 3 Adjust its alkalinity to 150mg / L or 320mg / L, and add 1.0mg / L Na without changing the current chemical used in the refinery 2 S, then add 960mg / L iron complex solution (6% iron nitrate, 5% EDTA tetrasodium salt, 5% nitrilotriacetic acid trisodium salt, 4% sorbitol, 80% deionized Water), the corresponding iron element mass concentration is 8mg / L, the results are shown in Table 2. It can be seen from Table 2 that higher alkalinity is more conducive to reducing corrosion.

[0029] Table 2

[0030]

Embodiment 3

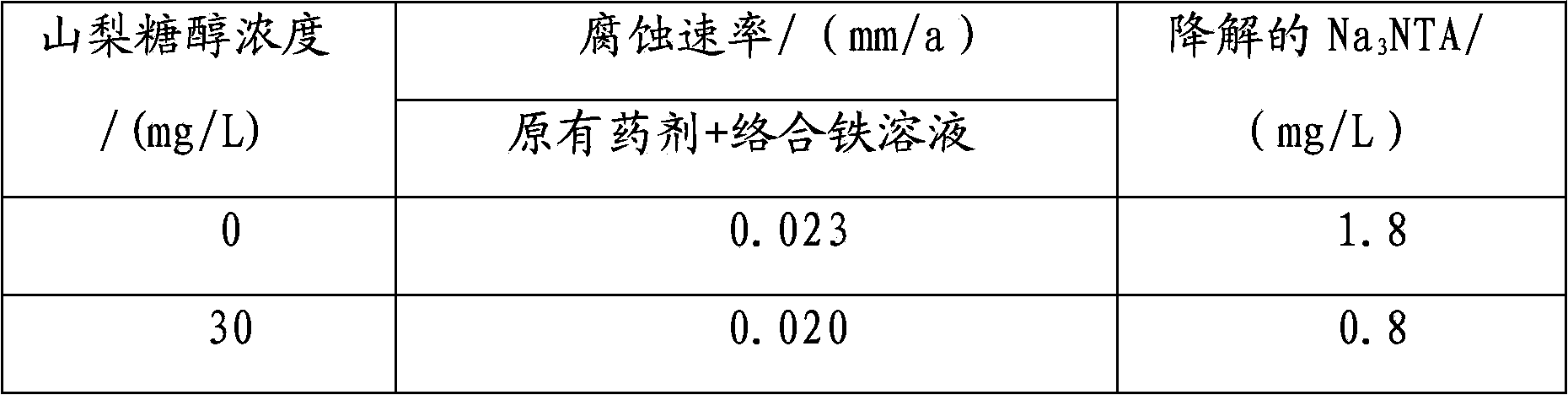

[0032]The present embodiment coupon corrosion test condition and circulating water quality parameter are the same as embodiment 1, with NaHCO 3 Adjust its alkalinity to 320mg / L, and add 1.0mg / LNa without changing the current chemical used in the refinery 2 S, then add 960mg / L iron complex solution (6% ferric nitrate, 10% nitrilotriacetic acid trisodium salt (Na 3 NTA), 84% deionized water), the corresponding iron concentration is 8mg / L. The added amount of sorbitol was 0 or 30mg / L respectively. Quantitatively analyze the filtrate after filtering circulating water to determine Na 3 Loss of NTA (determined by liquid chromatography for Na 3 Concentration changes of NTA). The results are shown in Table 3. It can be seen from Table 3 that the addition of sorbitol can reduce the degradation rate of α-amino acid.

[0033] table 3

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com